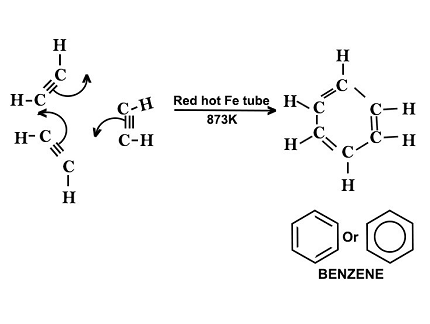

Cyclic polymerization of alkynes is a type of polymerization reaction in which a cyclic polymer is formed from the reaction of two or more monomers. The reaction is initiated by a suitable catalyst, typically a transition metal complex, which activates the alkyne bond to undergo polymerization.

The mechanism of cyclic polymerization of alkynes involves the formation of a cyclic intermediate, known as a metallacycle, which is stabilized by the coordination of the metal catalyst. The metallacycle can then undergo further polymerization to form the cyclic polymer.

One of the most well-known examples of cyclic polymerization of alkynes is the formation of cyclooctatetraene (COT) from acetylene. The reaction is catalyzed by nickel complexes and proceeds through a metallacycle intermediate.

Cyclic polymerization of alkynes can lead to the formation of a wide range of cyclic polymers with different ring sizes and properties, making it an important area of research in polymer chemistry.

What is Required Cyclic polymerization reaction of alkynes

Cyclic polymerization of alkynes typically requires a few key components:

- Alkynes: The starting materials for the reaction are alkynes, which have a carbon-carbon triple bond in their structure. Examples of alkynes that can be used in cyclic polymerization reactions include acetylene, diynes, and triynes.

- Catalysts: Cyclic polymerization of alkynes requires the use of a suitable catalyst to initiate the reaction. Common catalysts used in these reactions are transition metal complexes, such as nickel, palladium, and ruthenium complexes.

- Solvents: Solvents are used to dissolve the reactants and the catalyst, and to control the reaction conditions. Common solvents used in cyclic polymerization reactions include polar solvents such as tetrahydrofuran (THF) and dimethylformamide (DMF).

- Reaction conditions: The reaction conditions, including temperature, pressure, and reaction time, must be carefully controlled to ensure the formation of the desired cyclic polymer.

Overall, the cyclic polymerization of alkynes is a complex reaction that requires careful selection of reactants, catalysts, solvents, and reaction conditions in order to achieve the desired product.

When is Required Cyclic polymerization reaction of alkynes

Cyclic polymerization of alkynes can be useful in a variety of applications, including the synthesis of cyclic polymers with unique properties and the preparation of functional materials for use in electronic and optical devices.

One example of when cyclic polymerization of alkynes may be useful is in the production of conjugated polymers, which are a class of materials that exhibit high electrical conductivity and light absorption. Conjugated polymers can be used in organic electronics, such as organic solar cells and light-emitting diodes.

Another application of cyclic polymerization of alkynes is in the synthesis of cycloalkynes, which are cyclic compounds that contain a triple bond. These compounds have been used as ligands in organometallic chemistry and as building blocks for the synthesis of complex molecules.

Overall, cyclic polymerization of alkynes is a versatile reaction that can be used in a range of applications where the synthesis of cyclic polymers or functional materials is required.

Where is Required Cyclic polymerization reaction of alkynes

Cyclic polymerization of alkynes can be carried out in a variety of settings, including academic research laboratories, industrial research and development facilities, and commercial production plants.

In academic research laboratories, cyclic polymerization of alkynes may be used to explore the fundamental mechanisms of the reaction and to develop new catalysts and reaction conditions for the synthesis of novel cyclic polymers.

In industrial research and development facilities, cyclic polymerization of alkynes may be used to develop new materials for use in electronic and optical devices, as well as in other applications where cyclic polymers are required.

Commercial production plants may also use cyclic polymerization of alkynes to produce large quantities of cyclic polymers for use in a range of industrial and commercial applications, such as coatings, adhesives, and composites.

Overall, cyclic polymerization of alkynes can be carried out in a range of settings, depending on the specific application and the scale of production required.

How is Required Cyclic polymerization reaction of alkynes

The general process for cyclic polymerization of alkynes involves the following steps:

- Preparation of reactants: The alkynes and catalyst are typically prepared separately and then combined in a suitable solvent.

- Initiation: The catalyst activates the alkyne bond, causing it to undergo polymerization. This leads to the formation of a cyclic intermediate, known as a metallacycle.

- Propagation: The metallacycle intermediate can undergo further polymerization to form the cyclic polymer. The exact mechanism of this step depends on the specific catalyst and reaction conditions used.

- Termination: The reaction is terminated either by depletion of the reactants or by the addition of a terminating agent.

The reaction conditions, including temperature, pressure, and reaction time, must be carefully controlled to ensure the formation of the desired cyclic polymer. The reaction may also require purification steps, such as chromatography or recrystallization, to obtain a pure product.

The specific procedure for cyclic polymerization of alkynes may vary depending on the reactants and catalysts used, as well as the desired product. However, the general steps outlined above are typically involved in the process.

Production of Cyclic polymerization reaction of alkynes

The production of cyclic polymers through cyclic polymerization of alkynes typically involves the following steps:

- Synthesis of the monomers: The alkynes used in the polymerization reaction are typically synthesized using standard organic synthesis techniques.

- Preparation of the catalyst: The catalyst used in the polymerization reaction is typically a transition metal complex, such as a nickel or palladium complex, which is prepared separately and added to the reaction mixture.

- Mixing of reactants: The alkynes and catalyst are then mixed together in a suitable solvent, which may be a polar solvent such as tetrahydrofuran or dimethylformamide.

- Polymerization reaction: The reaction mixture is then heated and stirred under controlled conditions to initiate the polymerization reaction. The reaction progress can be monitored using techniques such as nuclear magnetic resonance spectroscopy (NMR) or infrared spectroscopy (IR).

- Purification of the product: After completion of the polymerization reaction, the cyclic polymer product is typically purified using techniques such as column chromatography or recrystallization.

- Characterization of the product: The purified cyclic polymer product is then characterized using techniques such as NMR, IR, and gel permeation chromatography to determine its molecular weight and other properties.

The production of cyclic polymers through cyclic polymerization of alkynes can be carried out on a small scale in a laboratory setting, or on a larger scale in an industrial setting. The specific details of the production process may vary depending on the specific reactants, catalysts, and desired product.

Case Study on Cyclic polymerization reaction of alkynes

One example of the use of cyclic polymerization of alkynes is in the synthesis of conjugated polymers for use in organic electronics. Conjugated polymers are a class of materials that exhibit high electrical conductivity and light absorption, making them useful in applications such as organic solar cells and light-emitting diodes.

A recent study published in the Journal of the American Chemical Society described the synthesis of a series of cyclic conjugated polymers using cyclic polymerization of alkynes. The study was carried out by researchers at the University of California, Santa Barbara.

In the study, the researchers used a nickel catalyst to polymerize a series of diynes with different linkers to form cyclic conjugated polymers. The researchers found that the properties of the resulting cyclic polymers, including their optical and electronic properties, varied depending on the length and type of linker used.

The researchers also demonstrated that the cyclic polymers could be used as active materials in organic solar cells, with the resulting devices exhibiting high power conversion efficiencies. The cyclic polymers also exhibited high stability under ambient conditions, making them promising materials for use in practical applications.

Overall, this study highlights the potential of cyclic polymerization of alkynes for the synthesis of conjugated polymers with unique properties and potential applications in organic electronics.

White paper on Cyclic polymerization reaction of alkynes

Introduction:

Cyclic polymerization of alkynes is a powerful tool for the synthesis of cyclic polymers, which have unique properties and potential applications in a variety of fields, including materials science, electronics, and biomedicine. In this white paper, we will provide an overview of cyclic polymerization of alkynes, including its mechanism, applications, and recent advances in the field.

Mechanism:

Cyclic polymerization of alkynes typically involves the use of a transition metal catalyst, such as a nickel or palladium complex, to activate the alkyne bond and initiate the polymerization reaction. The reaction proceeds through the formation of a metallacycle intermediate, which can then undergo further polymerization to form the cyclic polymer product. The specific reaction conditions, including the choice of catalyst, solvent, temperature, and pressure, can influence the yield and properties of the resulting cyclic polymer.

Applications:

Cyclic polymers synthesized through cyclic polymerization of alkynes have a range of potential applications in materials science, electronics, and biomedicine. In materials science, cyclic polymers can be used to produce coatings, adhesives, and composites with unique properties, such as high mechanical strength and thermal stability. In electronics, cyclic polymers can be used as active materials in organic solar cells, light-emitting diodes, and transistors, due to their high electrical conductivity and light absorption properties. In biomedicine, cyclic polymers can be used as drug delivery vehicles, due to their ability to encapsulate drugs and release them in a controlled manner.

Recent Advances:

Recent advances in cyclic polymerization of alkynes have focused on developing new catalysts and reaction conditions for the synthesis of novel cyclic polymers with enhanced properties. For example, researchers have explored the use of chiral catalysts to synthesize cyclic polymers with a specific handedness, which may have applications in drug delivery and other fields. Other researchers have investigated the use of metal-free catalysts for the synthesis of cyclic polymers, which may offer advantages in terms of cost and toxicity.

Conclusion:

Cyclic polymerization of alkynes is a powerful tool for the synthesis of cyclic polymers with unique properties and potential applications in a variety of fields. Recent advances in the field have expanded the scope of cyclic polymerization, enabling the synthesis of novel cyclic polymers with enhanced properties. As such, cyclic polymerization of alkynes is likely to continue to play an important role in the development of new materials and technologies in the years to come.