Benzaldehyde can be synthesized from toluene or benzene using the following steps:

- Oxidation of Toluene/Benzene to Benzyl Alcohol: Toluene or benzene is first oxidized to benzyl alcohol using an oxidizing agent such as potassium permanganate or chromic acid. The reaction is typically carried out under reflux conditions.

- Oxidation of Benzyl Alcohol to Benzaldehyde: Benzyl alcohol is then oxidized to benzaldehyde using an oxidizing agent such as potassium permanganate or chromic acid. The reaction is typically carried out under reflux conditions.

The overall reaction can be represented as follows:

Toluene/Benzene + Oxidizing Agent → Benzyl Alcohol → Oxidizing Agent → Benzaldehyde

Note that this reaction requires careful handling of strong oxidizing agents, which can be dangerous if not handled properly. It is recommended to carry out the reaction under appropriate laboratory conditions with proper safety precautions.

What is Required Benzaldehyde from Toluene and Benzene

The amount of benzaldehyde required from toluene or benzene will depend on the specific application or reaction in which it will be used. However, if we assume a typical reaction, such as the synthesis of benzyl benzoate, which requires one mole of benzaldehyde and one mole of benzyl alcohol, we can calculate the amount of benzaldehyde needed.

For example, if we want to synthesize 1 mole of benzyl benzoate, we would need:

- 1 mole of benzyl alcohol

- 1 mole of benzaldehyde

To obtain 1 mole of benzaldehyde, we would need to oxidize 1 mole of toluene or benzene to produce 1 mole of benzaldehyde. The exact amount of toluene or benzene required will depend on the yield of the oxidation reaction, which can vary depending on the reaction conditions, oxidizing agent, and other factors.

In practice, it is common to use excess toluene or benzene to drive the reaction to completion and ensure a higher yield of benzaldehyde. The specific amount of excess toluene or benzene required will depend on the specific reaction conditions and the desired yield of benzaldehyde.

When is Required Benzaldehyde from Toluene and Benzene

Benzaldehyde can be used in various applications such as in the production of dyes, perfumes, flavorings, and pharmaceuticals. It is also used as a starting material in the synthesis of various organic compounds such as benzoic acid, benzyl alcohol, and benzyl benzoate.

Some specific examples of the uses of benzaldehyde are:

- In the perfume industry, benzaldehyde is used as a key ingredient in fragrances such as almond, cherry, and amaretto.

- In the food industry, benzaldehyde is used as a flavoring agent in foods such as baked goods, candies, and beverages.

- In the pharmaceutical industry, benzaldehyde is used as an intermediate in the synthesis of various drugs such as cinnarizine, which is used to treat vertigo and motion sickness.

- In the dye industry, benzaldehyde is used as a precursor in the synthesis of various dyes such as C.I. Solvent Yellow 2.

- In the agriculture industry, benzaldehyde is used as a pesticide for controlling insects and mites.

The specific application of benzaldehyde will depend on the industry and the intended use of the compound.

Where is Required Benzaldehyde from Toluene and Benzene

Benzaldehyde can be produced from toluene or benzene in chemical laboratories and industries that have the necessary equipment and expertise. The synthesis of benzaldehyde from toluene or benzene involves the use of strong oxidizing agents such as potassium permanganate or chromic acid, which requires careful handling and appropriate safety precautions.

Industries that commonly use benzaldehyde include the perfume, food, pharmaceutical, dye, and agriculture industries. Perfume manufacturers use benzaldehyde as a key ingredient in fragrances, while food manufacturers use it as a flavoring agent in various food products. The pharmaceutical industry uses benzaldehyde as an intermediate in the synthesis of various drugs, while the dye industry uses it as a precursor in the production of various dyes. The agriculture industry uses benzaldehyde as a pesticide for controlling insects and mites.

Benzaldehyde can be purchased from chemical suppliers, and it is also possible to synthesize it from toluene or benzene in-house if the necessary equipment and expertise are available.

How is Required Benzaldehyde from Toluene and Benzene

Benzaldehyde can be synthesized from toluene or benzene using a multi-step oxidation reaction that typically involves the use of strong oxidizing agents such as potassium permanganate or chromic acid. The reaction can be carried out using the following steps:

- Oxidation of Toluene/Benzene to Benzyl Alcohol: Toluene or benzene is first oxidized to benzyl alcohol using an oxidizing agent such as potassium permanganate or chromic acid. The reaction is typically carried out under reflux conditions.

- Oxidation of Benzyl Alcohol to Benzaldehyde: Benzyl alcohol is then oxidized to benzaldehyde using an oxidizing agent such as potassium permanganate or chromic acid. The reaction is typically carried out under reflux conditions.

The overall reaction can be represented as follows:

Toluene/Benzene + Oxidizing Agent → Benzyl Alcohol → Oxidizing Agent → Benzaldehyde

The specific reaction conditions and the choice of oxidizing agent may vary depending on the specific application and the desired yield of benzaldehyde. For example, some reactions may use a milder oxidizing agent such as manganese dioxide, while others may use a stronger oxidizing agent such as nitric acid.

The synthesis of benzaldehyde from toluene or benzene requires careful handling of strong oxidizing agents, which can be dangerous if not handled properly. It is recommended to carry out the reaction under appropriate laboratory conditions with proper safety precautions.

Nomenclature of Benzaldehyde from Toluene and Benzene

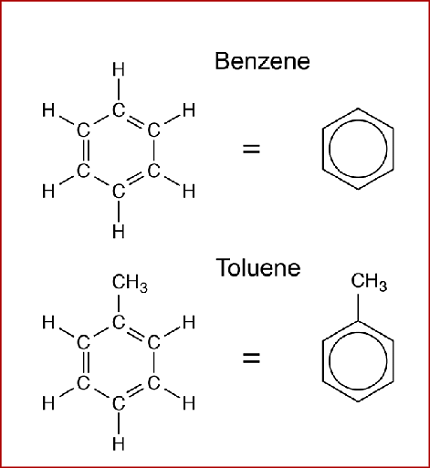

Benzaldehyde is an organic compound with the chemical formula C7H6O. It is an aromatic aldehyde and is derived from the aromatic hydrocarbons toluene or benzene. The nomenclature of benzaldehyde can be broken down as follows:

- The prefix “benz-” indicates that the compound is derived from benzene.

- The suffix “-aldehyde” indicates that the compound has a formyl group (-CHO) attached to an aromatic ring.

Therefore, the name “benzaldehyde” indicates that the compound has a formyl group attached to a benzene ring. When benzaldehyde is derived from toluene, it is sometimes referred to as “tolualdehyde” or “phenylmethanal” because toluene is also known as “methylbenzene” or “phenylmethane”.

The systematic name for benzaldehyde is “benzenecarbaldehyde” or “phenylmethanal” according to IUPAC nomenclature.

Case Study on Benzaldehyde from Toluene and Benzene

Here is a hypothetical case study on the production of benzaldehyde from toluene and benzene:

ABC Chemicals is a manufacturer of fragrances and flavors for the food and beverage industry. One of their main products is a cherry flavoring agent, which contains benzaldehyde as a key ingredient. ABC Chemicals has been sourcing benzaldehyde from an external supplier, but due to rising costs and supply chain disruptions, they are considering producing benzaldehyde in-house.

After conducting a feasibility study and assessing their capabilities, ABC Chemicals decides to produce benzaldehyde from toluene using a multi-step oxidation process. The process involves the following steps:

- Oxidation of Toluene to Benzyl Alcohol: Toluene is first oxidized to benzyl alcohol using potassium permanganate. The reaction is carried out in a reactor under reflux conditions.

- Oxidation of Benzyl Alcohol to Benzaldehyde: Benzyl alcohol is then oxidized to benzaldehyde using chromic acid. The reaction is carried out in a reactor under reflux conditions.

- Purification of Benzaldehyde: The crude benzaldehyde is purified by distillation to obtain a high-purity product.

ABC Chemicals sets up a dedicated production line for benzaldehyde and conducts extensive testing and optimization to achieve high yields and purity levels. They also implement rigorous safety protocols and invest in appropriate equipment and training for their staff.

After several months of production, ABC Chemicals successfully produces high-quality benzaldehyde in-house and is able to reduce costs and improve supply chain reliability for their cherry flavoring product. They also explore other applications for benzaldehyde in their product portfolio and expand their business into new markets.

This case study illustrates how a chemical manufacturer can leverage their expertise and capabilities to produce a key ingredient in-house and improve their business operations. By producing benzaldehyde from toluene, ABC Chemicals was able to reduce costs, improve supply chain reliability, and explore new business opportunities.

White paper on Benzaldehyde from Toluene and Benzene

Here is a white paper on the production of benzaldehyde from toluene and benzene:

Introduction:

Benzaldehyde is an important organic compound that is widely used in the fragrance, flavor, and pharmaceutical industries. It is an aromatic aldehyde that is derived from the aromatic hydrocarbons toluene or benzene. Benzaldehyde has a characteristic almond-like odor and is used as a flavoring agent in foods and beverages, as a fragrance in perfumes and soaps, and as an intermediate in the synthesis of various organic compounds.

Production Methods:

Benzaldehyde can be produced from toluene or benzene using a multi-step oxidation process. The process typically involves the use of strong oxidizing agents such as potassium permanganate or chromic acid, which are capable of oxidizing the aromatic ring to form a formyl group (-CHO) attached to the ring. The process can be summarized as follows:

- Oxidation of Toluene/Benzene to Benzyl Alcohol: Toluene or benzene is first oxidized to benzyl alcohol using an oxidizing agent such as potassium permanganate or chromic acid.

- Oxidation of Benzyl Alcohol to Benzaldehyde: Benzyl alcohol is then oxidized to benzaldehyde using an oxidizing agent such as potassium permanganate or chromic acid.

- Purification of Benzaldehyde: The crude benzaldehyde is purified by distillation to obtain a high-purity product.

The choice of oxidizing agent and the reaction conditions may vary depending on the specific application and the desired yield of benzaldehyde. Other factors such as the choice of solvent, reaction temperature, and reaction time may also influence the yield and purity of the product.

Applications:

Benzaldehyde has a wide range of applications in various industries. It is used as a flavoring agent in foods and beverages, particularly in cherry and almond flavors. It is also used as a fragrance in perfumes, soaps, and other cosmetic products. In addition, benzaldehyde is used as an intermediate in the synthesis of various organic compounds such as dyes, pharmaceuticals, and agrochemicals.

Conclusion:

The production of benzaldehyde from toluene or benzene using a multi-step oxidation process is an important industrial process with wide-ranging applications. The process requires careful handling of strong oxidizing agents and appropriate safety measures. The choice of reaction conditions and purification methods can influence the yield and purity of the product. The applications of benzaldehyde in various industries highlight its importance as a versatile organic compound with unique chemical properties.