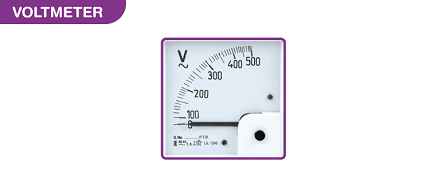

A voltmeter is an instrument used to measure the voltage difference between two points in an electric circuit. It is typically connected in parallel with the component or circuit being measured, and it provides a reading of the voltage across that component or circuit. Voltmeters can be analog or digital and can be designed to measure different ranges of voltage, from millivolts to kilovolts. They are commonly used in electronics, electrical engineering, and physics experiments to measure voltage in a circuit and ensure proper functioning of electrical devices.

What is Voltmeter

A voltmeter is an instrument used to measure the voltage difference between two points in an electric circuit. It measures the potential difference or voltage across a particular component or circuit. Voltmeters are typically connected in parallel with the component or circuit being measured and provide a reading of the voltage across that component or circuit. They can be analog or digital and can be designed to measure different ranges of voltage, from millivolts to kilovolts. Voltmeters are commonly used in electronics, electrical engineering, and physics experiments to measure voltage in a circuit and ensure proper functioning of electrical devices.

Where is Voltmeter

A voltmeter can be located in different places depending on the context. In a laboratory or testing environment, a voltmeter may be part of an electrical testing equipment setup and can be located on a workbench or in a testing station. In a vehicle, a voltmeter may be installed on the dashboard to monitor the voltage of the battery or the electrical system. In industrial settings, voltmeters may be installed on control panels or integrated into machinery to monitor electrical parameters. In general, a voltmeter is typically located near the electrical circuit or component being measured, and it can be a handheld device or permanently installed.

History of Voltmeter

The history of the voltmeter dates back to the 19th century. In 1820, Danish physicist Hans Christian Oersted discovered the phenomenon of electromagnetism, which led to the development of various electrical measuring instruments, including the voltmeter.

One of the earliest designs of the voltmeter was the “electrostatic voltmeter” invented by British scientist William Thomson (also known as Lord Kelvin) in 1855. This device measured voltage by using the electrostatic force generated between two charged plates. In 1884, American electrical engineer Edward Weston developed the first portable and accurate voltmeter, which was based on the principle of moving coil.

In the early 20th century, advancements in electronics and technology led to the development of more advanced voltmeters, including vacuum tube voltmeters and digital voltmeters. In the 1960s and 1970s, solid-state technology was developed, and this led to the development of more compact and accurate digital voltmeters.

Today, voltmeters are an essential tool in electrical engineering, electronics, and physics, and they are used to measure voltage in various applications, ranging from household electrical systems to industrial machinery and electronic devices.

Production of Voltmeter

Voltmeters can be produced using a variety of manufacturing techniques, depending on the type and application of the voltmeter. Here are some general steps that may be involved in the production of a voltmeter:

- Design and prototyping: The design of a voltmeter typically involves selecting appropriate components, such as resistors, capacitors, and transistors, and determining the layout and circuitry needed to measure voltage accurately. A prototype is then created to test the design and identify any issues.

- Manufacturing of components: The individual components of the voltmeter, such as the resistors, capacitors, and transistors, are manufactured separately using a variety of methods, including automated machinery and manual assembly.

- Assembly and testing: The components are then assembled onto a circuit board using automated equipment or by hand. The voltmeter is then tested to ensure that it measures voltage accurately.

- Calibration: Once the voltmeter has been assembled and tested, it may need to be calibrated to ensure that it provides accurate measurements. This may involve adjusting the gain or zero offset of the voltmeter using specialized equipment.

- Final inspection and packaging: The voltmeter is then inspected for defects and packaged for shipping or distribution.

Overall, the production of a voltmeter requires expertise in electrical engineering, circuit design, and manufacturing, and it involves a combination of automated machinery and manual assembly.

Case Study on Voltmeter

Here is an example case study on the use of a voltmeter in an electrical engineering application:

Company X manufactures and sells electronic products, including power supplies, battery chargers, and solar panels. To ensure the quality and reliability of their products, they use voltmeters to measure the voltage of their electrical circuits during production.

In one particular case, Company X was manufacturing a new model of battery charger that was designed to charge multiple types of batteries. During the testing phase, they noticed that some of the chargers were not functioning correctly and were not charging the batteries as expected.

To diagnose the problem, the production team used a voltmeter to measure the voltage across the various components of the charger. They found that the voltage across one of the diodes was lower than expected, indicating that the diode was not functioning correctly.

The production team then replaced the faulty diode, and the charger was tested again. This time, the voltmeter showed that the voltage across the diode was within the expected range, indicating that the diode was now functioning correctly.

Through the use of the voltmeter, the production team was able to identify and diagnose the problem with the battery charger and ensure that the product met the required quality standards. This not only prevented potential failures in the product but also helped the company maintain their reputation for producing high-quality electronic products.

Overall, this case study demonstrates the importance of using voltmeters in electrical engineering applications, as they are essential tools for identifying problems and ensuring the proper functioning of electronic devices.

White paper on Voltmeter

Here is a brief white paper on the voltmeter:

Introduction

The voltmeter is an electronic instrument used to measure voltage in electrical circuits. It is a crucial tool in electrical engineering, electronics, and physics and is used in various applications, ranging from household electrical systems to industrial machinery and electronic devices. This white paper will provide an overview of the voltmeter, its history, types, and uses.

History of the Voltmeter

The history of the voltmeter dates back to the 19th century when Danish physicist Hans Christian Oersted discovered the phenomenon of electromagnetism. This discovery led to the development of various electrical measuring instruments, including the voltmeter. In 1855, British scientist William Thomson (also known as Lord Kelvin) invented the “electrostatic voltmeter,” which measured voltage using the electrostatic force generated between two charged plates. In 1884, American electrical engineer Edward Weston developed the first portable and accurate voltmeter, which was based on the principle of moving coil.

Types of Voltmeters

There are several types of voltmeters, including analog voltmeters, digital voltmeters, and multimeters. Analog voltmeters use a moving pointer or needle to display voltage levels on a calibrated scale. Digital voltmeters, on the other hand, use electronic displays, such as LED or LCD screens, to show voltage levels. Multimeters are versatile instruments that can measure several electrical parameters, including voltage, current, and resistance.

Uses of the Voltmeter

Voltmeters are used in a wide range of applications, including testing and troubleshooting electrical circuits, monitoring battery and power supply voltage levels, and measuring the voltage output of electrical generators and motors. They are also used in research and development to test and measure the performance of electronic devices.

Conclusion

In conclusion, the voltmeter is a critical tool in electrical engineering, electronics, and physics. Its invention has revolutionized the way we measure voltage, and its continued development has led to the creation of more advanced and accurate instruments. As technology advances, the role of the voltmeter will continue to evolve, and it will remain an essential tool for measuring voltage in various applications.