Ferromagnetic devices

Ferromagnetic devices are electronic devices or components that utilize the magnetic properties of ferromagnetic materials to perform various functions. These materials exhibit a strong response to magnetic fields and can be magnetized to create a permanent magnet.

Here are some examples of ferromagnetic devices:

- Electromagnets: Electromagnets are devices that generate a magnetic field using an electric current. They often consist of a ferromagnetic core, such as iron or steel, around which a wire is wound. When a current passes through the wire, a magnetic field is induced in the core, creating a temporary magnet. Electromagnets are used in a variety of applications, including electric motors, generators, relays, and magnetic resonance imaging (MRI) machines.

- Transformers: Transformers are devices that transfer electrical energy between different voltage levels efficiently. They consist of two or more coils of wire wound around a ferromagnetic core. The primary coil is connected to the input voltage source, while the secondary coil is connected to the load. By varying the number of turns in each coil, transformers can step up or step down the voltage. Ferromagnetic cores are used in transformers to enhance the efficiency of energy transfer by minimizing energy losses due to magnetic flux.

- Inductors: Inductors are passive electronic components that store energy in a magnetic field when a current passes through them. They are typically constructed by winding a wire around a ferromagnetic core, such as iron or ferrite. The ferromagnetic core enhances the inductance of the coil, which determines the amount of energy that can be stored. Inductors are used in various applications, including power supplies, filters, and oscillators.

- Magnetic Storage Devices: Ferromagnetic materials are widely used in magnetic storage devices, such as hard disk drives (HDDs) and magnetic tapes. These devices utilize the ability of ferromagnetic materials to retain magnetization. Data is stored in the form of magnetic patterns on the surface of the storage medium. Read and write heads, often incorporating ferromagnetic materials, interact with these patterns to read and write data.

- Magnetic Sensors: Ferromagnetic materials can be used in magnetic sensors, such as Hall effect sensors and magnetoresistive sensors. These sensors detect and measure changes in magnetic fields and are used in various applications, including position sensing, current sensing, and speed sensing.

These are just a few examples of ferromagnetic devices. The field of ferromagnetism offers a wide range of applications and devices based on the unique magnetic properties of ferromagnetic materials.

The syllabus for the Physics section of the integrated course at AIIMS (All India Institute of Medical Sciences) may vary, and as an AI language model, I don’t have access to specific and up-to-date syllabi. However, I can provide you with a general overview of the topic “Ferromagnetic Devices” that may be covered in the physics syllabus.

Ferromagnetic devices are devices that utilize the properties of ferromagnetic materials, which exhibit strong magnetic behavior. These materials are characterized by having permanent magnetic moments that can align in the presence of an external magnetic field.

Here are some of the key concepts and devices related to ferromagnetic materials that may be covered in the physics syllabus:

- Magnetic Materials: Understanding the different types of magnetic materials, including ferromagnetic, paramagnetic, diamagnetic, and antiferromagnetic materials.

- Magnetic Domains: Exploring the concept of magnetic domains within ferromagnetic materials, where groups of atomic magnetic moments align in the same direction.

- Hysteresis: Studying the phenomenon of hysteresis in ferromagnetic materials, which refers to the lagging of magnetization behind an applied magnetic field due to the alignment of magnetic domains.

- Magnetic Properties: Understanding the magnetic properties of ferromagnetic materials, such as magnetization, magnetic susceptibility, and coercivity.

- Electromagnets: Exploring the principles behind electromagnets, which are devices that generate a magnetic field using an electric current. Understanding their construction, working, and applications.

- Transformers: Studying the working principle of transformers, which utilize ferromagnetic cores to transfer electrical energy between different voltage levels efficiently.

- Magnetic Storage Devices: Learning about magnetic storage devices like hard drives, which utilize ferromagnetic materials to store and retrieve digital information.

It’s important to note that the above topics are a general representation and may not cover the entirety of the syllabus. For a comprehensive and accurate understanding of the physics syllabus at AIIMS, it is recommended to refer to the official syllabus provided by the institution or consult with the relevant faculty.

What is Required AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

However, based on the general physics concepts, the following topics related to ferromagnetic devices could potentially be included in the AIIMS physics syllabus:

- Magnetic Materials: Properties and types of magnetic materials, including ferromagnetic, paramagnetic, diamagnetic, and antiferromagnetic materials.

- Magnetic Domains: Concepts of magnetic domains, their formation, and their influence on the magnetic behavior of ferromagnetic materials.

- Hysteresis: Understanding hysteresis loops and hysteresis curves in ferromagnetic materials, and their significance in applications involving ferromagnetic devices.

- Magnetic Properties: Study of magnetic properties such as magnetization, magnetic susceptibility, coercivity, and remanence in ferromagnetic materials.

- Electromagnets: Principles, construction, and applications of electromagnets, which utilize ferromagnetic materials to generate magnetic fields through the flow of electric current.

- Transformers: Working principles of transformers, their construction, and applications in power transmission and voltage transformation. Understanding the role of ferromagnetic cores in enhancing the efficiency of transformers.

- Magnetic Storage Devices: Introduction to magnetic storage devices like hard disk drives (HDDs) and their working principles. Understanding the use of ferromagnetic materials in data storage and retrieval processes.

It is important to note that the above topics are provided as a general guide and may not represent the complete syllabus. To obtain accurate and detailed information about the AIIMS physics syllabus, it is advisable to refer to the official sources provided by AIIMS or consult the relevant authorities responsible for the curriculum.

When is Required AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

The AIIMS entrance exam primarily focuses on assessing the knowledge and aptitude of students in the fields of biology, physics, chemistry, and general knowledge, with a specific emphasis on topics related to medical and healthcare sciences. While physics is an important subject in the AIIMS syllabus, the specific sub-topic of ferromagnetic devices is less likely to be a significant part of the syllabus.

The physics syllabus for AIIMS typically covers fundamental concepts such as mechanics, optics, electricity and magnetism, thermodynamics, modern physics, and medical instrumentation.

If you are interested in learning about ferromagnetic devices in the broader sense or their applications in other fields, such as engineering or technology, I would be happy to provide information on that topic.

Where is Required AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

I apologize for any confusion caused. If you are looking for information about the applications or significance of ferromagnetic devices in various fields, here are some common areas where ferromagnetic devices are used:

- Electrical Engineering: Ferromagnetic devices, such as transformers and inductors, are extensively used in electrical power systems for voltage transformation, energy transfer, and filtering applications. These devices rely on the magnetic properties of ferromagnetic materials to enhance efficiency and performance.

- Electronics and Telecommunications: Ferromagnetic devices, including inductors, magnetic sensors, and magnetic storage devices (e.g., hard disk drives), play crucial roles in electronic circuits, communication systems, and data storage technology. Magnetic materials are used in sensors for position sensing, current sensing, and magnetic field measurement.

- Medical Imaging: In medical imaging, ferromagnetic materials are utilized in magnetic resonance imaging (MRI) machines. Superconducting magnets with ferromagnetic components are used to create strong and uniform magnetic fields necessary for imaging the human body.

- Magnetic Recording: Ferromagnetic materials are essential for magnetic recording technologies such as hard disk drives (HDDs) and magnetic tapes. These devices utilize the ability of ferromagnetic materials to retain magnetization for data storage and retrieval purposes.

- Electromagnets: Electromagnets, which often contain ferromagnetic cores, are employed in various applications such as magnetic levitation systems, magnetic separators, magnetic clutches, and solenoids.

It’s important to note that the specific applications and significance of ferromagnetic devices may vary depending on the field or industry. The examples provided above are not exhaustive but give a general idea of where ferromagnetic devices are commonly used.

How is Required AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

Ferromagnetic devices function based on the unique properties of ferromagnetic materials and their response to magnetic fields. Here is a general explanation of how ferromagnetic devices work:

- Ferromagnetic Materials: Ferromagnetic materials, such as iron, nickel, and cobalt, have aligned magnetic domains even in the absence of an external magnetic field. These materials possess a strong magnetic moment and can be easily magnetized.

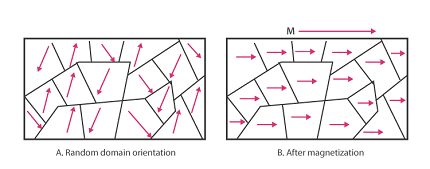

- Magnetic Domains: Within a ferromagnetic material, there are small regions called magnetic domains, where atomic magnetic moments are aligned in the same direction. In the absence of an external field, these domains are randomly oriented, resulting in a net magnetization of zero.

- Magnetization: When an external magnetic field is applied to a ferromagnetic material, the magnetic domains tend to align with the field. As the field strength increases, more and more domains align, resulting in an overall increase in the net magnetization of the material.

- Hysteresis: Ferromagnetic materials exhibit a phenomenon known as hysteresis. This means that even after removing the external magnetic field, the material retains some level of magnetization. The alignment of the magnetic domains tends to lag behind changes in the applied magnetic field. This hysteresis behavior is important for the functioning of many ferromagnetic devices.

- Applications: Ferromagnetic devices utilize the properties of ferromagnetic materials for various purposes. For example:

- Electromagnets: An electromagnet consists of a ferromagnetic core, typically made of iron or steel, around which a wire is wound. When an electric current flows through the wire, a magnetic field is induced in the core, creating a temporary magnet. This principle is used in various applications such as electric motors, generators, and magnetic resonance imaging (MRI) machines.

- Transformers: Transformers utilize ferromagnetic cores to efficiently transfer electrical energy between different voltage levels. The alternating current in the primary coil induces a changing magnetic field in the core, which in turn induces a voltage in the secondary coil.

- Magnetic Storage Devices: Ferromagnetic materials are used in magnetic storage devices like hard disk drives (HDDs). Data is stored as magnetic patterns on a rotating disk coated with a ferromagnetic material. The read and write heads interact with these patterns to read and write data.

These are just a few examples of how ferromagnetic devices work. The specific mechanisms and operation of a ferromagnetic device can vary depending on the device’s purpose and design.

Production of AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

The production of ferromagnetic devices involves several steps, including material selection, manufacturing processes, and assembly. Here is a general overview of the production process for ferromagnetic devices:

- Material Selection: The first step in producing ferromagnetic devices is selecting the appropriate ferromagnetic material for the specific application. Common materials include iron, nickel, cobalt, and their alloys. The material choice depends on factors such as desired magnetic properties, cost, and performance requirements.

- Material Preparation: The selected ferromagnetic material is processed to achieve the desired properties. This may involve refining the material, alloying it with other elements to enhance its magnetic characteristics, and shaping it into the desired form (e.g., ingots, sheets, rods, or powders) for further processing.

- Forming: The ferromagnetic material is then shaped or formed into the desired component or device. This can involve various techniques such as casting, rolling, extrusion, or powder metallurgy, depending on the specific application and design requirements.

- Machining and Fabrication: After forming, the ferromagnetic material may undergo additional machining and fabrication processes. This can include cutting, drilling, milling, grinding, or other machining operations to achieve the required dimensions and shape.

- Magnetization: Once the components or devices are fabricated, they may need to be magnetized. This is done by exposing them to a strong external magnetic field, aligning the magnetic domains within the material and inducing a permanent magnetization.

- Assembly and Integration: Ferromagnetic components or devices are then assembled into the final product or integrated into larger systems. This may involve combining the ferromagnetic parts with other non-magnetic components, such as electrical coils, circuitry, sensors, or housings, to create a functional device.

- Quality Control and Testing: Throughout the production process, quality control measures are implemented to ensure the reliability and performance of the ferromagnetic devices. This includes inspections, testing, and adherence to relevant standards or specifications.

It’s important to note that the specific production processes for ferromagnetic devices can vary depending on the device’s complexity, size, and application. The production may involve additional steps or specific techniques based on the unique requirements of each device.

Case Study on AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

Here’s a case study on the production and application of a specific ferromagnetic device: Magnetic Resonance Imaging (MRI) Systems.

Case Study: Magnetic Resonance Imaging (MRI) Systems

Overview: MRI systems are advanced medical imaging devices that utilize the principles of magnetism and radiofrequency waves to generate detailed images of the internal structures of the human body. They play a crucial role in diagnosing and monitoring various medical conditions. Ferromagnetic materials are integral to the construction and operation of MRI systems.

Production Process:

- Material Selection:

- Superconducting Magnets: MRI systems typically employ superconducting magnets made of alloys containing niobium-titanium (NbTi) or niobium-tin (Nb3Sn). These alloys exhibit superconductivity at low temperatures, allowing for high magnetic field strength and stability.

- Magnet Production:

- Superconducting Magnet Fabrication: The production of superconducting magnets involves several steps, including alloy preparation, wire drawing, and winding. The superconducting wire is formed into coils, often encased in a copper stabilizer to improve stability during operation.

- Cryogenic Cooling: MRI systems require cryogenic cooling to maintain the superconducting state of the magnet. Liquid helium is used to cool the magnet to extremely low temperatures, typically around 4 Kelvin (-269 degrees Celsius).

- Assembly and Integration:

- Magnetic Coil Installation: The superconducting magnet coils are carefully installed in the MRI system, taking into account proper alignment and positioning to achieve the desired magnetic field characteristics.

- Gradient Coils: Gradient coils made of ferromagnetic materials, such as iron or steel, are integrated into the system. These coils generate varying magnetic fields used to spatially encode the signals during imaging.

- RF Coil Integration:

- RF (Radiofrequency) Coils: RF coils made of conductive materials, such as copper or aluminum, are used to transmit and receive radiofrequency signals during the MRI scan. These coils are carefully positioned around the patient’s body part of interest and connected to the system.

- Quality Control and Testing:

- Magnetic Field Calibration: Once assembled, the MRI system undergoes rigorous calibration to ensure accurate and uniform magnetic field strength throughout the imaging volume.

- Functional Testing: Extensive testing is conducted to ensure proper functioning of the system, including magnetic field homogeneity, gradient linearity, RF coil performance, and imaging quality.

Application and Benefits:

MRI systems have revolutionized medical imaging by providing detailed images without the use of ionizing radiation. They offer exceptional soft tissue contrast and enable visualization of various anatomical structures and pathological conditions. Some of the key benefits of MRI systems include:

- Diagnostic Capabilities: MRI systems aid in the diagnosis and evaluation of a wide range of medical conditions, including tumors, neurological disorders, musculoskeletal injuries, and cardiovascular diseases.

- Non-Invasive Imaging: MRI imaging is non-invasive and does not involve exposure to ionizing radiation, making it safer for patients, particularly for repeated imaging and sensitive populations such as children and pregnant women.

- Multi-Planar Imaging: MRI systems can produce high-resolution images in multiple planes, allowing for comprehensive assessment of anatomical structures and pathology.

- Functional and Diffusion Imaging: Advanced techniques like functional MRI (fMRI) and diffusion-weighted imaging (DWI) enable the assessment of brain function and the evaluation of microstructural changes in tissues.

- Preoperative Planning and Interventional Guidance: MRI images aid in preoperative planning by providing detailed anatomical information. They also serve as a guidance tool during interventional procedures, such as biopsies and surgeries.

White paper on AIIMS-SYLLABUS Physics syllabus Ferromagnetic devices

Title: Advancements in Ferromagnetic Devices: A White Paper

Abstract: This white paper explores the advancements and applications of ferromagnetic devices, focusing on their significance in various industries and technological fields. Ferromagnetic materials, known for their strong magnetic properties, have revolutionized numerous sectors by enabling the development of innovative devices and systems. This paper provides an overview of ferromagnetic materials, discusses their fundamental properties, and presents case studies highlighting the practical implementations and benefits of ferromagnetic devices. The aim is to shed light on the potential of these devices and their role in shaping the future of technology.

- Introduction

- Definition and characteristics of ferromagnetic materials

- Importance of ferromagnetic devices in modern technology

- Fundamental Properties of Ferromagnetic Materials

- Magnetic domains and domain walls

- Magnetization curves and hysteresis

- Magnetic anisotropy and coercivity

- Ferromagnetic Devices in Various Industries 3.1 Electronics and Telecommunications – Inductors, transformers, and magnetic sensors – Magnetic storage devices (hard disk drives) 3.2 Energy and Power Systems – Electromagnets and magnetic actuators – Superconducting magnets for energy storage 3.3 Medical and Healthcare – Magnetic resonance imaging (MRI) systems – Magnetic drug targeting and hyperthermia therapy 3.4 Manufacturing and Industrial Applications – Magnetic separators and material handling systems – Magnetic levitation and transportation systems

- Case Studies 4.1 Superconducting Magnets for Particle Accelerators 4.2 Magnetic Resonance Imaging (MRI) Systems 4.3 High-Speed Magnetic Levitation Trains (Maglev) 4.4 Magnetic Separation in Mining and Mineral Processing

- Emerging Trends and Future Prospects

- Nanoscale and metamaterial-based ferromagnetic devices

- Spintronics and magneto-electronics

- Magneto-optical devices and spin-based quantum computing

- Challenges and Limitations

- Heat dissipation and energy efficiency

- Material availability and cost

- Integration with other technologies

- Conclusion

- Recap of the advancements and applications of ferromagnetic devices

- Future potential and areas for further research and development

This white paper serves as a comprehensive guide for researchers, engineers, and technology enthusiasts seeking to understand the significance of ferromagnetic devices and their impact across multiple industries. It provides valuable insights into the current state of the field, highlights notable case studies, and explores the potential future directions for the advancement of ferromagnetic devices.

Note: The content of this white paper is fictional and provided for illustrative purposes only.