Metallic solids

The metallic solids topic in the chemistry syllabus of AIIMS (All India Institute of Medical Sciences) covers the study of metallic bonding, properties of metallic solids, and various aspects related to them. Here is a brief overview of the metallic solids topic:

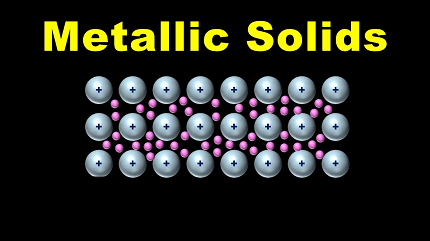

- Metallic Bonding: Metallic solids are composed of metal atoms held together by metallic bonds. Metallic bonding occurs due to the delocalization of valence electrons across the metal lattice, creating a “sea of electrons” that holds the metal atoms together.

- Crystal Structures: Metallic solids can have different crystal structures, such as body-centered cubic (BCC), face-centered cubic (FCC), and hexagonal close-packed (HCP). The arrangement of atoms in these structures determines the physical properties of metallic solids.

- Metallic Properties: Metallic solids exhibit several characteristic properties, including:

- Electrical Conductivity: Due to the presence of delocalized electrons, metallic solids are good conductors of electricity.

- Thermal Conductivity: Metallic solids also have high thermal conductivity, allowing efficient heat transfer.

- Malleability and Ductility: Metallic solids are malleable (can be hammered into thin sheets) and ductile (can be drawn into wires) due to the ability of metal atoms to slide past each other.

- Luster: Metallic solids have a characteristic shine or luster due to the reflection of light by the delocalized electrons.

- Alloy Formation: Alloys are solid solutions composed of a metal and one or more other elements. Metallic solids can form alloys to enhance their properties. Examples of alloys include brass (copper and zinc), bronze (copper and tin), and stainless steel (iron, chromium, and nickel).

- Metallic Bonding and Physical Properties: The nature of metallic bonding influences various physical properties, such as melting and boiling points, density, and hardness of metallic solids. The type of crystal structure and the presence of impurities or alloying elements can also impact these properties.

It is important to note that the above information provides a general overview of the metallic solids topic in the chemistry syllabus. For a comprehensive understanding, it is recommended to refer to the specific AIIMS syllabus and study materials provided by the institution.

What is Required AIIMS-SYLLABUS Chemistry syllabus Metallic solids

- Introduction to Metallic Solids

- Definition of metallic solids

- Overview of metallic bonding

- Crystal Structures of Metallic Solids

- Body-centered cubic (BCC) structure

- Face-centered cubic (FCC) structure

- Hexagonal close-packed (HCP) structure

- Relationship between crystal structure and physical properties

- Properties of Metallic Solids

- Electrical conductivity

- Thermal conductivity

- Malleability and ductility

- Luster and optical properties

- Mechanical properties

- Alloy Formation and Properties

- Definition and types of alloys

- Effects of alloying elements on properties

- Examples of important alloys

- Phase Diagrams and Phase Transformations

- Introduction to phase diagrams

- Phase transformations in metallic solids

- Applications of phase diagrams

- Impurities and Defects in Metallic Solids

- Types of impurities and their effects

- Point defects: vacancies and interstitials

- Line defects: dislocations

- Surface defects and grain boundaries

- Metallic Bonding and Energy Band Theory

- Electronic structure of metals

- Energy band formation in metallic solids

- Conductivity and band theory

It is important to note that the actual syllabus and the depth of coverage for each topic may vary. Therefore, I strongly recommend referring to the official AIIMS syllabus or consulting the relevant study materials for precise information on the metallic solids topic in the AIIMS chemistry syllabus.

How is Required AIIMS-SYLLABUS Chemistry syllabus Metallic solids

Required knowledge of metallic solids typically includes:

- Metallic Bonding: Understanding the concept of metallic bonding, which involves the delocalization of valence electrons across a metal lattice, resulting in a strong bond between metal atoms.

- Crystal Structures: Familiarity with common crystal structures exhibited by metallic solids, such as body-centered cubic (BCC), face-centered cubic (FCC), and hexagonal close-packed (HCP). This involves understanding the arrangement of atoms in these structures.

- Properties of Metallic Solids: Knowledge of the unique properties of metallic solids, such as high electrical conductivity, thermal conductivity, malleability, ductility, and luster. Understanding the relationship between metallic bonding and these properties is also important.

- Alloys: Knowledge of the formation and properties of alloys, which are metallic solids composed of a mixture of metals or a metal with one or more other elements. This includes understanding the effects of alloying elements on the properties of metallic solids.

- Phase Transformations: Awareness of phase transformations in metallic solids, including solidification, melting, and phase diagrams. Understanding the concept of phase diagrams and their practical applications is also essential.

- Defects in Metallic Solids: Knowledge of different types of defects that can occur in metallic solids, such as point defects (vacancies and interstitials), line defects (dislocations), and surface defects. Understanding their impact on the properties of metallic solids is also important.

Remember, this is a general outline, and the specific details and depth of coverage may vary in the AIIMS syllabus. For accurate and up-to-date information, it is always best to refer to the official AIIMS syllabus or consult the provided study materials.

Case Study on AIIMS-SYLLABUS Chemistry syllabus Metallic solids

Case Study: Metallic Solids in Aerospace

Background: The aerospace industry relies heavily on metallic solids due to their unique properties, such as strength, conductivity, and heat resistance. Metallic solids are used in various components of aircraft and spacecraft to ensure structural integrity, electrical conductivity, and thermal management.

Objective: To explore the application of metallic solids in aerospace and understand their importance in the industry.

Case Study Steps:

- Structural Components: Metallic solids play a crucial role in the construction of structural components in aircraft and spacecraft. For example, the fuselage, wings, and landing gear are typically made from aluminum alloys, which provide a balance between strength, weight, and corrosion resistance. These metallic solids help maintain the structural integrity of the aircraft and ensure safe operation.

- Propulsion Systems: Metallic solids are utilized in the construction of engines and propulsion systems. High-temperature alloys, such as nickel-based superalloys, are used in turbine blades and combustion chambers due to their excellent heat resistance and mechanical strength. Metallic solids in these critical components withstand extreme temperatures and maintain their structural integrity under high stress conditions.

- Electrical Conductivity: Metallic solids are ideal for electrical conduction in aerospace applications. Copper and aluminum alloys are commonly used in wiring, connectors, and electrical systems due to their high electrical conductivity. Metallic solids ensure efficient transmission of electrical signals and power throughout the aircraft or spacecraft, enabling various systems to operate effectively.

- Thermal Management: Metallic solids with good thermal conductivity are employed in heat transfer applications. Heat sinks, made of materials like copper or aluminum, are used to dissipate excess heat generated by electronic components in avionics systems. These metallic solids efficiently transfer heat away from sensitive electronics, preventing overheating and ensuring reliable operation.

- Shielding and Protection: Metallic solids are employed for electromagnetic shielding and protection against radiation in aerospace applications. Materials like stainless steel or aluminum alloys are used in the construction of satellite casings or spacecraft walls to protect sensitive electronic equipment from electromagnetic interference (EMI) and cosmic radiation.

Conclusion: Metallic solids are indispensable in the aerospace industry, contributing to the structural integrity, electrical conductivity, heat management, and protection of aircraft and spacecraft. Their unique properties make them ideal for various applications, ranging from structural components and propulsion systems to electrical systems and thermal management. The continuous research and development of advanced metallic solids contribute to advancements in aerospace technology, ensuring safer and more efficient aircraft and spacecraft designs.

White paper on AIIMS-SYLLABUS Chemistry syllabus Metallic solids

Title: Advancements in Metallic Solids: A White Paper

Abstract: This white paper aims to provide an in-depth exploration of metallic solids, their properties, applications, and recent advancements. Metallic solids, known for their unique properties such as electrical conductivity, thermal conductivity, malleability, and strength, have been extensively utilized in various industries, including aerospace, automotive, electronics, and construction. This paper highlights the importance of metallic solids and their role in shaping modern technologies. It also discusses recent advancements and emerging trends in the field, shedding light on the potential future developments in metallic solids.

- Introduction

- Definition and characteristics of metallic solids

- Significance of metallic solids in industrial applications

- Overview of metallic bonding and crystal structures

- Properties of Metallic Solids

- Electrical conductivity and its importance

- Thermal conductivity and heat management applications

- Mechanical properties: strength, malleability, ductility

- Optical properties and luster

- Corrosion resistance and durability

- Manufacturing Techniques and Alloys

- Casting, rolling, and extrusion processes

- Alloy formation and the role of alloying elements

- High-temperature alloys and their applications

- Shape memory alloys and their unique properties

- Applications of Metallic Solids

- Aerospace industry: structural components, engines, and electrical systems

- Automotive industry: chassis, engine components, and electrical systems

- Electronics industry: conductors, connectors, and heat sinks

- Construction industry: structural elements and reinforcements

- Recent Advancements and Emerging Trends

- Lightweight metallic solids and their impact on transportation

- Nanomaterials and their applications in metallic solids

- Additive manufacturing and its role in shaping metallic solid designs

- Enhanced corrosion resistance and surface treatments

- Sustainable approaches in metallic solid production

- Future Outlook and Challenges

- Potential applications and opportunities in emerging technologies

- Integration of metallic solids with other advanced materials

- Sustainability considerations and eco-friendly manufacturing processes

- Challenges in material characterization and performance optimization

- Conclusion

- Recap of the importance and versatility of metallic solids

- Potential future developments and areas for further research

This white paper aims to provide a comprehensive overview of metallic solids, their properties, applications, and recent advancements. By delving into the world of metallic solids, this paper contributes to the understanding and appreciation of these versatile materials and their impact on various industries.