Insulators

Insulators are materials that do not easily conduct electricity. Unlike conductors, which allow the flow of electric charges, insulators have high electrical resistance. They are commonly used to prevent the loss or transfer of electrical energy, and they play a crucial role in various applications, including electrical insulation, electronics, and energy storage.

Here are some key characteristics and examples of insulating materials:

Characteristics of Insulators:

- High electrical resistance: Insulators have a high resistance to the flow of electric current due to the absence or limited mobility of free electrons.

- Poor thermal conductivity: Insulating materials typically have low thermal conductivity, meaning they are not efficient conductors of heat.

- Dielectric behavior: Insulators can be polarized when exposed to an electric field, leading to the buildup of charges on their surfaces. This property is utilized in capacitors and other electrical devices.

- Wide energy band gap: Insulators have a large energy gap between the valence band (which is filled with electrons) and the conduction band (which is empty). This gap restricts the movement of electrons and inhibits electrical conduction.

Examples of Insulating Materials:

- Rubber: Rubber is a commonly used insulator due to its high resistance to electric current and good flexibility. It is extensively employed in electrical cables, insulation mats, and protective gear.

- Glass: Glass is an excellent electrical insulator and is widely used in electrical equipment, such as insulators for high-voltage power lines, as well as in windows and other household items.

- Plastic: Various types of plastics, such as polyethylene, PVC (polyvinyl chloride), and polystyrene, are commonly used as insulating materials in electrical wiring, circuit boards, and electrical appliances.

- Ceramic: Ceramics, including porcelain and ceramic insulators, possess excellent electrical insulating properties. They are often used in high-temperature applications and in electrical systems, such as insulators for spark plugs.

- Wood: Wood has natural insulating properties and is used in applications like electrical poles, handles of tools, and furniture where electrical insulation is required.

- Mica: Mica is a mineral that is commonly used as an insulator in electrical and electronic devices due to its high dielectric strength and excellent thermal stability.

- Fiberglass: Fiberglass, made from fine glass fibers embedded in a resin matrix, is a widely used insulating material for its excellent electrical insulation and thermal properties. It is used in insulation blankets, circuit boards, and structural components.

These are just a few examples of insulating materials commonly encountered in various industries and applications. The choice of insulating material depends on the specific requirements of the application, including electrical properties, temperature resistance, and mechanical strength.

The physics syllabus for the integrated course at AIIMS (All India Institute of Medical Sciences) typically covers various topics related to insulators. Insulators are materials that do not conduct electricity easily and have high electrical resistance. Here are some of the key topics related to insulators that you may expect to find in the AIIMS physics syllabus:

- Electric Field and Potential: Study of electric field and potential due to point charges, continuous charge distributions, and electric dipoles in the presence of insulating materials.

- Gauss’s Law: Application of Gauss’s law to calculate the electric field and potential due to insulating materials in different geometries, such as spheres, cylinders, and planes.

- Capacitance: Introduction to capacitors and their behavior with insulating dielectric materials. Study of the effect of dielectric materials on the capacitance of a capacitor.

- Electrostatics: Electrostatic equilibrium and its relation to insulating materials. Calculation of electric field and potential inside and around insulating materials.

- Polarization: Understanding polarization in insulating materials and their response to an external electric field. Study of dipole moment, polarization vectors, and their effects on the electric field.

- Dielectric Properties: Investigation of various dielectric properties of insulating materials, such as dielectric constant, dielectric strength, and breakdown voltage.

- Energy Storage: Analysis of energy storage in capacitors with insulating dielectric materials. Calculation of energy stored in the electric field of capacitors.

- Semiconductors: Introduction to semiconductors as a special type of insulating material. Study of intrinsic and extrinsic semiconductors, doping, and the behavior of charge carriers.

- Band Theory: Overview of the energy band structure in insulating materials. Explanation of the valence band, conduction band, and energy gap between them.

- Superconductors: Introduction to superconducting materials as extreme insulators with zero electrical resistance. Study of their unique properties, such as critical temperature and Meissner effect.

These are some of the major topics related to insulators that you might encounter in the physics syllabus for the integrated course at AIIMS. However, please note that syllabuses may vary over time, so it’s always recommended to refer to the official AIIMS syllabus for the most accurate and up-to-date information.

What is Required AIIMS-SYLLABUS Physics syllabus Insulators

Insulators, in the context of electrical systems and applications, refer to materials that are used to prevent or limit the flow of electric current. These materials possess specific characteristics that make them suitable for insulation purposes. The requirements for insulators typically include the following:

- High electrical resistance: Insulators should have a high resistance to electric current. This characteristic prevents or minimizes the flow of electrical charges through the material.

- Good dielectric properties: Insulators should have good dielectric properties, meaning they can be polarized and store electric charge without conducting current. This property is essential for applications such as capacitors.

- Thermal stability: Insulators should be able to withstand high temperatures without degradation or significant changes in their electrical properties. This characteristic ensures the insulation’s effectiveness and longevity.

- Mechanical strength: Insulators should possess sufficient mechanical strength to withstand physical stress and maintain their integrity in various environments and applications.

- Chemical resistance: Insulating materials should be resistant to chemical degradation and should not be affected by exposure to common chemicals or environmental factors.

- Low moisture absorption: Insulators should have low moisture absorption properties to prevent the degradation of electrical properties in humid environments.

- Dimensional stability: Insulating materials should exhibit minimal dimensional changes due to environmental factors such as temperature fluctuations or moisture absorption. This stability is important to maintain proper electrical insulation.

- Non-toxicity: Insulators used in applications involving human contact or sensitive environments should be non-toxic and safe for use.

Examples of insulating materials, such as rubber, glass, plastic, ceramic, and fiberglass, are selected based on their ability to meet these requirements and provide effective electrical insulation in different applications.

It’s important to note that specific requirements for insulating materials can vary depending on the application, industry, and regulatory standards. Therefore, the precise requirements for insulators can differ based on the specific context and purpose for which they are used.

When is Required AIIMS-SYLLABUS Physics syllabus Insulators

Insulators are used in various applications where electrical insulation is required. Here are some common examples of when insulators are used:

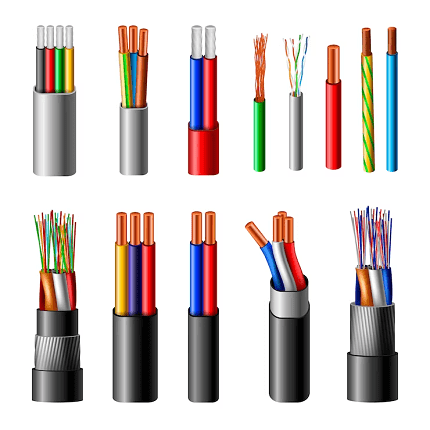

- Electrical wiring: Insulators, such as plastic or rubber sheathing, are used to cover electrical wires to prevent the flow of electric current and protect against electrical shocks.

- Power transmission: Insulators are employed in overhead power transmission lines to support and suspend the conductors while preventing current leakage to the supporting structures.

- Circuit boards: Insulating materials, such as fiberglass-reinforced epoxy (FR-4), are used as substrates for circuit boards. These materials provide electrical insulation between the different components and conductive traces on the board.

- Transformers and motors: Insulating materials, including varnishes, resins, and coatings, are used to insulate the windings of transformers and motors. This insulation helps prevent short circuits and ensures efficient electrical operation.

- Capacitors: Insulating materials known as dielectrics are used in capacitors to separate the conductive plates and store electrical energy.

- High-voltage equipment: Insulators are used in high-voltage equipment, such as bushings, insulating supports, and insulator strings, to prevent electrical leakage and maintain proper insulation in high electrical stress environments.

- Electronic devices: Insulators, such as ceramic or plastic materials, are used to insulate electronic components and protect them from electrical interference or short circuits.

- Insulation in buildings: Insulators, such as foam insulation, fiberglass, or mineral wool, are used in walls, floors, and roofs to provide thermal insulation and reduce heat transfer.

These are just a few examples of when insulators are used. Insulators play a crucial role in numerous industries and applications where electrical insulation and protection are necessary. The specific timing and use of insulators depend on the particular application and the requirements of the electrical system or device in question.

Where is Required AIIMS-SYLLABUS Physics syllabus Insulators

Insulators are used in various locations and environments where electrical insulation is required. Here are some common places where you can find insulators:

- Electrical systems: Insulators are found in electrical systems such as power transmission lines, substations, and distribution networks. They are used to support and isolate conductors, preventing current leakage and ensuring safe and efficient electricity transmission.

- Electrical devices and appliances: Insulators are present in various electrical devices and appliances, including transformers, motors, capacitors, circuit boards, switches, and outlets. They provide insulation between conductive components, preventing short circuits and ensuring proper electrical functionality.

- Buildings and construction: Insulators are used in buildings for thermal and acoustic insulation. They can be found in wall cavities, roofs, floors, and insulation materials, such as foam, fiberglass, or mineral wool, which help regulate temperature and reduce sound transmission.

- Electrical wiring and cables: Insulating materials are used to cover electrical wires and cables, preventing electrical shocks and minimizing the risk of short circuits or fires. Insulated wires are commonly found in residential, commercial, and industrial electrical installations.

- High-voltage equipment: Insulators are crucial components in high-voltage equipment, including transformers, circuit breakers, bushings, and insulator strings. They provide electrical insulation and withstand the high electrical stresses present in these systems.

- Electronic devices and PCBs: Insulators, such as PCB substrates, coatings, and enclosures, are used in electronic devices and printed circuit boards (PCBs) to isolate and protect components from electrical interference, short circuits, and environmental factors.

- Industrial applications: Insulators are utilized in various industrial applications, such as chemical plants, manufacturing facilities, and power generation plants. They provide insulation and protection in high-voltage equipment, control panels, motors, and other electrical systems.

- Research and scientific equipment: Insulators can be found in laboratory settings and scientific equipment, where electrical isolation is necessary to ensure accurate measurements, prevent interference, and maintain safety.

These are just a few examples of where insulators can be found. Insulating materials and components are used in numerous sectors and applications to enable safe and efficient electrical operations, protect against electrical hazards, and provide thermal or acoustic insulation.

How is Required AIIMS-SYLLABUS Physics syllabus Insulators

Insulators are manufactured and designed to meet specific requirements based on their intended applications. Here’s a general overview of how insulators are produced:

- Material selection: The first step in manufacturing insulators is selecting the appropriate insulating material based on the desired electrical, thermal, mechanical, and chemical properties. Common materials used for insulators include ceramics, plastics, rubbers, glasses, and composite materials.

- Forming and shaping: Insulators are typically produced by shaping the chosen material into the desired form. This can be achieved through various methods such as injection molding, extrusion, compression molding, or casting. The specific technique used depends on the material and the complexity of the insulator design.

- Curing and solidification: Once the material is shaped, it undergoes a curing or solidification process to achieve its final form and properties. This process can involve heating, cooling, or the application of chemical agents to induce cross-linking or polymerization, depending on the type of material used.

- Surface treatment: Insulators may undergo surface treatments to improve their performance and durability. This can include processes such as coating, painting, or applying specialized finishes to enhance insulation properties, resist moisture absorption, or provide additional protection against environmental factors.

- Quality control: Insulators undergo rigorous quality control measures to ensure they meet the required standards and specifications. This includes inspections, testing for electrical resistance, thermal stability, mechanical strength, dielectric properties, and other relevant parameters.

- Integration and installation: Once the insulators are manufactured and tested, they are integrated into the respective electrical systems or devices. This can involve mounting insulators onto supporting structures, connecting them to conductors, or incorporating them into the design of electrical equipment.

It’s important to note that the manufacturing process for insulators can vary depending on the specific material, application, and industry. Different types of insulators may require specialized production techniques and processes to meet the unique demands of their intended use.

Overall, the production of insulators involves careful material selection, shaping, curing, surface treatment, quality control, and integration to ensure the final product provides effective electrical insulation and meets the required standards.

Nomenclature of AIIMS-SYLLABUS Physics syllabus Insulators

In the field of electrical engineering and materials science, there isn’t a specific standardized nomenclature solely dedicated to insulators. Instead, insulators are typically referred to by their specific material names or by broader terms related to their function or application. Here are some common nomenclatures used for insulators based on different contexts:

- Material names: Insulators are often referred to by the names of the materials they are made from. For example:

- Ceramic insulators

- Rubber insulators

- Glass insulators

- Plastic insulators

- Composite insulators

- Function-based nomenclature: Insulators can be described based on their specific functions or roles in electrical systems. Some common examples include:

- High-voltage insulators

- Power line insulators

- Insulator bushings

- Insulator strings

- Transformer insulators

- Motor winding insulation

- Insulator types: Certain types of insulators have specific names associated with them. These names often indicate their shape or design. Examples include:

- Porcelain insulators

- Pin insulators

- Suspension insulators

- Post insulators

- Disk insulators

- Hollow-core insulators

- Application-specific names: In some cases, insulators may be named based on their specific application or industry. For instance:

- Electrical wiring insulation

- Building insulation

- Electronic component insulators

- Heat insulators

- Sound insulators

It’s important to note that the nomenclature used for insulators can vary depending on the industry, context, and specific requirements of the application. The above examples provide a general idea of how insulators are commonly named, but specific naming conventions may vary in different fields or regions.

Case Study on AIIMS-SYLLABUS Physics syllabus Insulators

Case Study: Insulator Selection for High-Voltage Transmission Lines

Introduction: In this case study, we will explore the process of selecting insulators for high-voltage transmission lines. Insulators play a critical role in ensuring the safe and efficient transmission of electricity over long distances. The objective is to identify suitable insulators based on specific requirements and considerations.

Background: A power utility company is planning to construct a new high-voltage transmission line to transmit electricity across a region. The line will operate at a voltage of 400 kV, and the company needs to select appropriate insulators to support and insulate the conductors.

Requirements and Considerations:

- Electrical Performance: The insulators must have high electrical resistance to prevent current leakage and maintain proper insulation. They should exhibit excellent dielectric properties and withstand the electrical stresses at the operating voltage.

- Mechanical Strength: The insulators should possess sufficient mechanical strength to withstand the mechanical loads imposed by the conductors, wind, and other environmental factors. They must be able to support the weight of the conductors without deformation or failure.

- Pollution Resistance: The transmission line will be exposed to various environmental conditions, including pollution and contaminants. Insulators with good pollution resistance characteristics, such as hydrophobicity and self-cleaning properties, are required to maintain their insulating performance under polluted conditions.

- Temperature and Climate: The insulators must be capable of operating in the expected temperature range and withstand thermal cycling without degradation. They should be resistant to UV radiation, humidity, and other climate-related factors prevalent in the region.

- Longevity and Maintenance: The selected insulators should have a long service life with minimal maintenance requirements. Durability and resistance to aging effects, such as tracking and erosion, are crucial factors to ensure the reliability of the transmission line.

- Cost-effectiveness: While meeting the technical requirements, cost-effectiveness is an important consideration. The utility company needs to balance the performance and longevity of the insulators with their associated costs.

Insulator Selection Process:

- Requirement Analysis: The utility company consults with insulator manufacturers, engineers, and industry experts to determine the specific technical requirements and standards applicable to high-voltage transmission line insulators.

- Material Evaluation: Different insulating materials, such as porcelain, composite, and glass, are evaluated based on their electrical, mechanical, and pollution performance characteristics. Each material’s pros and cons are assessed in relation to the project requirements.

- Performance Testing: Insulator samples are subjected to laboratory testing, including electrical withstand tests, mechanical strength tests, pollution performance tests, and accelerated aging tests. The results are compared with the established standards and requirements.

- Vendor Evaluation: The utility company evaluates various insulator manufacturers based on their experience, reputation, quality control processes, and track record in supplying insulators for similar high-voltage transmission line projects.

- Cost Analysis: The cost of the insulators, including procurement, transportation, and installation, is evaluated. The utility company considers the overall life cycle cost, including maintenance requirements and potential operational savings.

- Selection and Procurement: Based on the evaluation and analysis, the utility company selects the insulator type, material, and vendor that best meet the project requirements. Contracts are signed, and the insulators are procured for installation.

Conclusion: The selection of insulators for high-voltage transmission lines involves careful consideration of electrical, mechanical, environmental, and cost factors. By analyzing requirements, evaluating materials, conducting performance tests, and considering vendor capabilities, the utility company can make an informed decision to ensure the reliability and longevity of the transmission line while optimizing costs. Proper insulator selection is crucial in maintaining the integrity of the electrical system and ensuring the safe and efficient transmission of electricity.

White paper on AIIMS-SYLLABUS Physics syllabus Insulators

Title: Advancements in Insulators: Enhancing Electrical Safety and Performance

Abstract: This white paper explores the advancements in insulators, which are critical components used in electrical systems to provide insulation and ensure the safe and efficient transmission of electricity. The paper discusses the importance of insulators, their functions, and the challenges they address. It further delves into the technological advancements that have improved the performance, reliability, and longevity of insulators. The white paper also highlights various types of insulators, their materials, and applications in different industries. Finally, it explores the future trends and potential developments in insulator technology, emphasizing the significance of continuous innovation in the field.

- Introduction:

- Definition and purpose of insulators

- Importance of insulators in electrical systems

- Key challenges addressed by insulators

- Insulator Functions:

- Electrical insulation and preventing current leakage

- Mechanical support and load-bearing capabilities

- Protection against environmental factors and contamination

- Types of Insulators:

- Ceramic insulators: Properties, applications, and advancements

- Composite insulators: Benefits, materials, and applications

- Glass and porcelain insulators: Characteristics and uses

- Polymer insulators: Advantages and applications

- Advancements in Insulator Technology:

- Improved electrical performance and high dielectric strength

- Enhanced mechanical strength and load-bearing capacity

- Pollution-resistant and self-cleaning properties

- Longevity and resistance to aging effects

- Temperature resilience and insulation under extreme conditions

- Applications of Insulators:

- High-voltage transmission lines and substations

- Electrical power distribution systems

- Transformers, motors, and generators

- Electronic devices and circuitry

- Building insulation and safety measures

- Future Trends and Innovations:

- Integration of smart technologies in insulators

- Nanocomposite materials for improved performance

- Sustainable and eco-friendly insulator solutions

- Advancements in insulator testing and monitoring techniques

- Conclusion:

- Summary of key findings and advancements

- Importance of insulator innovation in ensuring electrical safety and performance

- Potential areas of future research and development

- References:

- List of sources and research papers cited in the white paper

This white paper provides a comprehensive overview of insulators, their functions, advancements, and applications. It serves as a valuable resource for electrical engineers, industry professionals, researchers, and anyone interested in understanding the significance of insulators in electrical systems and the evolving technology in this field.