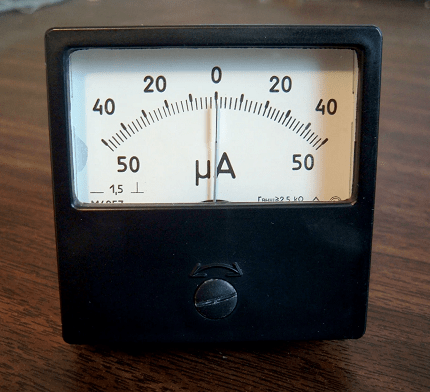

An ammeter is an instrument used to measure the electric current in a circuit. It is typically connected in series with the circuit so that all of the current flows through it. The ammeter measures the flow of electrical charge in amperes (A) and is usually calibrated in milliamperes (mA) or microamperes (μA) for smaller currents.

The ammeter has a very low resistance, so it does not significantly affect the circuit it is measuring. It usually has a needle or digital display that indicates the amount of current flowing through the circuit. It is important to use the correct range on the ammeter when taking a measurement, as too much current can damage the instrument or cause inaccurate readings.

Ammeters are commonly used in electrical and electronic experiments, as well as in industrial settings to monitor the current flowing through machinery and other equipment.

What is Required General Ammeter

A general ammeter is a device that can measure a range of electric currents. The requirements for a general ammeter include:

- Accuracy: An ammeter should provide accurate readings of the current in a circuit. The accuracy should be within a reasonable tolerance of the true value of the current being measured.

- Range: A general ammeter should have a wide range of current measurement capabilities so that it can measure a variety of currents, from small to large. It is important to select the correct range for the ammeter to ensure accurate readings.

- Sensitivity: An ammeter should be sensitive enough to measure small currents accurately. This is particularly important when measuring low-level currents in electronic circuits.

- Safety: An ammeter should be designed with safety in mind, so that it can be used without the risk of electric shock or other hazards. It should be properly insulated and designed to withstand the current being measured.

- Durability: An ammeter should be built to withstand the rigors of regular use. It should be constructed with quality materials that can withstand wear and tear over time.

- Display: An ammeter should have a clear and easy-to-read display that indicates the measured current. The display should be large enough to be visible from a distance.

Overall, a good general ammeter should be accurate, versatile, safe, durable, and easy to use. It should meet the specific requirements of the user, whether they are a hobbyist or a professional electrician.

When is Required General Ammeter

A general ammeter is required whenever there is a need to measure the flow of electric current in a circuit. This can be for a wide range of applications, including:

- Electrical Testing: General ammeters are often used in electrical testing to determine the current flow in a circuit. This is important to verify that the circuit is functioning correctly and to troubleshoot any issues that may arise.

- Electronics: General ammeters are commonly used in electronics to measure the current flowing through components such as resistors, capacitors, and transistors. This can help to ensure that the components are functioning correctly and to identify any issues with the circuit.

- Industrial Applications: General ammeters are often used in industrial settings to monitor the current flow in machinery and other equipment. This can help to identify potential issues before they become major problems, and to optimize the performance of the equipment.

- Research: General ammeters are used in scientific research to measure the current flow in experiments. This can help to understand the behavior of materials, and to develop new technologies and products.

Overall, a general ammeter is required whenever there is a need to measure the flow of electric current. It is an essential tool for anyone working with electrical circuits or electronic devices, and is widely used in a variety of applications.

Where is Required General Ammeter

A general ammeter is required wherever there is a need to measure the flow of electric current in a circuit. Some common places where a general ammeter may be required include:

- Electrical Testing Labs: Electrical testing labs use general ammeters to measure current flow in a variety of circuits, including power distribution systems, control circuits, and electronic circuits.

- Industrial Settings: General ammeters are often used in industrial settings to monitor the current flow in machinery and other equipment. This can help to identify potential issues before they become major problems and optimize the performance of the equipment.

- Research Labs: Research labs use general ammeters to measure current flow in experiments, helping to understand the behavior of materials and develop new technologies and products.

- Electrician’s Toolkit: Electricians use general ammeters to measure current flow in residential, commercial, and industrial electrical systems. This helps to identify any faults or issues with the circuit and allows the electrician to troubleshoot and repair the system.

- Hobbyist Workbenches: Hobbyists who work with electronics often have general ammeters as part of their toolkit. This allows them to measure current flow in their circuits and ensure that their projects are working correctly.

Overall, a general ammeter is required wherever there is a need to measure the flow of electric current. They are used in a wide range of settings, from industrial applications to hobbyist workbenches.

How is Required General Ammeter

To use a general ammeter, you need to connect it in series with the circuit that you want to measure the current flow in. Here are the general steps to use a general ammeter:

- Turn off the power supply to the circuit that you want to measure.

- Determine the current range that you want to measure and set the ammeter to that range.

- Connect the ammeter in series with the circuit. This means that you need to interrupt the circuit and connect the ammeter in-line with the current flow.

- Turn on the power supply to the circuit.

- Read the current flow on the ammeter display.

- Turn off the power supply to the circuit.

- Remove the ammeter from the circuit.

It’s important to note that when measuring current with an ammeter, it’s essential to ensure that the ammeter is rated for the correct voltage and current of the circuit being measured. Failure to use an appropriate ammeter can lead to damage or destruction of the ammeter, inaccurate readings, and even safety hazards.

In summary, using a general ammeter requires selecting the appropriate range, connecting it in series with the circuit, and taking a reading. It’s essential to follow safety guidelines and use appropriate equipment when measuring current in a circuit.

Production of General Ammeter

The production of a general ammeter involves a series of steps, including design, manufacturing, assembly, and testing. Here is a general overview of the production process:

- Design: The first step in producing a general ammeter is to design the device. This involves determining the specifications and features of the ammeter, including its accuracy, range, sensitivity, safety features, and display.

- Manufacturing: The components of the ammeter are then manufactured, which may include the circuit board, resistors, capacitors, and other electronic components.

- Assembly: The components are then assembled into the ammeter housing. This may involve soldering the components onto the circuit board, connecting wires, and installing the display and other features.

- Testing: Once the ammeter is assembled, it must be tested to ensure that it meets the required specifications and functions correctly. This may involve using a calibration device to check the accuracy of the ammeter and verifying that it can measure a range of currents accurately.

- Packaging and Distribution: Finally, the ammeter is packaged and distributed to customers. This may involve packaging the ammeter in a protective case or box, including user manuals and instructions, and shipping the device to distributors or retailers.

Overall, the production of a general ammeter involves a combination of electronic manufacturing and assembly, quality testing, and distribution. The process requires specialized skills and expertise to produce a high-quality and accurate device that meets the needs of customers.

Case Study on General Ammeter

Case Study: Measuring Current in an Industrial Control Circuit with a General Ammeter

An industrial facility has a control circuit that regulates the temperature in a manufacturing process. The facility’s engineers need to measure the current flow in the circuit to ensure that it is functioning correctly and to identify any issues that may arise. They decide to use a general ammeter to measure the current.

Here are the steps that they take to measure the current in the circuit:

- They turn off the power supply to the circuit to avoid any safety hazards.

- They select a general ammeter that is rated for the voltage and current of the circuit. They choose an ammeter that can measure a range of currents, as they are not sure of the exact current flow in the circuit.

- They set the ammeter to the appropriate current range and connect it in series with the circuit. They do this by interrupting the circuit and connecting the ammeter in-line with the current flow.

- They turn on the power supply to the circuit and monitor the ammeter display. The display shows that the current flow in the circuit is within the expected range.

- They turn off the power supply to the circuit and remove the ammeter from the circuit.

Based on the measurement, the engineers are confident that the control circuit is functioning correctly, and they can continue to monitor the circuit regularly using the ammeter.

This case study demonstrates how a general ammeter can be used in an industrial setting to measure current flow in a control circuit. By using the ammeter, the engineers can ensure that the circuit is functioning correctly and identify any issues that may arise, helping to optimize the performance of the equipment and maintain safety.

White paper on General Ammeter

Introduction

An ammeter is an instrument used to measure the flow of electric current in a circuit. A general ammeter is an ammeter that can measure a range of currents, making it a versatile instrument for use in a variety of settings. This white paper will explore the features and benefits of a general ammeter, including its uses, applications, and advantages.

Features and Benefits of a General Ammeter

- Accurate Measurement: A general ammeter is designed to measure a range of currents accurately, providing reliable and precise measurements of current flow in a circuit.

- Versatility: A general ammeter can measure a range of currents, making it a versatile instrument that can be used in a variety of applications.

- Easy to Use: A general ammeter is easy to use, with a simple interface and easy-to-read display, making it accessible to a wide range of users.

- Safety: A general ammeter is designed with safety in mind, with features such as overload protection and insulation to prevent electrical hazards.

- Cost-Effective: A general ammeter is an affordable instrument, making it accessible to individuals and businesses on a budget.

Applications of a General Ammeter

- Electrical Engineering: A general ammeter is an essential tool for electrical engineers, who use it to measure current flow in a circuit, troubleshoot electrical problems, and maintain the performance of electrical equipment.

- Manufacturing: General ammeters are used in manufacturing settings to measure current flow in control circuits, helping to ensure the safe and efficient operation of manufacturing equipment.

- Automotive: A general ammeter is used in automotive settings to measure the charging system’s current flow, helping to diagnose and fix issues with the vehicle’s electrical system.

- Renewable Energy: A general ammeter is used in renewable energy systems to measure the current flow in solar panels, wind turbines, and other renewable energy sources.

Conclusion

In summary, a general ammeter is an essential tool for measuring current flow in a variety of applications. Its accuracy, versatility, ease of use, safety features, and affordability make it an excellent choice for individuals and businesses looking to measure current flow in a circuit. Whether you are an electrical engineer, manufacturer, automotive technician, or renewable energy professional, a general ammeter is a valuable instrument that can help you maintain the safety and performance of your equipment.