Metallic Solids

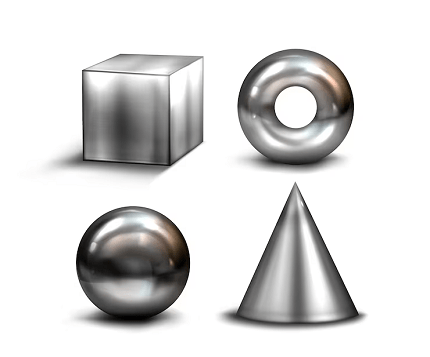

Metallic solids are a type of solid material characterized by a lattice structure of positively charged metal ions held together by a “sea” of delocalized electrons. These materials exhibit metallic bonding, which is responsible for their unique properties.

Key features of metallic solids include:

- Metallic Bonding: Metallic solids have a strong bond between metal atoms due to the attraction between the positively charged metal ions and the delocalized electrons. This bonding allows for the easy movement of electrons, giving rise to high electrical and thermal conductivity.

- Lattice Structure: Metallic solids typically have a crystalline structure composed of repeating unit cells. Common crystal structures include simple cubic, body-centered cubic, face-centered cubic, and hexagonal close-packed.

- Metallic Properties: Metallic solids exhibit several characteristic properties, including luster (shiny appearance), malleability (ability to be hammered into thin sheets), ductility (ability to be drawn into wires), and high tensile strength (ability to withstand pulling forces).

- Electrical Conductivity: Due to the presence of delocalized electrons, metallic solids are excellent conductors of electricity. The delocalized electrons can move freely throughout the lattice and carry electric charge.

- Thermal Conductivity: The delocalized electrons in metallic solids also contribute to high thermal conductivity, allowing efficient transfer of heat through the material.

- Malleability and Ductility: The ability of metallic solids to be hammered into thin sheets or drawn into wires is attributed to the mobility of metal ions and the uniform distribution of delocalized electrons.

- Melting and Boiling Points: Metallic solids generally have high melting and boiling points due to the strong metallic bonding between atoms.

- Alloy Formation: Metallic solids can form alloys by mixing different metals or by adding other elements to a metal. Alloys often exhibit improved properties compared to pure metals, such as increased strength or resistance to corrosion.

- Magnetic Properties: Some metallic solids exhibit magnetic behavior, such as ferromagnetism, where the material can be magnetized in the presence of an external magnetic field.

- Applications: Metallic solids have a wide range of practical applications, including in construction, electrical wiring, automotive industry, aerospace engineering, and electronics.

Understanding the properties and behavior of metallic solids is crucial in various fields, including materials science, metallurgy, and solid-state physics.

The Chemistry syllabus for Metallic Solids in the advanced course at AIIMS typically includes the following topics:

- Metallic Bonding: Introduction to metallic bonding, electron sea model, delocalization of electrons, metallic properties.

- Crystal Structures: Introduction to crystal structures, close packing in one, two, and three dimensions, packing efficiency, unit cell, primitive and non-primitive unit cells.

- Crystal Lattices: Lattice parameters, lattice points, lattice types (simple cubic, body-centered cubic, face-centered cubic, hexagonal close-packed), coordination number, interstitial voids, and packing fractions.

- Defects in Metallic Solids: Point defects (vacancies, interstitials), line defects (dislocations), and their effects on mechanical properties.

- Phase Diagrams: Introduction to phase diagrams, binary phase diagrams for metal-metal systems (eutectic, eutectoid, peritectoid, and peritectoid reactions), lever rule, microstructures, and phase transformations.

- Mechanical Properties: Elastic behavior, Hooke’s law, Young’s modulus, shear modulus, bulk modulus, Poisson’s ratio, plastic deformation, dislocation motion, strengthening mechanisms (solid solution strengthening, precipitation hardening, grain boundary strengthening), and hardness.

- Electrical and Thermal Properties: Electrical conductivity, electronic band structure, free electron theory, Fermi energy, conductors, semiconductors, and insulators. Thermal conductivity and factors affecting it.

- Magnetic Properties: Introduction to magnetic properties, paramagnetic, diamagnetism, ferromagnetism, antiferromagnetic, and ferrimagnetism.

- Superconductivity: Introduction to superconductivity, Meissner effect, critical temperature, type-I and type-II superconductors, BCS theory, and applications.

- Nanomaterials: Introduction to nanomaterials, properties of metallic nanoparticles, synthesis methods, applications in catalysis, electronics, and medicine.

It is important to note that this syllabus is subject to change, and it is recommended to refer to the latest official syllabus or course materials provided by AIIMS for the most accurate and up-to-date information.

What is Required Chemistry syllabus Metallic Solids

The required Chemistry syllabus for Metallic Solids typically covers the following topics:

- Metallic Bonding: Introduction to metallic bonding, electron sea model, delocalization of electrons, and the relationship between metallic bonding and metallic properties.

- Crystal Structures: Introduction to crystal structures, different types of unit cells (simple cubic, body-centered cubic, face-centered cubic, hexagonal close-packed), and their characteristics.

- Crystal Lattices: Lattice parameters, lattice points, coordination number, packing efficiency, and interstitial voids in metallic solids.

- Defects in Metallic Solids: Point defects, such as vacancies and interstitials, and their effects on the properties of metallic solids. Introduction to line defects (dislocations) and their significance in metallic materials.

- Phase Diagrams: Basic understanding of phase diagrams, including binary phase diagrams for metal-metal systems, and the interpretation of phase transformations and microstructures.

- Mechanical Properties: Elastic behavior, Hooke’s law, Young’s modulus, shear modulus, bulk modulus, and Poisson’s ratio. Introduction to plastic deformation, dislocation motion, and strengthening mechanisms in metallic solids.

- Electrical and Thermal Properties: Introduction to electrical conductivity in metallic solids, band theory, Fermi energy, free electron model, and factors affecting electrical conductivity. Basics of thermal conductivity and its relation to lattice structure and electron movement in metallic solids.

- Magnetic Properties: Overview of magnetic properties exhibited by metallic solids, including paramagnetism, diamagnetism, ferromagnetism, antiferromagnetism, and ferrimagnetism.

- Superconductivity: Introduction to superconductivity, Meissner effect, critical temperature, types of superconductors, and the basics of the BCS theory.

- Nanomaterials: Introduction to metallic nanoparticles, synthesis methods, properties of nanoscale metallic materials, and their applications.

It is important to note that the specific details and depth of coverage may vary depending on the educational institution, course level, and curriculum. Students are advised to refer to the official syllabus or course materials provided by their institution for precise information and any updates.

When is Required Chemistry syllabus Metallic Solids

The required Chemistry syllabus for Metallic Solids is typically covered in undergraduate-level courses in materials science, solid-state chemistry, or physical chemistry. The exact timing of when this topic is taught can vary depending on the educational institution and the structure of the curriculum. In many cases, Metallic Solids is introduced as part of a broader course on solid-state chemistry or materials science, which is typically taken by students majoring in Chemistry, Chemical Engineering, Materials Science, or related fields.

In undergraduate programs, the study of Metallic Solids often takes place in the second or third year of the curriculum, following foundational courses in general chemistry and introductory physical chemistry. However, it’s important to note that the specific timing can vary from institution to institution. Students are advised to consult their academic program or course catalog to determine when Metallic Solids is covered in their specific curriculum.

For advanced or specialized courses at the postgraduate level, Metallic Solids may be explored in greater depth and detail, depending on the focus of the program. In such cases, the timing of when the topic is covered will depend on the structure and sequencing of the specific postgraduate program.

Where is Required Chemistry syllabus Metallic Solids

The required Chemistry syllabus for Metallic Solids is typically part of the curriculum in various educational institutions, particularly those offering courses in chemistry, materials science, solid-state chemistry, or physical chemistry. The specific location of this syllabus within an institution’s curriculum can vary, but it is commonly found in undergraduate or graduate programs in these fields.

In undergraduate programs, Metallic Solids is often covered as part of a course or module dedicated to solid-state chemistry or materials science. This course may be offered as an elective or as a required component of the chemistry or materials science curriculum.

At the graduate level, Metallic Solids may be covered in more advanced courses or specialized programs focusing on solid-state chemistry, materials science, or condensed matter physics. These programs typically delve deeper into the fundamental principles and advanced topics related to metallic solids.

It is important to note that the specific location of the Metallic Solids syllabus within an institution’s curriculum may vary. Students should consult their academic program or course catalog, or speak with their academic advisor, to determine the specific course or courses where Metallic Solids is taught.

How is Required Chemistry syllabus Metallic Solids

The required Chemistry syllabus for Metallic Solids is typically taught through a combination of lectures, laboratory experiments, and theoretical discussions. The teaching methods employed may vary depending on the educational institution and the instructor’s approach. However, the following are some common ways in which the syllabus on Metallic Solids is covered:

- Lectures: In-class lectures are often used to introduce and explain the fundamental concepts and principles related to Metallic Solids. The instructor may cover topics such as metallic bonding, crystal structures, defects, phase diagrams, mechanical properties, electrical and thermal properties, magnetic properties, superconductivity, and nanomaterials. Lectures may involve the use of visual aids, such as slides or demonstrations, to enhance understanding.

- Laboratory Experiments: Hands-on laboratory experiments may be conducted to provide students with practical experience and reinforce the concepts learned in lectures. These experiments may include activities such as crystal structure determination, measurement of mechanical properties, electrical and thermal conductivity measurements, and magnetic property investigations. Students may be required to analyze and interpret the experimental data they obtain.

- Problem-Solving Sessions: Problem-solving sessions or tutorials may be conducted to help students apply the concepts learned to solve numerical problems or case studies related to Metallic Solids. These sessions provide an opportunity for students to clarify their doubts and deepen their understanding through interactive discussions with the instructor and fellow classmates.

- Assignments and Projects: Students may be assigned individual or group assignments to further explore specific aspects of Metallic Solids. These assignments may involve literature reviews, research papers, computational simulations, or case studies related to real-world applications of metallic solids. Such assignments encourage independent thinking, research skills, and critical analysis.

- Assessments: Regular assessments, such as quizzes, tests, or exams, may be conducted to evaluate students’ understanding of the syllabus. These assessments can be in the form of multiple-choice questions, short-answer questions, or problem-solving exercises.

It’s important to note that the specific teaching methods may vary depending on the instructor’s preferences and the resources available at the educational institution. Students should refer to the course syllabus and communicate with their instructors for detailed information on how the Metallic Solids syllabus will be taught in their specific course.

Production of Chemistry syllabus Metallic Solids

The production of the Chemistry syllabus for Metallic Solids involves a collaborative effort between curriculum designers, subject matter experts, and educational institutions. Here is an overview of the typical process involved:

- Curriculum Development Team: A team of curriculum developers, which may include academic experts, educators, and curriculum specialists, is responsible for designing the overall Chemistry curriculum. They identify the key topics and learning objectives that should be covered in the syllabus.

- Subject Matter Experts: Subject matter experts in the field of Chemistry, particularly those with expertise in metallic solids, are consulted to provide input on the syllabus. These experts contribute their knowledge, research findings, and industry insights to ensure that the syllabus reflects the current understanding and advancements in the field.

- Review of Educational Standards: The curriculum development team considers educational standards and guidelines provided by relevant educational authorities or accrediting bodies. These standards serve as a benchmark for the content, depth, and level of understanding expected in the Metallic Solids syllabus.

- Content Selection and Sequencing: The curriculum developers determine the specific topics and subtopics to be included in the syllabus. They carefully select content that covers the essential principles, theories, and applications related to metallic solids. The sequencing of topics is planned to facilitate a logical progression of learning, building upon foundational concepts and gradually introducing more advanced topics.

- Learning Objectives and Outcomes: Clear and measurable learning objectives are defined for each topic in the syllabus. These learning objectives specify the knowledge, skills, and competencies that students should acquire upon completion of the course. The curriculum developers ensure that the learning objectives align with the broader educational goals and desired learning outcomes.

- Practical Component: The syllabus may include a practical component, such as laboratory experiments or hands-on activities, to provide students with a practical understanding of metallic solids. The curriculum developers select appropriate experiments that illustrate key concepts and allow students to apply theoretical knowledge in a practical setting.

- Syllabus Review and Validation: The drafted syllabus undergoes a thorough review and validation process. This may involve input and feedback from other faculty members, subject matter experts, and educational stakeholders to ensure its accuracy, comprehensiveness, and alignment with the educational standards and requirements.

- Finalization and Implementation: After incorporating feedback and making necessary revisions, the final version of the Chemistry syllabus for Metallic Solids is produced. It is then implemented in the educational institution as part of the Chemistry curriculum.

It’s important to note that the specific process of syllabus production can vary between institutions and regions. Additionally, the syllabus is subject to periodic review and updates to keep it relevant and aligned with the evolving understanding and advancements in the field of metallic solids.

Case Study on Chemistry syllabus Metallic Solids

Case Study: Application of Metallic Solids in Aerospace Engineering

Introduction: Metallic solids play a crucial role in various industries, and one prominent application is in aerospace engineering. The unique properties of metallic solids, such as their strength, light weight, and high-temperature resistance, make them ideal for use in aircraft and spacecraft components. This case study explores the application of metallic solids in aerospace engineering, specifically focusing on the use of titanium alloys in aircraft manufacturing.

Background: Titanium and its alloys are widely used in the aerospace industry due to their exceptional combination of strength, low density, and corrosion resistance. The key properties of titanium alloys that make them suitable for aerospace applications include high strength-to-weight ratio, excellent heat resistance, and good fatigue performance. These properties enable the design of lighter and more fuel-efficient aircraft while maintaining structural integrity.

Case Study Details: In this case study, we will focus on the use of titanium alloys in the construction of aircraft landing gear components, such as landing gear struts and wheel hubs.

- Landing Gear Struts: Titanium alloys are utilized in landing gear struts due to their high strength and lightweight nature. The struts must withstand the impact forces experienced during landing and provide stability on the ground. Titanium alloys offer superior strength and stiffness, allowing for the design of robust and durable landing gear systems. Additionally, the lightweight nature of titanium alloys helps reduce the overall weight of the aircraft, leading to improved fuel efficiency.

- Wheel Hubs: Titanium alloys are also employed in the manufacture of wheel hubs, which connect the wheels to the landing gear struts. Wheel hubs must withstand the tremendous forces and loads generated during takeoff, landing, and taxiing. Titanium alloys offer excellent fatigue resistance, enabling them to withstand repeated loading and unloading cycles without failure. The corrosion resistance of titanium alloys is particularly advantageous in wheel hubs, as they are exposed to harsh environmental conditions and various fluids like de-icing agents and hydraulic fluids.

Benefits and Challenges: The use of metallic solids, specifically titanium alloys, in aerospace engineering brings several benefits but also poses challenges:

Benefits:

- High strength-to-weight ratio: Titanium alloys offer excellent strength properties while being lightweight, contributing to fuel efficiency and increased payload capacity.

- Corrosion resistance: Titanium alloys have excellent resistance to corrosion, reducing maintenance requirements and extending the service life of aircraft components.

- Fatigue performance: Titanium alloys exhibit superior fatigue resistance, allowing them to withstand cyclic loading and ensuring long-term structural integrity.

- High-temperature resistance: Titanium alloys maintain their strength and structural stability at elevated temperatures, making them suitable for applications in high-temperature environments, such as jet engines.

Challenges:

- Cost: Titanium alloys can be more expensive compared to other materials, which can increase the overall manufacturing costs of aerospace components.

- Machinability: Titanium alloys are notoriously difficult to machine, requiring specialized equipment and techniques, which adds complexity to the manufacturing process.

- Joining: Joining titanium alloys can be challenging due to their low thermal conductivity and high reactivity, necessitating specialized welding and bonding techniques.

Conclusion: The application of metallic solids, particularly titanium alloys, in aerospace engineering plays a vital role in the development of efficient and reliable aircraft. The unique properties of titanium alloys, including their high strength-to-weight ratio, corrosion resistance, fatigue performance, and high-temperature resistance, make them ideal for critical components such as landing gear struts and wheel hubs. However, the challenges associated with the cost, machinability, and joining of titanium alloys require careful consideration during the design and manufacturing processes. Overall, the use of metallic solids in aerospace engineering demonstrates the importance of material selection and engineering expertise in achieving optimal performance and safety in aircraft operations.

White paper on Chemistry syllabus Metallic Solids

Title: Advancements in Metallic Solids: Unleashing the Potential for Future Applications

Abstract:

This white paper explores the remarkable world of metallic solids and highlights their significant contributions across various industries. Metallic solids, characterized by their unique bonding and structural properties, have been instrumental in shaping modern technology and infrastructure. This paper provides an overview of metallic solids, their key properties, and their applications in sectors such as aerospace, automotive, electronics, and energy. Furthermore, it delves into recent advancements in metallic solids, including the development of novel alloys, innovative manufacturing techniques, and emerging applications. By examining the evolving landscape of metallic solids, this white paper aims to inspire researchers, engineers, and industry professionals to leverage their potential for future advancements and breakthroughs.

Introduction

a. Definition and characteristics of metallic solids

b. Importance and relevance of metallic solids in modern society

Metallic Bonding and Structural Properties

a. Explanation of metallic bonding and its influence on properties

b. Crystal structures and lattice arrangements in metallic solids

c. Mechanical, electrical, thermal, and magnetic properties of metallic solids

Applications of Metallic Solids

a. Aerospace: Lightweight alloys for aircraft components

b. Automotive: High-strength materials for vehicle structures and engines

c. Electronics: Conductive materials for wiring and electrical components

d. Energy: Metallic solids in renewable energy systems and power generation

e. Construction and Infrastructure: Steel and other metallic materials for buildings and bridges

Advancements in Metallic Solids

a. Alloy Development: Tailoring properties through alloy composition

b. Additive Manufacturing: 3D printing of complex metallic structures

c. Nanostructured Metallic Solids: Enhanced properties at the nanoscale

d. Surface Engineering: Coatings and treatments for improved performance

e. Biomimetic Metallic Solids: Inspiration from nature for new applications

Challenges and Future Directions

a. Cost-effectiveness and scalability of metallic solids

b. Sustainability and environmental considerations

c. Exploring uncharted territories: Potential applications in medicine, space exploration, and more

Conclusion

a. Recap of the importance and versatility of metallic solids

b. Call to embrace innovation and collaboration for further advancements

As metallic solids continue to shape our world, this white paper aims to inspire researchers, engineers, and decision-makers to recognize the immense potential of metallic solids and explore their applications in various fields. By capitalizing on recent advancements and pushing the boundaries of knowledge, we can unlock new possibilities and usher in a future where metallic solids play an even more integral role in technology, infrastructure, and human progress.