The cyanide process is a hydrometallurgical technique used to extract gold and silver from low-grade ores by converting them into soluble cyanide complexes. This process was first developed in the late 19th century and has since become the most commonly used method for extracting gold and silver from ores.

The process involves the following steps:

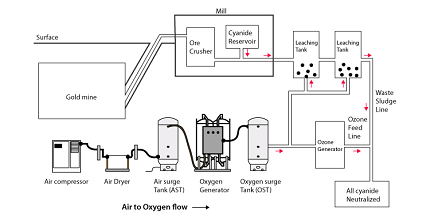

- Grinding: The ore is crushed into a fine powder and mixed with water to form a slurry.

- Leaching: The slurry is then treated with a dilute solution of sodium cyanide (NaCN) and air is bubbled through the mixture. The cyanide reacts with the gold and silver in the ore to form soluble complexes.

- Adsorption: The gold and silver complexes are then adsorbed onto activated carbon particles in a process called carbon-in-pulp (CIP).

- Desorption: The loaded carbon is then stripped of the gold and silver using a caustic cyanide solution in a process called elution.

- Electrowinning: The gold and silver are then recovered from the eluate by electroplating onto cathodes.

- Smelting: The cathodes are then melted to produce doré bars, which contain a mixture of gold and silver.

The cyanide process is very efficient, with a typical recovery rate of 95-98% for gold and 70-80% for silver. However, it is also highly toxic, and great care must be taken to prevent cyanide from contaminating the environment. The use of cyanide in mining has come under increasing scrutiny in recent years due to environmental concerns, and alternative methods such as thiosulfate leaching are being explored as possible alternatives.

What is Required Isolation of Metals Cyanide process (silver and gold)

The isolation of metals in the cyanide process involves several steps to ensure the safety of workers and prevent the release of toxic cyanide into the environment. These steps include:

- Designated area: The cyanide process should take place in a designated area that is isolated from other activities and has controlled access. This area should have appropriate ventilation and be designed to contain spills.

- Protective equipment: Workers involved in the cyanide process should wear appropriate protective equipment, including respirators, gloves, and protective clothing.

- Cyanide storage and handling: Cyanide should be stored in a secure location and handled carefully to prevent spills or leaks. Workers should be trained in the safe handling and storage of cyanide.

- Cyanide destruction: After the cyanide process is complete, any remaining cyanide must be destroyed before the waste is discharged. This can be done using various methods, including chemical oxidation or biological degradation.

- Waste management: Any waste generated during the cyanide process should be carefully managed to prevent contamination of the environment. This may include treatment, neutralization, or disposal in a secure landfill.

- Monitoring: Regular monitoring should be conducted to ensure that cyanide levels in the environment are within safe limits. This may involve sampling of air, water, and soil, as well as monitoring of workers’ exposure to cyanide.

Overall, the isolation of metals in the cyanide process requires careful planning, training, and monitoring to ensure the safety of workers and prevent environmental contamination.

When is Required Isolation of Metals Cyanide process (silver and gold)

The isolation of metals in the cyanide process is required whenever the cyanide process is used to extract gold and silver from ores. This process is commonly used in the mining industry, where it is used to extract gold and silver from low-grade ores.

The isolation of metals is necessary to ensure the safety of workers and prevent the release of toxic cyanide into the environment. Cyanide is highly toxic, and exposure to even small amounts can be deadly. Therefore, the cyanide process must be conducted in a designated area that is isolated from other activities, with controlled access and appropriate ventilation.

In addition, workers involved in the cyanide process must wear appropriate protective equipment, and cyanide must be stored and handled carefully to prevent spills or leaks. Any waste generated during the process must be carefully managed, and any remaining cyanide must be destroyed before the waste is discharged.

Overall, the isolation of metals in the cyanide process is necessary whenever the cyanide process is used to extract gold and silver from ores to ensure the safety of workers and prevent environmental contamination.

Where is Required Isolation of Metals Cyanide process (silver and gold)

The required isolation of metals in the cyanide process (silver and gold) takes place in a designated area, usually located in a mining facility or processing plant. The area should be isolated from other activities to prevent the contamination of other areas or products.

The isolation area for the cyanide process must be equipped with appropriate safety features, such as ventilation systems to prevent the buildup of toxic gases, safety equipment, and warning signs. The area should also have controlled access to prevent unauthorized entry and reduce the risk of accidents.

In addition, the cyanide process area should be designed to contain any spills or leaks that may occur during the process. Spill containment systems, such as bunds or secondary containment, can help prevent the release of cyanide into the environment and protect workers from exposure.

Overall, the required isolation of metals in the cyanide process takes place in a dedicated area that is designed to ensure the safety of workers and prevent environmental contamination.

How is Required Isolation of Metals Cyanide process (silver and gold)

The required isolation of metals in the cyanide process (silver and gold) is achieved through a combination of engineering controls, administrative controls, and personal protective equipment (PPE).

Engineering controls involve designing the process and the facility in a way that minimizes exposure to cyanide. For example, the cyanide process is conducted in a designated area with controlled access and appropriate ventilation systems to prevent the buildup of toxic gases.

Administrative controls involve policies and procedures that are put in place to reduce exposure to cyanide. This includes the use of warning signs, training programs, and strict protocols for handling and storing cyanide.

Personal protective equipment (PPE) is also used to protect workers from exposure to cyanide. This may include respirators, gloves, and protective clothing that are designed to prevent skin contact and inhalation of cyanide.

In addition, spill containment systems and other safety measures are put in place to prevent the release of cyanide into the environment. This may include the use of bunds or secondary containment systems to contain any spills or leaks that may occur during the cyanide process.

Overall, the required isolation of metals in the cyanide process (silver and gold) is achieved through a combination of engineering controls, administrative controls, and personal protective equipment to ensure the safety of workers and prevent environmental contamination.

Nomenclature of Isolation of Metals Cyanide process (silver and gold)

The nomenclature of the isolation of metals in the cyanide process (silver and gold) refers to the various steps and components involved in the process. Here are some common terms used in the nomenclature of the cyanide process:

- Crushing and grinding: The process of reducing the size of the ore to prepare it for the cyanide leaching process.

- Cyanide leaching: The process of dissolving gold or silver in a cyanide solution to extract the metal from the ore.

- Carbon adsorption: The process of removing gold or silver from the cyanide solution by adsorbing it onto activated carbon.

- Elution: The process of removing gold or silver from the activated carbon by washing it with a hot caustic solution.

- Electrowinning: The process of extracting gold or silver from the pregnant cyanide solution by passing an electric current through the solution to plate the metal onto electrodes.

- Smelting: The process of melting the gold or silver precipitate to produce a doré bar, which is a semi-pure alloy of gold and silver.

- Refining: The process of purifying the doré bar to produce pure gold or silver.

Overall, the nomenclature of the isolation of metals in the cyanide process involves a series of steps that convert the ore into pure gold or silver. The process is carefully designed and monitored to ensure worker safety and prevent environmental contamination.

Case Study on Isolation of Metals Cyanide process (silver and gold)

One example of the isolation of metals using the cyanide process (silver and gold) is the operation of the Veladero mine in Argentina, which is owned and operated by Barrick Gold Corporation.

The Veladero mine is located in the San Juan Province of Argentina and is one of the largest gold mines in South America. The mine produces gold and silver using the cyanide process, which involves the following steps:

- Crushing and grinding: The ore is crushed and ground to a fine powder to prepare it for the cyanide leaching process.

- Cyanide leaching: The finely ground ore is mixed with a dilute cyanide solution, which dissolves the gold and silver in the ore.

- Carbon adsorption: The cyanide solution is passed through a series of tanks containing activated carbon, which adsorbs the gold and silver.

- Elution: The gold and silver are removed from the activated carbon by washing it with a hot caustic solution, which leaves a pregnant cyanide solution.

- Electrowinning: The gold and silver are extracted from the pregnant cyanide solution by passing an electric current through the solution to plate the metal onto electrodes.

- Smelting: The gold and silver precipitate is melted to produce a doré bar, which is a semi-pure alloy of gold and silver.

- Refining: The doré bar is further purified to produce pure gold or silver.

To ensure the safety of workers and prevent environmental contamination, the Veladero mine has implemented a number of measures to isolate the cyanide process:

- The cyanide process is conducted in a designated area of the mine that is isolated from other activities.

- Workers involved in the cyanide process wear appropriate personal protective equipment, including respirators, gloves, and protective clothing.

- The mine has implemented spill containment systems and other safety measures to prevent the release of cyanide into the environment.

- The mine has a comprehensive training program for workers involved in the cyanide process, which covers safety procedures and the proper handling and storage of cyanide.

Overall, the isolation of metals using the cyanide process (silver and gold) at the Veladero mine demonstrates the importance of implementing safety measures to protect workers and prevent environmental contamination. The mine’s careful design and monitoring of the cyanide process have allowed it to operate safely and efficiently while producing significant amounts of gold and silver.

White paper on Isolation of Metals Cyanide process (silver and gold)

Here is a white paper on the isolation of metals using the cyanide process (silver and gold):

Introduction:

The cyanide process is a widely used method for extracting gold and silver from their ores. The process involves the dissolution of the metal in a cyanide solution, followed by the recovery of the metal from the solution using various techniques such as carbon adsorption, electrowinning, and smelting. The cyanide process is an effective way to extract gold and silver, but it is also potentially dangerous due to the toxicity of cyanide. Therefore, it is essential to isolate the cyanide process to protect workers and prevent environmental contamination.

Isolation of the Cyanide Process:

The isolation of the cyanide process involves several steps to ensure worker safety and prevent environmental contamination. These steps include:

- Designated Area: The cyanide process is conducted in a designated area of the mine or processing plant that is isolated from other activities. This area should be clearly marked and restricted to authorized personnel only.

- Personal Protective Equipment: Workers involved in the cyanide process should wear appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. PPE should be properly fitted and maintained to ensure maximum protection.

- Spill Containment: The mine or processing plant should have spill containment systems in place to prevent the release of cyanide into the environment. Spill kits and spill response procedures should be readily available and workers should be trained in their use.

- Storage and Handling: Cyanide should be stored and handled in accordance with local regulations and best practices. Storage containers should be clearly labeled and stored in a designated area. Workers should be trained in the proper handling and storage of cyanide.

- Training: Workers involved in the cyanide process should receive comprehensive training on safety procedures and the proper handling and storage of cyanide. Training should be conducted on a regular basis and include refresher courses.

Techniques for Recovering Gold and Silver:

The cyanide process involves several techniques for recovering gold and silver from the cyanide solution. These techniques include:

- Carbon Adsorption: The cyanide solution is passed through a series of tanks containing activated carbon, which adsorbs the gold and silver. The carbon is then stripped of the gold and silver using a hot caustic solution.

- Electrowinning: The gold and silver are extracted from the pregnant cyanide solution by passing an electric current through the solution to plate the metal onto electrodes. The electrodes are then washed to remove the metal precipitate.

- Smelting: The gold and silver precipitate is melted to produce a doré bar, which is a semi-pure alloy of gold and silver. The doré bar is further refined to produce pure gold or silver.

Conclusion:

The isolation of the cyanide process is essential to protect workers and prevent environmental contamination. The design and monitoring of the cyanide process should be carefully planned to ensure maximum safety and efficiency. Comprehensive training and the use of appropriate PPE are critical to minimizing the risks associated with the cyanide process. The recovery techniques used in the cyanide process, such as carbon adsorption, electrowinning, and smelting, are effective ways to extract gold and silver from their ores. Overall, the isolation of the cyanide process is a critical component of the mining and refining industry and should be given the utmost attention and care.