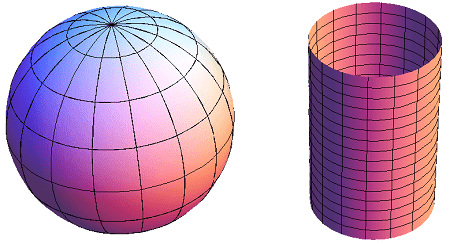

Cylinders and spheres are both three-dimensional shapes commonly encountered in mathematics and the physical world. Here are some important characteristics of each shape:

Cylinder:

- A cylinder has two circular bases that are parallel and congruent.

- The sides of a cylinder are formed by connecting the edges of the two bases with straight lines.

- The height of a cylinder is the perpendicular distance between the two bases.

Spheres:

- A sphere is a three-dimensional shape that is perfectly round in every direction, like a ball.

- A sphere is defined as the set of all points in space that are equidistant from a given point, called the center of the sphere.

- The radius of a sphere is the distance from the center to any point on the surface of the sphere.

- The diameter of a sphere is twice the radius.

Both cylinders and spheres have properties that make them useful in a variety of applications. For example, cylinders are commonly used as containers for liquids or gases because they have a uniform cross-sectional area and can hold a large volume of material. Spheres are useful in situations where an object needs to be as compact as possible while still having a large surface area, such as in the design of ball bearings or planetary gears.

What is Required Mechanics Cylinders and Spheres

In the field of mechanics, cylinders and spheres have specific properties and behaviors that are important to understand. Here are some key concepts related to cylinders and spheres in mechanics:

Cylinders:

- The volume of a cylinder is given by the formula V = πr^2h, where r is the radius of the base and h is the height.

- The surface area of a cylinder is given by the formula A = 2πr^2 + 2πrh.

- Cylinders have moments of inertia, which determine how they rotate and respond to forces. The moment of inertia of a solid cylinder is given by I = (1/2)mr^2, where m is the mass of the cylinder.

- When a force is applied to a cylinder, the cylinder may undergo compression, tension, or bending depending on the direction and magnitude of the force.

Spheres:

- The volume of a sphere is given by the formula V = (4/3)πr^3, where r is the radius.

- The surface area of a sphere is given by the formula A = 4πr^2.

- Spheres have moments of inertia, which determine how they rotate and respond to forces. The moment of inertia of a solid sphere is given by I = (2/5)mr^2, where m is the mass of the sphere.

- When a force is applied to a sphere, the sphere may undergo compression or tension, but it will not bend due to its symmetry.

In addition to these properties, cylinders and spheres also have important applications in fluid mechanics, where they are used to model the behavior of fluids in pipes, containers, and other systems. For example, the Bernoulli’s principle can be applied to the flow of fluids through cylindrical pipes, and the drag force on a sphere moving through a fluid can be calculated using the Reynolds number.

When is Required Mechanics Cylinders and Spheres

Required Mechanics Cylinders and Spheres are used in a wide range of fields and applications, including but not limited to:

- Engineering: In engineering, cylinders and spheres are commonly used in the design of mechanical systems, such as engines, turbines, and pumps. Understanding the mechanics of these shapes is essential in determining their strength, durability, and performance.

- Physics: In physics, cylinders and spheres are used to model a wide range of physical phenomena, from the behavior of fluids to the motion of planets. Mechanics of these shapes plays a critical role in analyzing and understanding these phenomena.

- Architecture: In architecture, cylinders and spheres are used to design structures that are aesthetically pleasing, structurally sound, and energy-efficient. Understanding the mechanics of these shapes can help architects and engineers to optimize the design of buildings and other structures.

- Manufacturing: In manufacturing, cylinders and spheres are used in the production of a wide range of products, including pipes, bearings, and ball joints. Understanding the mechanics of these shapes is essential in ensuring that these products are produced to the required specifications and standards.

- Robotics: In robotics, cylinders and spheres are used in the design of robotic systems that can move, manipulate, and interact with their environment. Understanding the mechanics of these shapes is essential in developing robotic systems that are safe, efficient, and effective.

Overall, Required Mechanics Cylinders and Spheres are essential in many fields and applications where understanding the behavior of these shapes is important for the design, analysis, and optimization of mechanical systems, structures, and processes.

Where is Required Mechanics Cylinders and Spheres

Required Mechanics Cylinders and Spheres are used in many different industries and fields that require an understanding of the behavior and properties of these shapes. Here are some specific examples of where Required Mechanics Cylinders and Spheres may be used:

- Aerospace: In the aerospace industry, cylinders and spheres are used in the design and construction of aircraft, rockets, and satellites. Understanding the mechanics of these shapes is essential in ensuring that these vehicles are safe, efficient, and reliable.

- Automotive: In the automotive industry, cylinders and spheres are used in the design and construction of engines, transmissions, and suspension systems. Understanding the mechanics of these shapes is essential in ensuring that these systems are durable, efficient, and perform well.

- Construction: In the construction industry, cylinders and spheres are used in the design and construction of buildings, bridges, and other structures. Understanding the mechanics of these shapes is essential in ensuring that these structures are safe, structurally sound, and able to withstand the forces of nature.

- Manufacturing: In the manufacturing industry, cylinders and spheres are used in the production of a wide range of products, from pipes and valves to bearings and ball joints. Understanding the mechanics of these shapes is essential in ensuring that these products are produced to the required specifications and standards.

- Robotics: In the robotics industry, cylinders and spheres are used in the design and construction of robotic systems that can move, manipulate, and interact with their environment. Understanding the mechanics of these shapes is essential in developing robotic systems that are safe, efficient, and effective.

Overall, Required Mechanics Cylinders and Spheres are used in many different industries and fields where understanding the behavior and properties of these shapes is essential for the design, construction, and operation of mechanical systems, structures, and processes.

How is Required Mechanics Cylinders and Spheres

Required Mechanics Cylinders and Spheres are studied using principles of physics and mechanics. Here are some key concepts and equations used to understand the mechanics of cylinders and spheres:

- Forces: Cylinders and spheres can be subject to a variety of forces, including compression, tension, bending, and shearing. These forces can be calculated using equations that describe the stress and strain on the material.

- Moment of inertia: The moment of inertia describes how difficult it is to rotate an object around a particular axis. For cylinders and spheres, the moment of inertia is dependent on the mass and shape of the object, and can be calculated using specific equations.

- Torque: Torque is a measure of the rotational force applied to an object, and can be calculated using equations that describe the moment of inertia and the angular acceleration of the object.

- Fluid mechanics: Cylinders and spheres are commonly used in fluid mechanics to model the behavior of fluids in pipes, containers, and other systems. Bernoulli’s principle can be applied to the flow of fluids through cylindrical pipes, and the drag force on a sphere moving through a fluid can be calculated using the Reynolds number.

- Energy: The energy of a cylinder or sphere can be calculated using equations that describe the potential and kinetic energy of the object. This is important in understanding how much energy is required to move or deform the object.

Overall, Required Mechanics Cylinders and Spheres are studied using a combination of mathematical equations, experimental observations, and computational simulations. This allows engineers, physicists, and other scientists to understand the mechanics of these shapes, and to apply this knowledge in the design, construction, and operation of mechanical systems, structures, and processes.

Production of Mechanics Cylinders and Spheres

Mechanical cylinders and spheres are produced using a variety of methods depending on the material, size, and application. Here are some common production methods for mechanical cylinders and spheres:

- Casting: Metal cylinders and spheres can be produced through casting, which involves pouring molten metal into a mold and allowing it to solidify. This method can produce large and complex shapes, but may have limitations in terms of accuracy and surface finish.

- Forging: Forging involves shaping metal cylinders and spheres by applying pressure to a heated metal billet using a die. This method can produce high-strength and precise shapes, but may have limitations in terms of complexity and size.

- Extrusion: Extrusion involves pushing a material through a die to produce a continuous shape, such as a cylindrical tube or a sphere. This method is commonly used for producing plastic and metal cylinders with high accuracy and uniformity.

- Machining: Mechanical cylinders and spheres can also be produced through machining, which involves removing material from a larger block using cutting tools. This method can produce high-precision shapes with tight tolerances, but may be time-consuming and expensive.

- Additive manufacturing: Additive manufacturing, also known as 3D printing, can produce mechanical cylinders and spheres by building up layers of material using a computer-controlled printing process. This method is becoming more popular for producing customized and complex shapes with a high degree of accuracy.

Overall, the production of mechanical cylinders and spheres involves a variety of methods depending on the material, size, and application. Each method has its own advantages and limitations, and engineers and manufacturers must select the appropriate method based on their specific requirements.

Case Study on Mechanics Cylinders and Spheres

One example of how Required Mechanics Cylinders and Spheres are used in real-world applications is in the design and construction of hydraulic cylinders for heavy equipment, such as excavators and bulldozers.

Hydraulic cylinders are used in these machines to convert hydraulic energy into mechanical force, which is used to lift and move heavy loads. The hydraulic cylinder consists of a cylinder barrel, a piston, and a piston rod. The cylinder barrel is a cylindrical tube that contains the piston and allows it to move back and forth. The piston is a solid cylinder that fits snugly inside the cylinder barrel and is sealed to prevent fluid from leaking out. The piston rod is attached to the piston and extends out of the cylinder barrel, providing a connection point for other components in the hydraulic system.

The design of the hydraulic cylinder is critical to its performance and reliability. Engineers must consider factors such as the size and weight of the load, the pressure and flow rate of the hydraulic fluid, and the expected operating conditions. They must also ensure that the cylinder is strong enough to withstand the forces and stresses imposed on it during operation.

To design a hydraulic cylinder, engineers use principles of mechanics and physics to calculate the stresses and strains on the cylinder components. For example, they may use equations to calculate the maximum stress on the cylinder barrel due to the hydraulic pressure, or the maximum stress on the piston rod due to the applied force.

Manufacturing of the hydraulic cylinder also requires expertise in Required Mechanics Cylinders and Spheres. The cylinder barrel and piston are typically produced using metal casting or extrusion methods, which require precise control of the manufacturing process to ensure that the parts meet the required specifications. The piston rod is typically produced using machining methods, which require high precision and accuracy to ensure a proper fit with the piston and cylinder barrel.

Overall, Required Mechanics Cylinders and Spheres are critical to the design and manufacturing of hydraulic cylinders for heavy equipment. These components must be carefully designed and manufactured to withstand the stresses and forces imposed on them during operation, and to ensure the safe and reliable operation of the equipment.

White paper on Mechanics Cylinders and Spheres

Introduction

Mechanical cylinders and spheres play a crucial role in a wide range of industrial applications, from heavy equipment like hydraulic cylinders to aerospace components. These components require a deep understanding of mechanics and physics to ensure they are designed and manufactured to meet strict standards for strength, durability, and precision. This white paper will explore the principles of Required Mechanics Cylinders and Spheres, their applications, and the manufacturing processes used to produce them.

Principles of Mechanics Cylinders and Spheres

Mechanical cylinders and spheres are designed to withstand the stresses and forces imposed on them during operation. This requires a thorough understanding of the principles of mechanics, including statics and dynamics, materials science, and thermodynamics. Engineers must consider factors such as the size and weight of the load, the pressure and flow rate of the fluid, and the expected operating conditions to determine the optimal design parameters for the cylinder or sphere.

One of the key principles of mechanics cylinders and spheres is the concept of stress and strain. Stress is defined as the force per unit area applied to a material, while strain is the deformation that results from that force. Engineers must ensure that the cylinder or sphere can withstand the stresses and strains imposed on it without deforming or breaking.

Another important principle is the concept of fluid mechanics. Hydraulic and pneumatic cylinders and spheres rely on the properties of fluids to generate force and motion. Engineers must consider factors such as fluid viscosity, flow rate, and pressure to ensure the cylinder or sphere can operate effectively.

Applications of Mechanics Cylinders and Spheres

Mechanical cylinders and spheres have a wide range of applications in various industries. Some common applications include:

- Hydraulic and pneumatic cylinders: These are used in heavy equipment, such as excavators and bulldozers, to convert hydraulic or pneumatic energy into mechanical force.

- Aerospace components: Mechanical cylinders and spheres are used in aircraft landing gear, hydraulic systems, and other components that require precision and reliability.

- Automotive components: These are used in shock absorbers, power steering systems, and other components that require precise motion control and durability.

- Medical equipment: Mechanical cylinders and spheres are used in medical devices, such as infusion pumps and ventilators, to provide precise motion control and fluid delivery.

Manufacturing Processes for Mechanics Cylinders and Spheres

The manufacturing of mechanical cylinders and spheres requires expertise in a variety of production methods, including casting, forging, extrusion, machining, and additive manufacturing. Each method has its advantages and limitations, and the selection of the appropriate method depends on the specific requirements of the application.

For example, casting is commonly used to produce metal cylinders and spheres that require complex shapes, but it may have limitations in terms of accuracy and surface finish. Forging is used to produce high-strength and precise shapes, but it may have limitations in terms of complexity and size. Machining can produce high-precision shapes with tight tolerances, but it can be time-consuming and expensive. Additive manufacturing is becoming more popular for producing customized and complex shapes with a high degree of accuracy.

Conclusion

Mechanical cylinders and spheres are critical components in a wide range of industrial applications, from heavy equipment to medical devices. The design and manufacture of these components require expertise in Required Mechanics Cylinders and Spheres and a deep understanding of the principles of mechanics, materials science, and fluid mechanics. By applying these principles and selecting the appropriate manufacturing process, engineers and manufacturers can produce high-quality, reliable, and precise mechanical cylinders and spheres that meet the needs of their applications.