The density of alkenes and alkynes depends on the specific compound and its molecular weight, as well as the temperature and pressure at which it is measured.

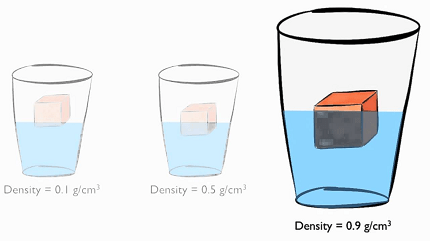

In general, alkenes and alkynes are less dense than water and most of them are gases or liquids at room temperature and pressure. However, some of them can be solids or waxy materials, such as polyethylene, which is a common plastic made from ethene.

For example, ethene (C2H4) has a density of 0.968 g/mL at standard conditions (25°C and 1 atm), while propyne (C3H4) has a density of 0.695 g/mL under the same conditions. These values can vary depending on the specific isomer or configuration of the molecule.

It’s also worth noting that the density of alkenes and alkynes can change with temperature and pressure. As temperature increases, the density of a gas decreases, while as pressure increases, the density of a gas increases. This can have important implications in chemical reactions and industrial processes involving alkenes and alkynes.

What is Required Alkenes and Alkynes Density

The required density of alkenes and alkynes depends on their intended use or application. For example, if an alkene or alkyne is being used as a fuel, it should have a density that allows for efficient storage and transportation, while also providing high energy content.

Similarly, if an alkene or alkyne is being used as a chemical feedstock for manufacturing, its density should be suitable for handling and processing in industrial equipment. In some cases, a specific density may be required for a particular application, such as in the production of polymer materials.

It’s also important to consider other physical and chemical properties of alkenes and alkynes, such as boiling point, melting point, reactivity, and toxicity, when selecting a particular compound for a specific application.

Overall, the required density of alkenes and alkynes will vary depending on the specific application and the properties needed for that application.

When is Required Alkenes and Alkynes Density

The required density of alkenes and alkynes is an important consideration in a variety of applications, including:

- Fuel: Alkenes and alkynes are commonly used as fuels in engines and other combustion systems. The density of the fuel affects its energy content and also determines how much fuel can be stored in a given volume. This is especially important in transportation and aerospace industries, where weight and space constraints are critical factors.

- Chemical production: Alkenes and alkynes are important chemical feedstocks used in the production of a wide range of chemicals, such as plastics, solvents, and pharmaceuticals. The density of the feedstock can affect how it is transported and processed, as well as the efficiency of the reaction.

- Polymer production: Alkenes and alkynes are used to produce a variety of polymers, such as polyethylene and polypropylene. The density of the alkene or alkyne used in polymer production affects the physical properties of the resulting polymer, such as its strength, flexibility, and durability.

- Solvents: Alkenes and alkynes can be used as solvents in various industries, such as pharmaceuticals and electronics. The density of the solvent can affect its ability to dissolve certain materials and also how it behaves in industrial processes.

Overall, the required density of alkenes and alkynes depends on the specific application and the properties needed for that application. It is an important consideration in many industries and can impact the efficiency, safety, and cost-effectiveness of a particular process or product.

Where is Required Alkenes and Alkynes Density

The required density of alkenes and alkynes is important in various industries and applications, including:

- Petrochemical industry: Alkenes and alkynes are important feedstocks for the production of various chemicals and materials, including plastics, solvents, and synthetic fibers. The density of the feedstock affects how it is transported and processed, as well as the efficiency of the reaction.

- Transportation industry: Alkenes and alkynes are used as fuels for engines and other combustion systems in the transportation industry. The density of the fuel affects its energy content and also determines how much fuel can be stored in a given volume, which is important for both land and air transportation.

- Polymer industry: Alkenes and alkynes are used in the production of various polymers, including polyethylene, polypropylene, and PVC. The density of the alkene or alkyne used in polymer production affects the physical properties of the resulting polymer, such as its strength, flexibility, and durability.

- Solvents industry: Alkenes and alkynes are used as solvents in various industries, including pharmaceuticals, electronics, and paints and coatings. The density of the solvent affects its ability to dissolve certain materials and also how it behaves in industrial processes.

- Agricultural industry: Alkenes and alkynes are used in the production of pesticides, herbicides, and fertilizers. The density of the chemical affects how it is transported and stored, as well as its effectiveness in controlling pests and promoting plant growth.

Overall, the required density of alkenes and alkynes is an important consideration in many industries and applications, where it can impact the efficiency, safety, and cost-effectiveness of a particular process or product.

How is Required Alkenes and Alkynes Density

The required density of alkenes and alkynes can be achieved through various methods, including:

- Chemical synthesis: The density of alkenes and alkynes can be tailored through chemical synthesis, where different reaction conditions can be used to produce compounds with specific densities. For example, different catalysts and reaction conditions can be used to produce alkenes and alkynes with different molecular weights and densities.

- Fractional distillation: Alkenes and alkynes can be separated from other compounds and purified through fractional distillation, a process that involves heating and cooling the mixture to separate the components based on their boiling points. This can be used to isolate alkenes and alkynes with specific densities for use in different applications.

- Blending: Alkenes and alkynes with different densities can be blended together to achieve a desired density. This can be done by mixing two or more compounds together in specific ratios to achieve a targeted density that meets the requirements of a particular application.

- Modification of molecular structure: The density of alkenes and alkynes can also be modified by changing their molecular structure. For example, branching or adding functional groups to the molecule can affect its density and other physical properties.

Overall, the method used to achieve the required density of alkenes and alkynes will depend on the specific application and the properties needed for that application. A variety of methods can be used, including chemical synthesis, fractional distillation, blending, and modification of molecular structure.

Production of Alkenes and Alkynes Density

The production of alkenes and alkynes can be achieved through various methods, and the density of the resulting products depends on the specific method used. Here are some common methods for producing alkenes and alkynes and how they can affect density:

- Steam cracking: This is a common method for producing alkenes from hydrocarbons such as ethane and propane. The process involves heating the hydrocarbons in the presence of steam, which breaks down the molecules into smaller fragments, including alkenes. The resulting alkenes have a relatively low density.

- Catalytic cracking: This is another method for producing alkenes from hydrocarbons, and it involves heating the hydrocarbons in the presence of a catalyst. The catalyst breaks the molecules down into smaller fragments, including alkenes. The density of the resulting alkenes can vary depending on the type of catalyst used and the reaction conditions.

- Dehydrogenation: This is a method for producing alkynes from alkenes, and it involves removing hydrogen atoms from the alkene molecule. The resulting alkynes have a higher density than the original alkenes.

- Acetylene production: Acetylene is an important alkyne that is used in a variety of applications, including welding and chemical synthesis. It can be produced by reacting calcium carbide with water, which produces acetylene gas. The density of the acetylene gas depends on the temperature and pressure at which it is produced.

- Metathesis: This is a method for producing alkenes and alkynes from other alkenes and alkynes. It involves the exchange of carbon-carbon double or triple bonds between molecules, resulting in the formation of new alkenes and alkynes. The density of the resulting products can vary depending on the specific reactants and reaction conditions used.

Overall, the production of alkenes and alkynes can involve a variety of methods, and the density of the resulting products can depend on the specific method used and the reaction conditions.

Case Study on Alkenes and Alkynes Density

One example of the importance of alkenes and alkynes density in industry can be seen in the production of polypropylene, a common plastic used in a variety of applications. Polypropylene is produced by polymerizing propylene, an alkene, using a catalyst.

The density of the resulting polypropylene depends on the density of the propylene used in the polymerization process. Low-density polypropylene (LDPE) is produced using low-density propylene, which typically has a density of around 0.88 g/cm³. In contrast, high-density polypropylene (HDPE) is produced using high-density propylene, which has a density of around 0.90 g/cm³.

The choice of density for the propylene used in polypropylene production depends on the desired properties of the final product. LDPE is typically more flexible and less rigid than HDPE, while HDPE is typically stronger and more durable than LDPE. Additionally, the density of the propylene affects the weight and volume of the final product, which can impact transportation and storage costs.

To produce the desired density of propylene, various methods can be used, including fractional distillation and catalytic cracking. For example, catalytic cracking can be used to produce high-density propylene by breaking down heavier hydrocarbons into smaller fragments, including propylene. Fractional distillation can be used to separate propylene from other compounds in a mixture and produce a propylene product with a specific density.

In conclusion, the density of alkenes and alkynes plays an important role in the production of various materials, including plastics such as polypropylene. The choice of density can impact the physical properties and cost-effectiveness of the final product, and various methods can be used to achieve the desired density for a particular application.

White paper on Alkenes and Alkynes Density

Introduction:

Alkenes and alkynes are hydrocarbons with carbon-carbon double and triple bonds, respectively. The density of these compounds is an important property that affects their physical and chemical properties, as well as their production processes and applications. In this white paper, we will explore the significance of alkenes and alkynes density, including its effects on their properties, production methods, and applications.

Effects of Alkenes and Alkynes Density:

The density of alkenes and alkynes affects their physical properties, such as melting and boiling points, solubility, and viscosity. Generally, alkenes and alkynes with lower densities have lower melting and boiling points, are more soluble in nonpolar solvents, and have lower viscosity. For instance, ethene, which has a density of 0.55 g/cm³, has a melting point of -169°C and boiling point of -103°C. In contrast, propene, which has a density of 0.73 g/cm³, has a melting point of -185°C and boiling point of -47.6°C. Similarly, acetylene, which has a density of 0.91 g/cm³, has a melting point of -80.8°C and boiling point of -84°C.

Production of Alkenes and Alkynes Density:

The production of alkenes and alkynes involves various methods that affect the density of the resulting products. For instance, steam cracking is a method for producing alkenes from hydrocarbons that involves heating the hydrocarbons in the presence of steam. This process results in alkenes with relatively low densities due to the breakdown of the larger molecules into smaller fragments.

Catalytic cracking is another method for producing alkenes from hydrocarbons, and it involves heating the hydrocarbons in the presence of a catalyst. The density of the resulting alkenes can vary depending on the type of catalyst used and the reaction conditions.

Dehydrogenation is a method for producing alkynes from alkenes that involves removing hydrogen atoms from the alkene molecule. The resulting alkynes have a higher density than the original alkenes.

Acetylene, an important alkyne used in various applications, can be produced by reacting calcium carbide with water, which produces acetylene gas. The density of the acetylene gas depends on the temperature and pressure at which it is produced.

Applications of Alkenes and Alkynes Density:

The density of alkenes and alkynes affects their applications in various industries, including the production of plastics, pharmaceuticals, and petrochemicals. For example, the density of propylene, an alkene, affects the density of the resulting polypropylene, a common plastic used in a variety of applications. Low-density polypropylene (LDPE) is produced using low-density propylene, which typically has a density of around 0.88 g/cm³, while high-density polypropylene (HDPE) is produced using high-density propylene, which has a density of around 0.90 g/cm³. The choice of density for the propylene used in polypropylene production depends on the desired properties of the final product, such as flexibility, strength, and durability.

Conclusion:

In conclusion, the density of alkenes and alkynes is an important property that affects their physical and chemical properties, production processes, and applications in various industries. Understanding the effects of density on alkenes and alkynes can help optimize production processes and select appropriate materials for specific applications. Further research in this area can lead to the development of new methods and applications for these versatile hydrocarbons.