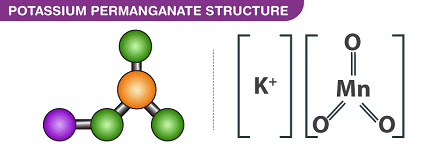

Alkenes can undergo different reactions with KMnO4 (potassium permanganate) and ozone (O3) depending on the conditions and the type of alkene.

When alkenes are treated with KMnO4 in the presence of acidic conditions, they can undergo oxidative cleavage, resulting in the formation of two carbonyl compounds (ketones or aldehydes) and a pair of manganese dioxide (MnO2) ions as byproducts. This reaction is often referred to as “cold” or “Baeyer’s” oxidation.

For example, the reaction between potassium permanganate and cyclohexene in acidic conditions can be represented as:

C6H10 + 2 KMnO4 + 3 H2SO4 → 2 MnSO4 + 2 H2O + 2 CO2 + C6H10O2

When alkenes are treated with ozone in the presence of a reducing agent (such as zinc or dimethyl sulfide), they can undergo ozonolysis, which results in the formation of aldehydes, ketones, and carboxylic acids.

For example, the reaction between ozone and ethene in the presence of zinc can be represented as:

C2H4 + O3 → C2H4O + O2 C2H4O + Zn/H2O → CH3CHO + HCOOH + ZnO

Overall, the reactions of alkenes with KMnO4 and ozone can be useful tools for the synthesis of carbonyl compounds and other organic molecules.

What is Required Reactions of alkenes with KMnO4 and Ozone

The reactions of alkenes with KMnO4 and ozone require specific conditions and reagents for them to occur.

The reaction between alkenes and KMnO4 requires acidic conditions, such as the presence of sulfuric acid (H2SO4). The acidic conditions facilitate the formation of a reactive intermediate, which allows for the oxidative cleavage of the alkene. In addition, the reaction requires the presence of KMnO4, which acts as an oxidizing agent, and results in the formation of two carbonyl compounds.

The reaction of alkenes with ozone, on the other hand, requires the presence of a reducing agent, such as zinc or dimethyl sulfide, to prevent the decomposition of the ozone. The reaction typically occurs in a non-acidic environment and results in the formation of aldehydes, ketones, and carboxylic acids.

It is important to note that the reactions of alkenes with KMnO4 and ozone are highly selective and can be used to synthesize specific carbonyl compounds and other organic molecules. Therefore, the choice of reagents and conditions used in these reactions must be carefully considered in order to achieve the desired outcome.

When is Required Reactions of alkenes with KMnO4 and Ozone

The reactions of alkenes with KMnO4 and ozone can be used in various applications in organic synthesis.

The oxidative cleavage of alkenes with KMnO4 is a useful reaction for the synthesis of carbonyl compounds such as aldehydes and ketones. This reaction can be used for the oxidation of alkenes to produce a variety of important chemicals such as carboxylic acids, alcohols, and aldehydes. For example, the Baeyer’s oxidation of cyclohexene with KMnO4 in acidic conditions produces adipic acid, which is an important precursor for the synthesis of nylon.

The ozonolysis of alkenes is another important reaction that is widely used in organic synthesis. This reaction can be used for the synthesis of aldehydes, ketones, and carboxylic acids, which are important building blocks in the chemical industry. Ozonolysis is also used for the determination of the structure of unsaturated compounds, as it results in the formation of characteristic ozonides that can be identified using spectroscopic methods.

Overall, the reactions of alkenes with KMnO4 and ozone are important tools for the synthesis of a variety of organic compounds and can be used in a wide range of applications in the chemical industry.

Where is Required Reactions of alkenes with KMnO4 and Ozone

The reactions of alkenes with KMnO4 and ozone can be carried out in a laboratory setting or in an industrial setting.

In a laboratory setting, these reactions are typically carried out in a small-scale reaction vessel, such as a round-bottom flask or a test tube, using standard laboratory equipment such as a stir plate, heating mantle, and reflux condenser.

In an industrial setting, these reactions are often carried out in large-scale reaction vessels, such as a chemical reactor, which allows for the production of large quantities of the desired product. The industrial production of chemicals using these reactions often involves the use of specialized equipment, such as pumps, heat exchangers, and distillation columns, to ensure efficient and safe operation.

The reactions of alkenes with KMnO4 and ozone can also be carried out in a variety of solvents, including water, organic solvents such as methanol, ethanol, or acetone, or a mixture of solvents to achieve the desired reaction conditions.

Overall, the reactions of alkenes with KMnO4 and ozone can be carried out in a variety of settings and with a range of equipment and solvents, depending on the desired scale and application of the reaction.

How is Required Reactions of alkenes with KMnO4 and Ozone

The reactions of alkenes with KMnO4 and ozone can be carried out using different methods, depending on the specific conditions and requirements of the reaction.

The oxidation of alkenes with KMnO4 typically involves the addition of a solution of KMnO4 to a reaction mixture containing the alkene and an acidic solution, such as sulfuric acid. The reaction mixture is then heated and stirred, often using a reflux condenser, to maintain the desired reaction conditions. The reaction is complete when the purple color of KMnO4 disappears, indicating the complete oxidation of the alkene. The reaction products can be separated and purified using standard techniques such as distillation, extraction, or chromatography.

The ozonolysis of alkenes involves the addition of a solution of ozone in a solvent such as methanol or acetone to a reaction mixture containing the alkene and a reducing agent, such as zinc or dimethyl sulfide. The reaction mixture is then stirred and allowed to react for a period of time, typically at a low temperature. The reaction products can be separated and purified using standard techniques such as distillation, extraction, or chromatography.

In both cases, the specific conditions and reagents used in the reactions must be carefully controlled to ensure the desired products are formed and to prevent unwanted side reactions. In addition, safety precautions must be taken when working with these reagents, as they can be hazardous if not handled properly.

Nomenclature of Reactions of alkenes with KMnO4 and Ozone

The reactions of alkenes with KMnO4 and ozone are classified as oxidation reactions and ozonolysis reactions, respectively.

The oxidative cleavage of alkenes with KMnO4 is often referred to as Baeyer’s oxidation, named after the German chemist Adolf von Baeyer who first described the reaction in 1884. The reaction is sometimes also referred to as the alkaline permanganate oxidation or cold potassium permanganate oxidation.

The ozonolysis of alkenes is named after the use of ozone as a reagent in the reaction. The reaction is often simply referred to as ozonolysis, but can also be referred to as ozonation or ozonlysis.

When naming specific reactions, the name of the alkene precursor is typically included, followed by the name of the reagent and the type of reaction that occurs. For example, the oxidative cleavage of cyclohexene with KMnO4 would be referred to as the Baeyer’s oxidation of cyclohexene. The ozonolysis of an alkene such as ethene would be referred to as the ozonolysis of ethene.

Overall, the nomenclature of reactions of alkenes with KMnO4 and ozone typically includes the name of the reagent and the type of reaction that occurs, along with the name of the alkene precursor when referring to specific reactions.

Case Study on Reactions of alkenes with KMnO4 and Ozone

One notable case study involving the reactions of alkenes with KMnO4 and ozone is the synthesis of adipic acid, which is a key intermediate in the production of nylon. Adipic acid is traditionally synthesized through a multistep process involving the oxidation of cyclohexene using KMnO4, followed by the ozonolysis of the resulting cyclic diol intermediate to form adipic acid. This process is often referred to as the Baeyer-Drewson process.

In the first step of the Baeyer-Drewson process, cyclohexene is oxidized using a solution of KMnO4 in an acidic environment. The double bond of the alkene is converted to a diol group, resulting in the formation of 1,2-cyclohexanediol. The reaction is typically carried out at elevated temperatures and under reflux to ensure complete oxidation of the alkene.

In the second step of the process, the cyclic diol intermediate is subjected to ozonolysis, which involves the addition of a solution of ozone in methanol to the reaction mixture. The cyclic diol is cleaved into two separate carboxylic acid groups, forming adipic acid as the final product. The reaction is typically carried out at low temperatures and under anhydrous conditions to prevent unwanted side reactions.

The Baeyer-Drewson process for the synthesis of adipic acid is a well-established industrial process, with several improvements and modifications having been developed over the years to increase efficiency and yield. For example, the use of catalysts such as cobalt or manganese can enhance the oxidation of the alkene, while the use of alternative solvents such as acetic acid can improve the yield and selectivity of the ozonolysis reaction.

Overall, the reactions of alkenes with KMnO4 and ozone are important reactions in the production of a wide range of chemicals and materials, including nylon, pharmaceuticals, and agrochemicals. The Baeyer-Drewson process for the synthesis of adipic acid is one notable example of the use of these reactions in an industrial setting.

White paper on Reactions of alkenes with KMnO4 and Ozone

Introduction

Alkenes are a class of unsaturated hydrocarbons that contain one or more double bonds. They are widely used in the production of a variety of chemicals, materials, and pharmaceuticals. Alkenes can undergo a range of reactions, including addition, oxidation, and ozonolysis. In this white paper, we will focus on the reactions of alkenes with potassium permanganate (KMnO4) and ozone (O3), which are important reactions in the synthesis of a variety of compounds.

Reactions of alkenes with KMnO4

KMnO4 is a powerful oxidizing agent that can react with alkenes to form diols or ketones. The reaction is typically carried out in an acidic medium, with the oxidation occurring at the double bond of the alkene. The product of the reaction depends on the structure of the alkene and the conditions of the reaction.

The oxidation of alkenes with KMnO4 is often referred to as the Baeyer’s oxidation or the cold potassium permanganate oxidation. The reaction has several applications in the production of chemicals and materials, including the synthesis of diols, ketones, and carboxylic acids. For example, the Baeyer’s oxidation of cyclohexene is a key step in the production of adipic acid, which is used in the production of nylon.

Reactions of alkenes with ozone

Ozone is a powerful oxidizing agent that can react with alkenes to form ozonides, which can then undergo reductive workup to form aldehydes, ketones, or carboxylic acids. The reaction is typically carried out at low temperatures and under anhydrous conditions, with the ozonolysis occurring at the double bond of the alkene.

The ozonolysis of alkenes is an important reaction in the synthesis of a variety of compounds, including pharmaceuticals, agrochemicals, and flavors. For example, the ozonolysis of limonene, a terpene found in citrus fruits, is used in the production of the flavoring agent carvone.

Comparison of reactions

Both the reactions of alkenes with KMnO4 and ozone are important in the synthesis of a variety of compounds. The Baeyer’s oxidation of alkenes with KMnO4 is typically used to produce diols, ketones, and carboxylic acids, while the ozonolysis of alkenes with ozone is typically used to produce aldehydes, ketones, and carboxylic acids. The choice of reagent and conditions for the reaction depends on the desired product and the structure of the starting alkene.

Conclusion

The reactions of alkenes with KMnO4 and ozone are important in the synthesis of a variety of compounds. The Baeyer’s oxidation of alkenes with KMnO4 is typically used to produce diols, ketones, and carboxylic acids, while the ozonolysis of alkenes with ozone is typically used to produce aldehydes, ketones, and carboxylic acids. These reactions have applications in the production of chemicals, materials, pharmaceuticals, and flavors, and are important tools for the chemical industry.