Surface energy refers to the energy required to increase the surface area of a material or object. It is a measure of the cohesive forces between the atoms or molecules in the bulk of the material and the surface atoms or molecules. The surface atoms or molecules have a higher potential energy than those in the bulk because they are not completely surrounded by other atoms or molecules, and therefore experience a net attractive force towards the bulk.

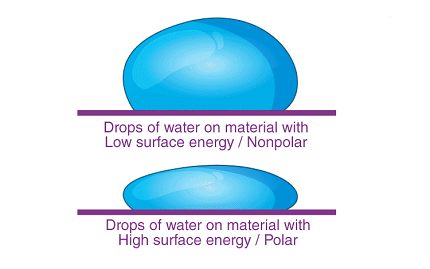

Surface energy plays an important role in various phenomena, such as wetting, adhesion, and the formation of thin films. For example, the surface tension of a liquid is related to its surface energy, and determines its ability to wet a solid surface. Similarly, the adhesion between two surfaces is dependent on their respective surface energies. A high surface energy material will have a stronger adhesion to another high surface energy material than to a low surface energy material.

Surface energy can be measured experimentally using techniques such as contact angle measurements or surface tension measurements. It is also commonly estimated using theoretical models based on the molecular structure and composition of the material.

What is Mechanics Surface Energy

Mechanics Surface Energy is a measure of the energy required to create a unit area of new surface in a material under mechanical loading or deformation. It is related to the surface tension or surface energy of the material, but it takes into account the mechanical properties of the material as well.

When a material is subjected to mechanical loading, it deforms and stores elastic energy. If a crack or a void is created in the material, this elastic energy is released, and it contributes to the surface energy of the material. The Mechanics Surface Energy is a measure of the energy required to create this new surface, taking into account the elastic energy that is released.

The Mechanics Surface Energy can be calculated using a variety of theoretical models, such as the Griffith theory or the J-integral approach. These models take into account the stress and strain distributions around a crack or a void, and determine the energy required to create new surface area in the material under mechanical loading.

The Mechanics Surface Energy is an important parameter in the study of fracture and failure of materials, as it determines the energy required to create and propagate cracks or voids in a material under mechanical loading. It is also useful in the design of materials with improved fracture resistance or in the development of coatings or surface treatments that can improve the adhesion and durability of a material under mechanical loading.

Who is Mechanics Surface Energy

“Mechanics Surface Energy” is not a person, but rather a scientific concept in the field of materials science and mechanics. It is a measure of the energy required to create a unit area of new surface in a material under mechanical loading or deformation. This energy is related to the surface tension or surface energy of the material, but it takes into account the mechanical properties of the material as well. The Mechanics Surface Energy is an important parameter in the study of fracture and failure of materials, as it determines the energy required to create and propagate cracks or voids in a material under mechanical loading. It is also useful in the design of materials with improved fracture resistance or in the development of coatings or surface treatments that can improve the adhesion and durability of a material under mechanical loading.

When is Mechanics Surface Energy

Mechanics Surface Energy is a concept that is relevant whenever a material is subjected to mechanical loading or deformation, and there is a potential for crack or void formation. This can occur in a variety of situations, such as in the design of structures or components that are subjected to mechanical stresses, in the study of fracture and failure of materials, or in the development of coatings or surface treatments to improve the durability of a material under mechanical loading.

For example, in the design of a component for a machine or vehicle, the Mechanics Surface Energy can be used to determine the energy required to create and propagate cracks in the material, and to ensure that the material has sufficient fracture resistance to withstand the expected mechanical loading. In the study of fracture and failure of materials, the Mechanics Surface Energy can be used to understand the mechanisms of crack propagation and to develop strategies for improving the fracture resistance of the material. In the development of coatings or surface treatments, the Mechanics Surface Energy can be used to evaluate the adhesion and durability of the coating or treatment under mechanical loading, and to optimize the design of the coating or treatment for maximum performance.

Where is Mechanics Surface Energy

Mechanics Surface Energy is not a physical location, but rather a scientific concept that is relevant in the study of materials science and mechanics. It describes the energy required to create a unit area of new surface in a material under mechanical loading or deformation. This energy is related to the surface tension or surface energy of the material, but it takes into account the mechanical properties of the material as well. The concept of Mechanics Surface Energy is applied in a wide range of fields, including engineering, materials science, physics, and chemistry, and is relevant wherever there is a potential for crack or void formation in a material under mechanical loading.

How is Mechanics Surface Energy

Mechanics Surface Energy can be calculated using a variety of theoretical models, such as the Griffith theory or the J-integral approach. These models take into account the stress and strain distributions around a crack or a void, and determine the energy required to create new surface area in the material under mechanical loading.

The Griffith theory is based on the assumption that a crack will propagate when the energy released by the elastic deformation of the material around the crack tip is sufficient to overcome the energy required to create new surface area. The theory assumes that the crack grows perpendicular to the direction of the maximum tensile stress, and that the energy required to create new surface area is proportional to the square of the crack length.

The J-integral approach is a more general method that can be used to calculate the Mechanics Surface Energy for cracks of arbitrary shape and orientation. The J-integral is a measure of the energy required to create a unit area of new surface at the crack tip, and can be calculated by integrating the stress and displacement fields around the crack.

Both of these methods take into account the elastic energy stored in the material under mechanical loading, and determine the energy required to create new surface area in the material under these conditions. The calculated value of Mechanics Surface Energy can be used to predict the behavior of the material under mechanical loading, and to design materials with improved fracture resistance or coatings and surface treatments with improved adhesion and durability.

Case Study on Mechanics Surface Energy

Here’s a brief case study on Mechanics Surface Energy:

A company that produces aircraft components is interested in improving the fracture resistance of a high-strength aluminum alloy used in the production of aircraft wing spars. The company has identified the formation and propagation of cracks as a critical failure mechanism, and is interested in improving the fracture toughness of the material to increase its resistance to cracking.

The company decides to use Mechanics Surface Energy as a key parameter in its efforts to improve the fracture resistance of the material. To do this, the company first performs a series of experiments to measure the mechanical properties of the material and to characterize the behavior of cracks under mechanical loading.

Using the results of these experiments, the company then uses theoretical models based on the Griffith theory and the J-integral approach to calculate the Mechanics Surface Energy for cracks of various sizes and orientations in the material. The company finds that the Mechanics Surface Energy is highest for cracks that are oriented perpendicular to the direction of maximum tensile stress, and that the energy required to create new surface area increases rapidly as the crack length increases.

Based on these findings, the company decides to develop a new alloy composition and processing method that is specifically designed to reduce the Mechanics Surface Energy of the material and to improve its fracture resistance. The company uses a combination of alloying elements and processing techniques to control the microstructure of the material and to reduce the energy required to create and propagate cracks.

After extensive testing and validation, the company finds that the new alloy composition and processing method significantly improve the fracture resistance of the material, as measured by the critical stress intensity factor and the crack propagation rate. The company attributes this improvement to the reduction in Mechanics Surface Energy achieved through the new alloy composition and processing method.

This case study demonstrates how the concept of Mechanics Surface Energy can be used to guide the development of new materials and processing methods with improved fracture resistance and durability under mechanical loading. By understanding the relationship between the mechanical properties of the material and the energy required to create and propagate cracks, the company was able to develop a targeted approach to improve the performance of the material and meet the specific needs of its application in aircraft wing spars.

White paper on Mechanics Surface Energy

Here is an overview of Mechanics Surface Energy in a white paper format:

Introduction:

Mechanics Surface Energy is a fundamental concept in the field of materials science and mechanics that describes the energy required to create a unit area of new surface in a material under mechanical loading or deformation. The concept of Mechanics Surface Energy is relevant in a wide range of fields, including engineering, materials science, physics, and chemistry, and is essential to understanding the mechanisms of fracture and failure in materials under mechanical loading.

Overview of Mechanics Surface Energy:

Mechanics Surface Energy is a measure of the energy required to create a unit area of new surface in a material under mechanical loading or deformation. It takes into account the surface tension or surface energy of the material, as well as the mechanical properties of the material, including its elastic modulus, Poisson’s ratio, and yield strength. The concept of Mechanics Surface Energy is relevant whenever a material is subjected to mechanical loading or deformation, and there is a potential for crack or void formation.

Calculation of Mechanics Surface Energy:

Mechanics Surface Energy can be calculated using a variety of theoretical models, such as the Griffith theory or the J-integral approach. These models take into account the stress and strain distributions around a crack or a void, and determine the energy required to create new surface area in the material under mechanical loading. The Griffith theory assumes that a crack will propagate when the energy released by the elastic deformation of the material around the crack tip is sufficient to overcome the energy required to create new surface area. The J-integral approach is a more general method that can be used to calculate the Mechanics Surface Energy for cracks of arbitrary shape and orientation.

Applications of Mechanics Surface Energy:

Mechanics Surface Energy is a critical parameter in the study of fracture and failure of materials, as it provides insights into the mechanisms of crack propagation and the fracture resistance of the material. It is also relevant in the design of structures or components that are subjected to mechanical stresses, as it can be used to determine the energy required to create and propagate cracks in the material and to ensure that the material has sufficient fracture resistance to withstand the expected mechanical loading. In the development of coatings or surface treatments, the Mechanics Surface Energy can be used to evaluate the adhesion and durability of the coating or treatment under mechanical loading and to optimize the design of the coating or treatment for maximum performance.

Conclusion:

Mechanics Surface Energy is a critical parameter in the study of materials science and mechanics, and is essential to understanding the mechanisms of fracture and failure in materials under mechanical loading. By understanding the relationship between the mechanical properties of the material and the energy required to create and propagate cracks, it is possible to develop new materials and processing methods with improved fracture resistance and durability under mechanical loading. The concept of Mechanics Surface Energy has broad applications in a wide range of fields, and will continue to be a key area of research in the future.