Torque is a measure of the twisting force that an object experiences when a force is applied to it. It is a vector quantity, meaning it has both magnitude and direction. In physics, torque is often denoted by the symbol “τ” and is measured in units of newton-meters (N·m) or pound-feet (lb·ft).

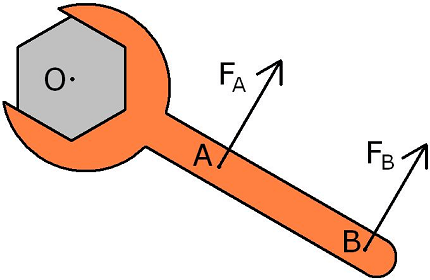

Torque is calculated by multiplying the force applied to an object by the distance from the point of application of the force to the axis of rotation. This distance is often referred to as the lever arm or moment arm. The formula for torque is:

τ = r x F

where τ is the torque, r is the length of the lever arm, and F is the force applied.

Torque is important in many areas of science and engineering, including mechanics, physics, and automotive engineering. It is used to describe the rotational motion of objects and is essential in the design and operation of many machines and mechanical systems.

What is Required Mechanics Torque

“Required mechanics torque” is a term that is not commonly used in physics or engineering. However, I can explain the concept of “required torque” in mechanical systems.

In a mechanical system, the required torque is the amount of twisting force needed to rotate a shaft or other rotating component. This torque is determined by the load on the system, the speed of rotation, and the mechanical properties of the components.

For example, in a car engine, the required torque is the amount of twisting force needed to turn the crankshaft, which in turn rotates the wheels. The amount of torque required depends on the load on the engine (i.e. the weight of the vehicle and the resistance of the road), the desired speed, and the mechanical properties of the engine components.

To ensure that a mechanical system operates properly, it is important to choose components that can handle the required torque. This includes selecting the right motor or engine, transmission, gears, and bearings. If the required torque exceeds the capacity of the components, the system may fail or break down.

When is Required Mechanics Torque

The term “required mechanics torque” is not a commonly used term in physics or engineering. However, torque is required in many mechanical systems to produce or control rotational motion. Here are some examples of when torque is required in mechanical systems:

- In engines: Torque is required to produce rotational motion in engines, such as in cars, planes, boats, or generators. The torque generated by the engine is used to drive a shaft or other rotating component, which in turn powers the vehicle or machinery.

- In machines: Many machines, such as lathes, drills, and saws, require torque to produce rotational motion. The torque is used to turn a cutting tool or other component that performs a specific task.

- In robotics: In robotic systems, torque is required to control the motion of robotic arms and other moving parts. This allows the robot to perform specific tasks with precision and accuracy.

- In industrial applications: Torque is often required in industrial settings to move heavy machinery, such as cranes or conveyor belts. The torque is used to rotate gears or other components that move the machinery.

In all of these cases, the amount of required torque will depend on the specific application, the load on the system, and the mechanical properties of the components involved.

Where is Required Mechanics Torque

The concept of “required mechanics torque” applies to mechanical systems that involve rotational motion. In such systems, torque is required to produce or control the motion of rotating components. Here are some examples of where required mechanics torque is present:

- Engines: Torque is required to produce rotational motion in engines, which are used in a wide variety of vehicles and machines. Examples include car engines, airplane engines, boat engines, and generators.

- Industrial machinery: Torque is often required in industrial settings to move heavy machinery, such as cranes, conveyors, and manufacturing equipment.

- Robotics: Torque is required in robotic systems to control the motion of robotic arms and other moving parts.

- Construction equipment: Many types of construction equipment, such as excavators, bulldozers, and backhoes, require torque to operate their rotating components.

- Household appliances: Many common household appliances, such as blenders, mixers, and washing machines, require torque to rotate their moving parts.

In all of these cases, the amount of required torque will depend on the specific application, the load on the system, and the mechanical properties of the components involved.

How is Required Mechanics Torque

The amount of required mechanics torque depends on the specific application and the mechanical properties of the system involved. In general, the required mechanics torque can be calculated using the formula:

Torque = Force x Distance

where Force is the force applied to the system, and Distance is the distance from the axis of rotation to the point where the force is applied. The units of torque are typically expressed in Newton-meters (Nm) or pound-feet (lb-ft).

Here are some examples of how required mechanics torque can be calculated:

- Car engine: The required mechanics torque in a car engine is determined by the load on the engine, the desired speed, and the mechanical properties of the engine components. The torque can be calculated using the formula above, with the force being the combustion pressure in the cylinders and the distance being the length of the crankshaft.

- Industrial machinery: In industrial machinery, the required mechanics torque is determined by the load on the system and the mechanical properties of the components. For example, in a conveyor system, the torque required to move the conveyor belt is determined by the weight of the load and the friction between the belt and the rollers.

- Robotics: In robotic systems, the required mechanics torque is determined by the desired motion of the robotic arm or other moving part. The torque can be calculated using the formula above, with the force being the weight of the load being moved and the distance being the length of the robotic arm.

In all cases, the required mechanics torque must be considered when designing and operating mechanical systems to ensure that they function properly and safely.

Structures of Mechanics Torque

Mechanics torque is a physical quantity that describes the rotational force applied to an object. It is often used in the design and analysis of structures and machines, as it can help determine the stress and strain on the components involved. Here are some structures where mechanics torque is an important factor:

- Beams: In a beam, mechanics torque can cause bending stress, which can lead to failure if the torque is too high. Beams are often designed with a specific allowable stress based on the amount of torque that is expected to be applied.

- Shafts: Shafts are used in many machines to transmit torque from one component to another. The strength and durability of the shaft are determined by the amount of torque it must withstand.

- Gears: Gears are used to transmit torque and rotational motion between two components. The size and strength of the gears are determined by the amount of torque that must be transmitted.

- Bolts: Bolts are used to secure components together and can be subjected to torque when the components are in motion. The strength of the bolts must be sufficient to withstand the applied torque.

- Bearings: Bearings are used to support rotating components and can be subjected to torque when the component rotates. The bearings must be designed to withstand the applied torque and reduce friction.

In all of these structures, mechanics torque plays an important role in determining the strength, durability, and reliability of the components. Understanding the mechanics of torque is crucial for designing and analyzing these structures to ensure they operate safely and efficiently.

Case Study on Mechanics Torque

One real-world example of how mechanics torque can be used in engineering design and analysis is in the development of wind turbines. Wind turbines use wind power to generate electricity by rotating a set of blades that are connected to a generator. The torque applied to the blades by the wind is a critical factor in the design and operation of wind turbines.

In wind turbines, the amount of torque applied to the blades is determined by the wind speed, the size and shape of the blades, and the mechanical properties of the rotor and generator components. To maximize the efficiency of the turbine, it is important to design the rotor blades to withstand the applied torque without bending or breaking.

In the design process, engineers use computer simulations and physical testing to evaluate the effects of different wind speeds and loads on the rotor blades. These simulations and tests allow engineers to optimize the design to ensure that the blades can withstand the expected torque and operate efficiently.

During operation, wind turbines are also subjected to varying wind speeds and loads, which can cause fluctuations in the applied torque. To prevent damage to the blades and other components, wind turbines are equipped with sensors and control systems that adjust the angle and speed of the rotor blades to maintain a steady torque and prevent overloading.

In summary, the mechanics of torque play a crucial role in the design and operation of wind turbines. Understanding the effects of applied torque on the mechanical components of the turbine allows engineers to design and optimize these systems for maximum efficiency and reliability.

White paper on Mechanics Torque

Introduction

Mechanics torque is a physical quantity that describes the rotational force applied to an object. It is a fundamental concept in engineering design and analysis, as it can help determine the stress and strain on the components involved. This white paper will provide an overview of mechanics torque, its properties, and its applications in engineering.

What is Mechanics Torque?

Mechanics torque is defined as the product of the force applied to an object and the distance from the axis of rotation at which the force is applied. Mathematically, it is expressed as:

Torque = Force x Distance

The units of torque are typically expressed in Newton-meters (Nm) or pound-feet (lb-ft).

Properties of Mechanics Torque

There are several properties of mechanics torque that are important to understand, including:

- Direction: The direction of mechanics torque is perpendicular to both the applied force and the axis of rotation.

- Magnitude: The magnitude of mechanics torque is proportional to the applied force and the distance from the axis of rotation.

- Moment arm: The distance from the axis of rotation to the point of force application is called the moment arm, and it plays a critical role in determining the magnitude of the mechanics torque.

Applications of Mechanics Torque

Mechanics torque is a critical factor in the design and analysis of many engineering systems, including:

- Automotive engineering: In automobiles, mechanics torque is used to describe the rotational force applied to the wheels by the engine. It is also used to design and analyze other components, such as the transmission and differential.

- Aerospace engineering: In aerospace engineering, mechanics torque is used to describe the rotational force applied to aircraft components, such as the wings and propellers.

- Robotics: In robotics, mechanics torque is used to describe the rotational force applied to the robotic arm and other moving parts.

- Industrial machinery: In industrial machinery, mechanics torque is used to design and analyze components such as shafts, gears, and bearings.

Conclusion

In conclusion, mechanics torque is a fundamental concept in engineering design and analysis. Understanding the properties and applications of mechanics torque is crucial for designing and analyzing mechanical systems to ensure they function properly and safely. From automotive engineering to aerospace engineering, robotics, and industrial machinery, mechanics torque plays a critical role in determining the strength, durability, and reliability of the components involved.