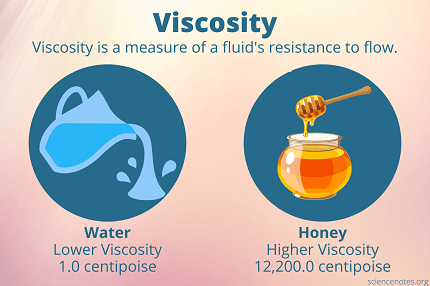

Viscosity is a measure of a fluid’s resistance to flow. In simpler terms, it is the internal friction between different layers of fluid as they move past each other.

Viscosity is commonly measured in units of poise or centipoise, and is dependent on factors such as temperature, pressure, and composition of the fluid.

Fluids with high viscosity, such as honey or molasses, flow slowly and have a thicker consistency. On the other hand, fluids with low viscosity, such as water or gasoline, flow easily and have a thinner consistency.

Viscosity plays an important role in various fields, such as engineering, chemistry, and biology. For example, it is important in determining the flow rate of fluids through pipes, designing lubricants for machinery, and understanding the movement of blood through vessels in the human body.

What is Required Viscosity

Required viscosity refers to the specific viscosity that is necessary for a particular application or process.

For example, in the field of lubrication, the required viscosity of a lubricant depends on the operating conditions of the machinery or equipment that it is being used for. If the viscosity is too low, it may not provide adequate lubrication and result in increased wear and tear on the machinery. If the viscosity is too high, it can cause increased friction and heat buildup, which can also lead to damage.

In the field of chemical engineering, the required viscosity of a fluid may depend on the specific process being performed, such as mixing or pumping, and the desired flow rate. If the viscosity is too low, the fluid may not mix or pump properly, while if it is too high, it may cause clogging or flow issues.

Determining the required viscosity for a particular application typically involves considering various factors such as the operating conditions, flow rate, and desired performance characteristics, and selecting a fluid with a viscosity that meets those requirements.

When is Required Viscosity

“Required viscosity” is a term used in the context of fluid dynamics and engineering to describe the specific viscosity that is needed for a particular application or process. The time when required viscosity is considered is during the design and selection phase of a process or application.

For example, if a particular process involves pumping a fluid through a pipeline, the required viscosity of the fluid must be determined to ensure that it can be pumped effectively without causing issues such as clogging or excessive wear on the equipment. Similarly, if a lubricant is being selected for a specific type of machinery, the required viscosity of the lubricant must be considered to ensure that it provides adequate lubrication without causing excessive friction or heat buildup.

In summary, the concept of required viscosity is considered during the design and selection phase of a process or application to ensure that the fluid being used has the appropriate viscosity for the specific requirements of that process.

Nomenclature of Viscosity

The nomenclature of viscosity depends on the unit of measurement used to express it. The most common units of measurement for viscosity are Poise (P) and centipoise (cP).

- Poise (P): This is the unit of measurement for viscosity in the CGS (centimeter-gram-second) system. One Poise is defined as the viscosity of a fluid that requires a force of one dyne to move one square centimeter of area at a velocity of one centimeter per second. Poise is not commonly used in industry, but it is used in scientific and academic settings.

- Centipoise (cP): This is the most common unit of measurement for viscosity in industry. One centipoise is equal to one millipascal-second (mPa·s). Centipoise is used because it is easier to work with in practical applications than Poise.

Another common unit of measurement for viscosity is the kinematic viscosity, which is expressed in units of centistokes (cSt). Kinematic viscosity is defined as the ratio of dynamic viscosity to density and is often used in applications where fluid flow rates are important, such as in hydraulic systems.

In addition to these standard units of measurement, there are also several alternative units of measurement for viscosity, such as Saybolt Universal Seconds (SUS) and Redwood seconds. However, these alternative units are not widely used and are primarily used in specific industries, such as petroleum production.

Where is Required Viscosity Gases and Liquids

The concept of viscosity applies to both gases and liquids. Viscosity is a measure of a fluid’s resistance to flow, and it is influenced by factors such as temperature, pressure, and the composition of the fluid. The viscosity of a gas or liquid is typically measured in units of Poise or centipoise.

In gases, viscosity is generally lower than in liquids, and it is strongly influenced by the temperature and pressure of the gas. At high pressures and low temperatures, gases tend to have higher viscosities, while at low pressures and high temperatures, gases tend to have lower viscosities.

In liquids, viscosity is generally higher than in gases, and it is strongly influenced by factors such as temperature, pressure, and the composition of the liquid. For example, the addition of viscosity modifiers or thickeners can increase the viscosity of a liquid.

In both gases and liquids, the required viscosity depends on the specific application and the desired performance characteristics of the fluid in that application. For example, in a gas pipeline, the gas must have a viscosity that is appropriate for the pipeline’s diameter and pressure to ensure proper flow and minimize pressure drop. In a liquid coating application, the liquid must have a viscosity that is suitable for the desired coverage and application rate.

In summary, the concept of viscosity applies to both gases and liquids, and the required viscosity depends on the specific application and the desired performance characteristics of the fluid in that application. Factors such as temperature, pressure, and the composition of the fluid must be considered when determining the required viscosity.

How is Required Viscosity

The required viscosity of a fluid is determined by the specific application and the desired performance characteristics of the fluid in that application. Viscosity is a measure of a fluid’s resistance to flow, and it can be influenced by factors such as temperature, pressure, and the composition of the fluid.

To determine the required viscosity for a particular application, it is important to consider the operating conditions of the system, such as the temperature and shear rates that the fluid will be exposed to. For example, in a hydraulic system, the fluid must have a viscosity that is appropriate for the operating temperature and the pressure levels of the system, while in a coating application, the fluid must have a viscosity that is suitable for the desired coverage and application rate.

Viscosity can be measured using a viscometer, which is an instrument that measures the force required to move a fluid through a tube of a known size and length. The viscosity of a fluid can also be affected by additives, such as viscosity modifiers or thickeners, which can be used to adjust the fluid’s viscosity to the desired level for a particular application.

In summary, the required viscosity of a fluid is determined by the specific application and the desired performance characteristics of the fluid in that application. Factors such as temperature, pressure, and the composition of the fluid must be considered when determining the required viscosity, and viscosity can be measured using a viscometer or adjusted using additives.

Case Study on Viscosity

Sure, here’s a case study on viscosity:

Case Study: Viscosity in a Chocolate Manufacturing Process

A chocolate manufacturer is experiencing problems with the viscosity of their chocolate during the manufacturing process. The chocolate is too thick, which is causing issues with the mixing and molding processes, and resulting in products that are not meeting their quality standards. The manufacturer wants to investigate the viscosity of the chocolate and determine if changes can be made to the process to improve the viscosity and quality of the final products.

The manufacturer starts by measuring the viscosity of the chocolate using a viscometer. They find that the chocolate has a viscosity of 80 centipoise at the temperature and shear rate of their manufacturing process. This is higher than the ideal viscosity range for their process, which is 50-70 centipoise.

The manufacturer investigates possible causes of the high viscosity and identifies several factors that may be contributing to the problem. These include:

- Temperature: The manufacturer realizes that the chocolate is being heated to a temperature that is too high, which is causing it to thicken and become more viscous. They decide to lower the temperature of the chocolate to the ideal temperature range for their process, which is 40-45°C.

- Fat content: The manufacturer realizes that the fat content of the chocolate may be too high, which can cause it to thicken and become more viscous. They decide to adjust the fat content of the chocolate by using a different blend of cocoa butter and other fats.

- Particle size: The manufacturer realizes that the particle size of the cocoa powder and sugar in the chocolate may be too large, which can cause it to thicken and become more viscous. They decide to adjust the particle size of the ingredients to improve the flow properties of the chocolate.

After making these changes, the manufacturer measures the viscosity of the chocolate again and finds that it has decreased to the ideal range of 50-70 centipoise. They also find that the mixing and molding processes are improved, and the final products are meeting their quality standards.

In conclusion, the manufacturer was able to address the viscosity issues in their chocolate manufacturing process by measuring the viscosity, identifying possible causes of the high viscosity, and making changes to the process to improve the viscosity and quality of the final products. This demonstrates the importance of understanding viscosity in manufacturing processes and the potential impact it can have on product quality and performance.

White paper on Viscosity

Here’s a white paper on viscosity:

Title: Understanding Viscosity and its Importance in Manufacturing Processes

Abstract:

Viscosity is a key property of fluids that plays a critical role in many manufacturing processes. It is a measure of a fluid’s resistance to flow and is influenced by factors such as temperature, pressure, and composition. Understanding viscosity is important for optimizing manufacturing processes and ensuring product quality.

This white paper provides an overview of viscosity, including its definition, measurement, and factors that affect it. We also discuss the importance of viscosity in manufacturing processes and provide examples of how it can impact product quality and performance.

Introduction:

Viscosity is a measure of a fluid’s resistance to flow, and it is an important property in many manufacturing processes. The viscosity of a fluid can be influenced by factors such as temperature, pressure, and composition, and understanding these factors is critical for optimizing manufacturing processes and ensuring product quality.

Definition of Viscosity:

Viscosity is defined as the resistance of a fluid to flow. It is measured in units of Poise or centipoise and is determined by the internal friction of the fluid. High-viscosity fluids have a greater resistance to flow than low-viscosity fluids, and this can have significant impacts on manufacturing processes and product quality.

Measurement of Viscosity:

Viscosity can be measured using a viscometer, which is an instrument that measures the force required to move a fluid through a tube of a known size and length. There are several types of viscometers, including capillary, rotational, and falling ball viscometers, and the choice of viscometer depends on the specific application and the properties of the fluid being measured.

Factors that Affect Viscosity:

Viscosity is influenced by several factors, including temperature, pressure, and composition. For example, the viscosity of a fluid generally decreases with increasing temperature, while it may increase with increasing pressure. The composition of the fluid can also impact viscosity, with fluids containing high molecular weight compounds generally having higher viscosities than fluids containing lower molecular weight compounds.

Importance of Viscosity in Manufacturing Processes:

Viscosity plays a critical role in many manufacturing processes, and understanding its importance is essential for optimizing processes and ensuring product quality. For example, in a coating application, the viscosity of the fluid must be appropriate for the desired coverage and application rate, while in a hydraulic system, the fluid must have a viscosity that is appropriate for the operating temperature and pressure levels of the system.

Impact of Viscosity on Product Quality and Performance:

The viscosity of a fluid can have a significant impact on product quality and performance. For example, in a food processing application, the viscosity of a sauce can impact its texture and mouthfeel, while in a pharmaceutical application, the viscosity of a drug formulation can impact its efficacy and dosing.

Conclusion:

Viscosity is a critical property of fluids that plays an important role in many manufacturing processes. Understanding viscosity and its impacts on product quality and performance is essential for optimizing processes and ensuring consistent, high-quality products.