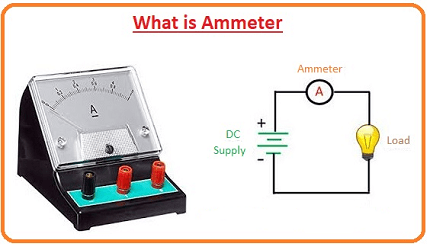

An ammeter is a device used to measure the electric current in a circuit. It is typically connected in series with the circuit, which means that the current flows through the ammeter itself. The unit of measurement for electric current is the ampere (A), so an ammeter will measure the current in amperes.

Ammeters are commonly used in a variety of settings, from industrial applications to educational laboratories. They come in both analog and digital forms, with analog ammeters typically using a needle and a scale to display the current, while digital ammeters display the value on a digital screen.

It’s important to note that ammeters should be connected correctly in a circuit to avoid damaging them or the circuit itself. They should also have a suitable range for the expected current being measured to ensure accurate readings.

What is Required Ammeter

A required ammeter refers to the specific ammeter that is needed for a particular application or circuit. The required ammeter should be able to accurately measure the current flowing through the circuit, and its range should be suitable for the maximum current that is expected to flow.

When selecting a required ammeter, it is important to consider factors such as the type of circuit, the voltage level, and the expected current range. For example, if the circuit operates at a high voltage level, a high-voltage ammeter may be required. Similarly, if the circuit carries a high current, a high-current ammeter may be necessary.

It’s also important to consider the accuracy of the ammeter, as well as its resolution (i.e. the smallest increment of current that can be accurately measured). In addition, the ammeter should be compatible with the circuit and connected properly in series with the load, so that it does not cause a significant drop in voltage or introduce any resistance to the circuit.

Overall, selecting the correct required ammeter is crucial for obtaining accurate and reliable current measurements in a circuit.

When is Required Ammeter

A required ammeter is needed whenever there is a need to measure the electric current flowing through a circuit. This can be in a variety of settings, from industrial applications to educational laboratories.

For example, in an industrial setting, a required ammeter may be used to measure the current flowing through a large motor or other electrical equipment. This information can be used to monitor the equipment’s performance, diagnose any issues, and ensure that it is operating within safe limits.

In a laboratory setting, a required ammeter may be used in experiments or demonstrations to measure the current flowing through various circuits. This can help students or researchers understand the behavior of electric current and how it relates to different components and configurations of a circuit.

A required ammeter may also be used in electrical troubleshooting to diagnose problems in a circuit. By measuring the current at various points in the circuit, it may be possible to identify faulty components or other issues that are affecting the circuit’s performance.

Overall, a required ammeter is necessary whenever accurate current measurements are needed for a circuit or electrical system.

Where is Required Ammeter

A required ammeter can be located in various places depending on the application and the circuit being measured. In most cases, the ammeter is connected in series with the load (i.e. the component or components that the current is flowing through) so that all of the current flowing through the load also flows through the ammeter.

In some cases, the ammeter may be integrated into a piece of equipment or machinery, such as a motor control panel or a power supply unit. In this case, the ammeter may be a built-in feature of the equipment, or it may be an optional accessory that can be added to the equipment.

In other cases, a standalone ammeter may be used that can be connected to the circuit using test leads or other connectors. These standalone ammeters may be handheld devices, benchtop instruments, or part of a larger measurement system.

In addition, some ammeters may be designed for specific applications, such as clamp meters that can measure current without physically breaking the circuit. These clamp meters can be attached to the outside of a wire or cable, and they use magnetic fields to measure the current flowing through the wire without making a physical connection to it.

Overall, the location of a required ammeter will depend on the application and the specific measurement requirements of the circuit being measured.

How is Required Ammeter

To use a required ammeter, it must be properly connected in series with the circuit that is being measured. This means that the ammeter must be inserted into the circuit so that all of the current flowing through the load (i.e. the component or components being powered) also flows through the ammeter.

The exact procedure for connecting the ammeter will depend on the type of ammeter being used and the specific circuit being measured. In general, however, the steps for using a required ammeter are as follows:

- Turn off power to the circuit to prevent electric shock or damage to the ammeter.

- Identify the point in the circuit where the ammeter should be connected. This is typically at a point where the current flow is highest.

- Open the circuit at this point so that the ammeter can be inserted in series.

- Connect the ammeter in series with the circuit, using appropriate connectors or test leads. Make sure the ammeter is connected with the correct polarity.

- Close the circuit and turn on the power.

- Read the current measurement on the ammeter display. If necessary, adjust the range or resolution of the ammeter to obtain a more accurate reading.

- Turn off power to the circuit and disconnect the ammeter when the measurement is complete.

It’s important to note that ammeters must be properly rated for the expected current and voltage levels of the circuit being measured, and they must be handled with care to avoid damage or injury.

Structures of Ammeter

The structure of an ammeter can vary depending on the type and application of the ammeter. However, in general, an ammeter is designed to measure the electrical current flowing through a circuit and typically consists of the following basic components:

- Moving coil: This is a coil of wire that is suspended within a magnetic field. As current flows through the coil, it generates a magnetic field that interacts with the external magnetic field, causing the coil to rotate.

- Damping mechanism: To prevent the coil from oscillating or swinging excessively, a damping mechanism is typically included. This can be a mechanical device, such as a dashpot, or an electrical device, such as a resistor or capacitor.

- Scale: The ammeter scale is used to display the current measurement, typically in amperes (A). The scale may be calibrated in various units, depending on the specific application.

- Calibration adjustment: To ensure accuracy, the ammeter may include a calibration adjustment that can be used to adjust the zero or full-scale reading of the instrument.

- Shunt: In some cases, a shunt may be included in the ammeter to allow it to measure high currents. The shunt is a low-resistance element that is connected in parallel with the ammeter, diverting a portion of the current away from the ammeter and through the shunt.

- Housing: The ammeter may be enclosed in a protective housing that provides insulation and mechanical support.

Overall, the structure of an ammeter is designed to accurately measure the current flowing through a circuit while minimizing any interference or disruption to the circuit. Different types of ammeters, such as moving-iron, moving-coil, or clamp meters, may have different structures and operating principles, but they all aim to perform the same basic function of measuring current.

Case Study on Ammeter

Here is a case study on how an ammeter was used to diagnose a problem in an electrical circuit:

A maintenance technician was called to a manufacturing plant to investigate an issue with a conveyor belt system that had suddenly stopped working. The technician began by visually inspecting the system and found that the conveyor belt was not moving and that there was no power going to the motor.

To diagnose the problem, the technician used an ammeter to measure the current flowing through the circuit that powered the motor. He first disconnected the motor from the circuit to avoid any danger of electrical shock, and then connected the ammeter in series with the circuit.

When the technician turned on the power, he saw that the ammeter reading was zero, indicating that there was no current flowing through the circuit. This meant that the problem was not with the motor, but rather with the power supply or the wiring.

The technician then began to trace the wiring back from the motor to the power supply. He found that one of the wires had become disconnected from the terminal block, preventing the circuit from completing and allowing current to flow to the motor.

After reattaching the wire and verifying that the connection was secure, the technician used the ammeter again to measure the current flowing through the circuit. This time, the ammeter showed a reading of several amps, indicating that the motor was receiving power and was ready to run.

The technician then turned on the conveyor belt system and observed that the motor started running and the conveyor belt began moving again. The problem had been resolved, and the system was back up and running.

In this case, the ammeter was an essential tool that allowed the technician to quickly diagnose the problem with the circuit and identify the root cause of the issue. Without the ammeter, it would have been much more difficult to determine where the problem was and how to fix it, potentially leading to a longer downtime and increased costs for the manufacturing plant.

White paper on Ammeter

Introduction:

An ammeter is a fundamental electrical instrument used for measuring the flow of electric current through a circuit. The ability to measure current is essential for any electrical system, and ammeters are widely used in a variety of applications, from household electrical systems to industrial automation.

This white paper will cover the basic principles of ammeters, their types, working, and applications.

Principles of Ammeters:

An ammeter is based on the principle of the interaction between magnetic fields generated by an electric current flowing through a conductor and an external magnetic field. The ammeter typically consists of a current-carrying coil suspended within a magnetic field. The magnitude of the magnetic field generated by the current in the coil is proportional to the current flowing through the conductor, and the deflection of the coil is proportional to the magnitude of the magnetic field.

Types of Ammeters:

There are several types of ammeters, including moving-coil, moving-iron, and digital ammeters. Moving-coil ammeters are the most common type, and they work by suspending a coil of wire within a magnetic field. Moving-iron ammeters use a ferromagnetic material instead of a coil, and digital ammeters use electronic circuitry to measure current.

Working of Ammeters:

To measure the current flowing through a circuit, an ammeter must be connected in series with the load, i.e., the component or components being powered. This means that all the current flowing through the load must also flow through the ammeter. When the current flows through the coil of the ammeter, it generates a magnetic field that interacts with the external magnetic field, causing the coil to rotate. The rotation of the coil is proportional to the current flowing through the circuit, and the ammeter scale is calibrated to display the current reading.

Applications of Ammeters:

Ammeters are used in a variety of applications, including:

- Electrical systems: Ammeters are used in household and industrial electrical systems to measure the current flowing through the circuit.

- Automotive systems: Ammeters are used in automotive systems to measure the current flowing through the battery and the charging system.

- Power generation and distribution: Ammeters are used in power generation and distribution systems to measure the current flowing through the generators, transformers, and transmission lines.

- Industrial automation: Ammeters are used in industrial automation systems to monitor and control the current flowing through motors, actuators, and other components.

Conclusion:

Ammeters are essential tools for measuring the flow of electric current in various applications. They are simple and reliable instruments that provide accurate readings of current, allowing engineers and technicians to troubleshoot and optimize electrical systems. With the advent of digital ammeters, the accuracy and convenience of measuring current have improved further. In summary, ammeters play a critical role in electrical systems and are indispensable for maintaining and optimizing the performance of these systems.