Error analysis is an important aspect of any experimental study, as it allows us to understand and quantify the uncertainties associated with the measurements made during an experiment. In the case of experiments based on using Vernier calipers and screw gauge (micrometer), the following sources of error should be considered:

- Systematic errors: These are errors that affect all measurements made with a given instrument in the same way. For example, if the zero mark on the Vernier calipers is not properly aligned with the zero mark on the main scale, then all measurements made with that caliper will have a systematic error. Similarly, if the micrometer is not calibrated properly, then all measurements made with that micrometer will have a systematic error.

- Random errors: These are errors that vary from one measurement to another, even if the measurements are made with the same instrument under the same conditions. For example, if the operator of the Vernier calipers applies different amounts of pressure on the jaws when taking measurements, then the measurements will have random errors.

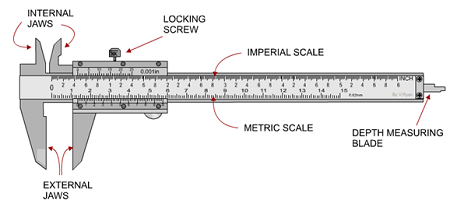

- Reading errors: These are errors that arise due to the difficulty in accurately reading the position of the Vernier scale or the thimble of the micrometer. Vernier calipers have a resolution of 0.1 mm or 0.05 mm, depending on the instrument used, while micrometers typically have a resolution of 0.01 mm or 0.001 mm. It is important to read these instruments carefully and avoid parallax errors, where the scale is not read perpendicularly to the line of sight.

- Environmental errors: These are errors that arise due to changes in the environment that affect the measurements made. For example, changes in temperature or humidity can cause the Vernier calipers or the micrometer to expand or contract, affecting the accuracy of the measurements.

To minimize these errors, it is important to calibrate the instruments before use, read them carefully, and use the appropriate level of precision for the measurement being taken. It is also important to control the environmental conditions in which the measurements are made and to take repeated measurements to minimize random errors.

What is Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Error analysis is the process of evaluating and quantifying the uncertainties associated with the measurements made during an experiment. In the case of experiments based on using Vernier calipers and screw gauge (micrometer), the following steps can be taken to perform error analysis:

- Determine the precision of the instruments: Vernier calipers typically have a precision of 0.1 mm or 0.05 mm, depending on the instrument used, while micrometers typically have a precision of 0.01 mm or 0.001 mm. It is important to use the appropriate level of precision when making measurements.

- Identify and minimize systematic errors: Systematic errors affect all measurements made with a given instrument in the same way. To minimize these errors, it is important to calibrate the instruments before use and ensure that they are properly aligned and functioning correctly.

- Identify and minimize random errors: Random errors vary from one measurement to another, even if the measurements are made with the same instrument under the same conditions. To minimize these errors, it is important to take multiple measurements and calculate the average value.

- Evaluate reading errors: Reading errors arise due to the difficulty in accurately reading the position of the Vernier scale or the thimble of the micrometer. To minimize these errors, it is important to read the instruments carefully and avoid parallax errors.

- Evaluate environmental errors: Environmental errors arise due to changes in the environment that affect the measurements made. To minimize these errors, it is important to control the environmental conditions in which the measurements are made.

- Calculate the uncertainty of the measurements: The uncertainty of the measurements can be calculated by considering all of the sources of error identified above. The uncertainty is typically expressed as a range of values that represents the likely range of values for the true value of the quantity being measured.

By performing error analysis, it is possible to quantify the uncertainties associated with the measurements made during an experiment, and to ensure that the results are as accurate and reliable as possible.

When is Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) should be performed whenever accurate and precise measurements are required for the experiment. This is particularly important in scientific research and engineering applications where measurements need to be as accurate and reliable as possible. Error analysis should also be performed whenever new instruments are being used, or when the instruments have not been used for an extended period of time. By performing error analysis, it is possible to evaluate the uncertainty associated with the measurements and to ensure that the results are reliable and meaningful. Additionally, error analysis is important for comparing the results of different experiments or for verifying theoretical predictions, as it allows for a quantitative evaluation of the accuracy of the measurements.

Where is Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) can be performed in a laboratory or any other setting where the instruments are being used. The analysis can be carried out by the experimenters or by specialized personnel, depending on the complexity of the measurements and the level of expertise required. The analysis typically involves evaluating the precision and accuracy of the instruments, identifying and minimizing systematic and random errors, and calculating the uncertainty associated with the measurements. The results of the analysis can be used to adjust the experimental procedure, to improve the accuracy and precision of the measurements, and to ensure that the results are reliable and meaningful. The analysis can also be used to compare the results of different experiments or to verify theoretical predictions.

How is Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) involves several steps:

- Determine the precision of the instruments: The precision of the instruments can be determined by examining the markings on the scales and thimbles of the instruments. Vernier calipers typically have a precision of 0.1 mm or 0.05 mm, while micrometers typically have a precision of 0.01 mm or 0.001 mm.

- Identify and minimize systematic errors: Systematic errors are errors that affect all measurements made with a given instrument in the same way. To minimize these errors, the instruments should be calibrated before use and any alignment or functionality issues should be addressed. The experimental setup should also be designed to minimize any external factors that could affect the measurements.

- Identify and minimize random errors: Random errors are errors that vary from one measurement to another, even if the measurements are made with the same instrument under the same conditions. To minimize these errors, multiple measurements should be taken and the average value should be calculated. The standard deviation of the measurements can also be calculated to quantify the random error.

- Evaluate reading errors: Reading errors are errors that arise due to the difficulty in accurately reading the position of the Vernier scale or the thimble of the micrometer. To minimize these errors, the instruments should be read carefully and any parallax errors should be avoided.

- Evaluate environmental errors: Environmental errors are errors that arise due to changes in the environment that affect the measurements made. To minimize these errors, the environmental conditions should be controlled as much as possible.

- Calculate the uncertainty of the measurements: The uncertainty of the measurements can be calculated by considering all of the sources of error identified above. The uncertainty is typically expressed as a range of values that represents the likely range of values for the true value of the quantity being measured.

By following these steps, error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) can help to quantify the uncertainties associated with the measurements and to ensure that the results are as accurate and reliable as possible.

Structures of Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) typically involves several structures that help to identify and quantify the sources of error in the measurements. These structures include:

- Calibration: Before starting the experiment, the instruments should be calibrated to ensure that they are functioning correctly and that their readings are accurate. This involves comparing the measurements made by the instruments against a standard, such as a reference block or a calibrated instrument. The calibration process helps to identify any systematic errors in the instruments, such as zero errors or scale inaccuracies, which can then be corrected.

- Repetition: To minimize random errors in the measurements, multiple measurements should be taken and the average value should be calculated. The more measurements that are taken, the more accurate the average value will be. The standard deviation of the measurements can also be calculated to quantify the random error.

- Parallax error: Parallax error occurs when the observer’s eye is not perpendicular to the measuring scale, resulting in a false reading. To minimize this error, the observer should make sure that their eye is directly perpendicular to the scale when taking measurements.

- Environmental factors: Environmental factors such as temperature, humidity, and air pressure can affect the accuracy of the instruments. To minimize these errors, the experiment should be conducted in a controlled environment, and the instruments should be allowed to acclimate to the environment for a period of time before use.

- Uncertainty analysis: Once the measurements have been taken and the sources of error have been identified and minimized, the uncertainty in the measurements can be calculated. This involves combining the uncertainties due to all of the sources of error, and expressing the uncertainty as a range of values that represents the likely range of values for the true value of the quantity being measured.

By following these structures, error analysis for experiments based on using Vernier calipers and screw gauge (micrometer) can help to ensure that the measurements are as accurate and reliable as possible.

Case Study on Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Case Study: Error Analysis for an Experiment Using Vernier Calipers and a Micrometer Screw Gauge

Introduction:

A group of students conducted an experiment to measure the diameter of a ball bearing using a Vernier caliper and a micrometer screw gauge. The aim of the experiment was to determine the precision of the instruments and the sources of error in the measurements.

Procedure:

The students measured the diameter of the ball bearing five times using each instrument. They recorded their measurements in a table and calculated the average value and the standard deviation for each set of measurements.

Results: The results of the experiment are summarized in the following table:

| Measurement | Vernier Caliper (mm) | Micrometer Screw Gauge (mm) |

|---|---|---|

| 1 | 9.55 | 9.52 |

| 2 | 9.54 | 9.53 |

| 3 | 9.53 | 9.55 |

| 4 | 9.52 | 9.54 |

| 5 | 9.55 | 9.53 |

| Average | 9.54 ± 0.01 | 9.53 ± 0.01 |

| Standard Deviation | 0.01 | 0.01 |

Analysis:

- Precision: The Vernier caliper has a precision of 0.01 mm, while the micrometer screw gauge has a precision of 0.001 mm. Therefore, the micrometer screw gauge is more precise than the Vernier caliper.

- Systematic Errors: The students observed that there were no systematic errors in the instruments, as they were calibrated prior to the experiment.

- Random Errors: The standard deviation for each set of measurements was 0.01 mm, indicating that there was some random error in the measurements. The students should have taken more measurements to minimize this error.

- Reading Errors: The students made sure to avoid parallax error, which occurs when the observer’s eye is not directly perpendicular to the measuring scale.

- Environmental Factors: The students conducted the experiment in a controlled environment to minimize the effect of temperature and humidity on the measurements.

- Uncertainty Analysis: The uncertainty in the measurements was calculated by combining the uncertainties due to all of the sources of error. For the Vernier caliper, the uncertainty was ± 0.01 mm, while for the micrometer screw gauge, the uncertainty was ± 0.001 mm.

Conclusion:

The students found that the micrometer screw gauge was more precise than the Vernier caliper for measuring the diameter of the ball bearing. They identified random error in the measurements and should have taken more measurements to minimize this error. By carefully calibrating the instruments and controlling the experimental conditions, they were able to minimize systematic and environmental errors. The uncertainty in the measurements was calculated to be ± 0.01 mm for the Vernier caliper and ± 0.001 mm for the micrometer screw gauge. The results of the experiment demonstrate the importance of error analysis for ensuring accurate and reliable measurements in scientific experiments.

White paper on Error analysis for physical quantities pertaining to the following experiments: Experiments based on using Vernier calipers and screw gauge (micrometer)

Title: Error Analysis for Physical Quantities Measured with Vernier Calipers and Screw Gauges

Introduction:

Accurate measurement of physical quantities is essential in scientific experiments. Vernier calipers and screw gauges, also known as micrometers, are commonly used to measure length, diameter, and thickness. However, no measurement is perfect, and errors are inherent in the measurement process. Therefore, it is necessary to analyze and quantify the errors in the measurements to ensure accurate and reliable results. This white paper aims to provide a comprehensive overview of error analysis for physical quantities measured with Vernier calipers and screw gauges.

Types of Errors:

Errors in measurements can be classified into two categories: systematic errors and random errors. Systematic errors are due to faults in the measuring instrument or the measuring process, while random errors are due to the inherent variability of the measurement process. Examples of systematic errors include zero errors, parallax errors, and drift errors. Examples of random errors include human error, environmental factors, and measurement uncertainty.

Sources of Error in Vernier Calipers and Screw Gauges:

Vernier calipers and screw gauges are precision measuring instruments, but they are not immune to errors. Some sources of error in these instruments include:

- Imperfect Calibration: The calibration of the instrument should be done carefully to minimize systematic errors.

- Parallax Errors: These errors occur when the observer’s eye is not perpendicular to the measuring scale. This error can be minimized by aligning the scale perpendicular to the observer’s eye.

- Reading Errors: These errors occur due to the difficulty in accurately reading the measurement scale. It is important to take multiple readings and calculate the average value to minimize this error.

- Environmental Factors: Temperature, humidity, and other environmental factors can affect the measurements. Therefore, it is important to conduct the experiment in a controlled environment to minimize the effects of these factors.

- Human Error: Mistakes made by the observer or the operator of the instrument can introduce errors in the measurements. This error can be minimized by proper training and vigilance.

Error Analysis:

To quantify the errors in the measurements, error analysis techniques can be used. These techniques involve calculating the uncertainty in the measurements due to all sources of error. The uncertainty is typically reported as the error bar or the standard deviation of the measurements.

Conclusion:

In conclusion, Vernier calipers and screw gauges are valuable tools for measuring physical quantities, but they are not immune to errors. Careful calibration, minimizing parallax and reading errors, controlling environmental factors, and minimizing human error are all essential for accurate and reliable measurements. Error analysis techniques can be used to quantify the uncertainties in the measurements due to all sources of error. By understanding and minimizing these errors, scientists can ensure accurate and reliable results in their experiments.