Natural rubber is a type of elastomer that is derived from the latex of various tropical plants, primarily the Hevea brasiliensis tree. The latex is harvested by making incisions in the bark of the tree and collecting the milky fluid that flows out. This fluid contains small, elastic globules of rubber, which can be processed into various products.

Natural rubber is an important industrial material due to its unique combination of properties. It is highly elastic, which means it can stretch and return to its original shape without deforming or breaking. It is also highly resistant to abrasion, tear, and puncture, which makes it ideal for use in products that need to withstand wear and tear, such as tires, hoses, and conveyor belts.

However, natural rubber is susceptible to degradation when exposed to heat, light, and certain chemicals. To address this, it is often blended with other materials, such as synthetic rubber or carbon black, to enhance its performance.

Natural rubber is an important commodity that is traded on international markets. The largest producers of natural rubber are Thailand, Indonesia, and Vietnam.

What is Required Polymers Natural Rubber

“Required Polymers” in relation to natural rubber. However, natural rubber is itself a polymer, specifically a polymer of isoprene. The polymer chains of natural rubber are made up of repeating units of isoprene molecules.

Natural rubber can be processed and blended with other materials to create a wide range of polymers with different properties and applications. For example, it can be blended with synthetic rubbers, such as styrene-butadiene rubber (SBR) or polybutadiene rubber (PBR), to create materials with enhanced properties, such as improved resistance to heat and chemicals.

Additionally, natural rubber can be chemically modified to create different polymers. For example, it can be chlorinated or brominated to create materials with improved flame retardant properties.

Overall, natural rubber is an important raw material for the production of a variety of polymers used in many industries, including automotive, construction, and consumer goods.

When is Polymers Natural Rubber

Natural rubber is a polymer itself, made up of repeating units of isoprene molecules. However, natural rubber can also be used as a starting material to create other polymers. For example, natural rubber can be chemically modified or blended with other materials to create new polymers with different properties.

Here are some examples of when natural rubber is used to create other polymers:

- Styrene-butadiene rubber (SBR): SBR is a synthetic rubber that is made by blending natural rubber with styrene and butadiene. SBR is used in a wide range of applications, including tires, footwear, and industrial products.

- Polyisoprene: Polyisoprene is a synthetic rubber that is very similar in structure to natural rubber. It is made by polymerizing isoprene monomers, which are similar to the isoprene molecules found in natural rubber. Polyisoprene is used in a variety of applications, including medical gloves and balloons.

- Chlorinated polyethylene (CPE): CPE is a thermoplastic polymer that is made by chlorinating high-density polyethylene (HDPE) in the presence of natural rubber. CPE is used in a variety of applications, including wire and cable insulation, automotive parts, and industrial products.

Overall, natural rubber can be used as a starting material to create a wide range of polymers with different properties and applications.

Where is Polymers Natural Rubber

Polymers made from natural rubber can be found in a wide range of products and applications. Here are a few examples:

- Tires: Natural rubber is a key component of many tire formulations. It provides excellent traction, wear resistance, and low rolling resistance.

- Footwear: Natural rubber is used to make a variety of footwear, including sneakers, sandals, and rain boots. Natural rubber soles provide good grip and durability.

- Industrial products: Natural rubber is used in a variety of industrial products, including conveyor belts, hoses, and gaskets. Its high elasticity and resistance to abrasion make it well-suited for these applications.

- Medical products: Natural rubber is used to make medical gloves, syringe plungers, and other medical products. Its high elasticity and low allergenicity make it a good choice for these applications.

- Consumer products: Natural rubber is used in many consumer products, including balloons, erasers, and toys. Its low cost and versatility make it a popular choice for these applications.

Overall, polymers made from natural rubber can be found in a wide range of products and industries, making it an important material in the global economy.

How is Polymers Natural Rubber

Polymers made from natural rubber can be created through various processes, depending on the desired properties and application of the final product. Here are a few common methods:

- Polymer blending: Natural rubber can be blended with other materials to create new polymers with enhanced properties. For example, natural rubber can be blended with synthetic rubbers, such as styrene-butadiene rubber (SBR) or polybutadiene rubber (PBR), to improve properties such as heat resistance, abrasion resistance, or elasticity.

- Chemical modification: Natural rubber can be chemically modified to create new polymers with different properties. For example, natural rubber can be chlorinated or brominated to create materials with improved flame retardant properties.

- Vulcanization: Vulcanization is a process that involves heating natural rubber with sulfur or other cross-linking agents to create a more stable polymer. The cross-links between polymer chains improve the elasticity and durability of the final product.

- Latex coagulation: Natural rubber is harvested from the latex of the Hevea brasiliensis tree, which contains small, elastic globules of rubber suspended in a milky fluid. Latex can be coagulated with acid or other agents to separate the rubber from the liquid, which can then be processed into various products.

Overall, the process of creating polymers from natural rubber can involve blending, chemical modification, cross-linking, and other techniques, depending on the desired properties of the final product.

Structures of Polymers Natural Rubber

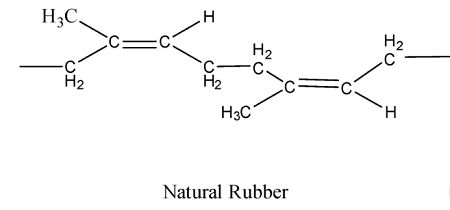

Polymers made from natural rubber have a specific chemical structure that is determined by the repeating unit of isoprene monomers that make up the polymer chain. Natural rubber is a polymer of isoprene, which is a hydrocarbon with the molecular formula C5H8.

The structure of natural rubber can be represented as follows:

- The repeating unit of natural rubber is made up of two isoprene monomers, which are linked together through a carbon-carbon double bond.

- The resulting polymer chain is a long, flexible molecule with a backbone made up of alternating carbon-carbon single bonds and double bonds.

- The double bonds in the polymer chain give natural rubber its unique elasticity and ability to recover its original shape after being stretched.

- The presence of double bonds also makes natural rubber susceptible to degradation over time, as the double bonds can react with oxygen in the air and break down.

In addition to the polymer structure, natural rubber can also contain impurities such as proteins, lipids, and other non-rubber components that are present in the latex of the Hevea brasiliensis tree. These impurities can affect the properties and processing of the final product, and are often removed or reduced through various refining processes.

Case Study on Polymers Natural Rubber

One example of a case study on the use of polymers made from natural rubber is the application of natural rubber in the tire industry.

Tires are one of the most common and important applications of natural rubber. Natural rubber is used in the tread, sidewalls, and other components of tires to provide a combination of traction, durability, and ride comfort. The properties of natural rubber make it well-suited for tire applications, including its high elasticity, low heat buildup, and resistance to wear and tear.

However, natural rubber is also subject to supply and price fluctuations, as the majority of the world’s natural rubber is produced in a limited number of countries, such as Thailand, Indonesia, and Malaysia. In recent years, there have been concerns about the sustainability and social impacts of natural rubber production, including deforestation, labor rights violations, and environmental damage.

As a result, tire manufacturers have been exploring alternative materials and sources of natural rubber to reduce their reliance on traditional sources. One example is the use of synthetic rubber blends, such as styrene-butadiene rubber (SBR), as a replacement or supplement to natural rubber. These blends can provide similar properties to natural rubber, while also reducing the environmental impact and price volatility associated with natural rubber.

In addition, some tire manufacturers have been exploring the use of alternative sources of natural rubber, such as guayule and Russian dandelion. These plants produce a type of natural rubber that is similar in structure and properties to Hevea brasiliensis, but can be grown in different regions and under different conditions. The development of these alternative sources of natural rubber could provide a more sustainable and diversified supply chain for the tire industry.

Overall, the case study of natural rubber in the tire industry highlights the importance of sustainability and diversification in the use of polymers made from natural rubber. As demand for natural rubber continues to grow, it will be important to find new and innovative ways to produce, source, and use this important material in a sustainable and responsible manner.

White paper on Polymers Natural Rubber

Here is a white paper on Polymers Natural Rubber:

Introduction:

Natural rubber is a versatile polymer that is widely used in a variety of industries, including automotive, construction, and consumer goods. Polymers made from natural rubber have unique properties, including high elasticity, resilience, and low heat buildup, which make them well-suited for applications such as tires, hoses, and seals.

This white paper provides an overview of natural rubber polymers, including their properties, production, and applications. It also discusses the challenges and opportunities associated with the use of natural rubber polymers, and explores some of the emerging trends and technologies that are shaping the future of this important material.

Properties:

Polymers made from natural rubber have a specific chemical structure that is determined by the repeating unit of isoprene monomers that make up the polymer chain. The resulting polymer chain is a long, flexible molecule with a backbone made up of alternating carbon-carbon single bonds and double bonds. The presence of double bonds gives natural rubber its unique elasticity and ability to recover its original shape after being stretched. In addition, natural rubber has a low heat buildup, which makes it ideal for applications such as tires.

Production:

Natural rubber is harvested from the latex of the Hevea brasiliensis tree, which is native to South America but is now primarily grown in Southeast Asia. The latex is collected by making small incisions in the bark of the tree, which allows the latex to flow out and be collected in cups. The latex is then treated with a coagulating agent, such as formic acid or acetic acid, which causes the rubber particles to clump together and separate from the liquid.

Once the rubber has been separated from the liquid, it is washed, pressed, and dried to remove impurities and moisture. The resulting natural rubber is then processed into various forms, including sheets, blocks, or pellets, depending on the intended application.

Applications:

Polymers made from natural rubber are used in a variety of applications, including:

- Tires: Natural rubber is a key component of tire treads, providing traction and durability.

- Industrial hoses and seals: Natural rubber is used to make flexible hoses and seals that can withstand high pressures and temperatures.

- Medical devices: Natural rubber is used in a variety of medical devices, such as gloves and catheters.

- Consumer goods: Natural rubber is used in a variety of consumer goods, such as toys, footwear, and clothing.

Challenges and opportunities:

One of the main challenges associated with the use of natural rubber polymers is the supply chain. The majority of the world’s natural rubber is produced in a limited number of countries, such as Thailand, Indonesia, and Malaysia. This concentration of production can lead to price volatility and supply chain disruptions.

Another challenge is the environmental impact of natural rubber production. The conversion of natural habitats to rubber plantations can lead to deforestation, habitat loss, and biodiversity loss. In addition, natural rubber production can be resource-intensive, requiring large amounts of water, energy, and fertilizer.

Despite these challenges, there are also opportunities to improve the sustainability and resilience of the natural rubber industry. For example, there is growing interest in alternative sources of natural rubber, such as guayule and Russian dandelion, which can be grown in different regions and under different conditions. In addition, there is interest in developing new processing techniques, such as enzymatic processing, which could reduce the environmental impact of natural rubber production.

Conclusion:

In conclusion, polymers made from natural rubber are an essential material with unique properties that make them suitable for various applications. The production of natural rubber is primarily dependent on a limited number of countries, which can lead to supply chain disruptions and price volatility. Additionally, natural rubber production can have significant environmental impacts, including deforestation and habitat loss. However, there are opportunities to improve the sustainability and resilience of the natural rubber industry by exploring alternative sources of natural rubber and developing new processing techniques. As demand for natural rubber continues to grow, it is important to find innovative ways to produce and use this material in a responsible and sustainable manner.