The simplest model of a capacitor consists of two thin parallel conductive plates each with an area of

Since the separation between the plates is uniform over the plate area, the electric field between the plates

Therefore, in a capacitor the highest capacitance is achieved with a high permittivity dielectric material, large plate area, and small separation between the plates.

Since the area

A parallel plate capacitor can only store a finite amount of energy before dielectric breakdown occurs. The capacitor’s dielectric material has a dielectric strength Ud which sets the capacitor’s breakdown voltage at V = Vbd = Udd. The maximum energy that the capacitor can store is therefore

The maximum energy is a function of dielectric volume, permittivity, and dielectric strength. Changing the plate area and the separation between the plates while maintaining the same volume causes no change of the maximum amount of energy that the capacitor can store, so long as the distance between plates remains much smaller than both the length and width of the plates. In addition, these equations assume that the electric field is entirely concentrated in the dielectric between the plates. In reality there are fringing fields outside the dielectric, for example between the sides of the capacitor plates, which increase the effective capacitance of the capacitor. This is sometimes called parasitic capacitance. For some simple capacitor geometries this additional capacitance term can be calculated analytically. It becomes negligibly small when the ratios of plate width to separation and length to separation are large.

For unevenly charged plates:

- If one plate is charged with

while the other is charged with

, and if both plates are separated from other materials in the environment, then the inner surface of the first plate will have

, and the inner surface of the second plated will have −�1−�22

charge. [citation needed] Therefore, the voltage

between the plates is

. Note that the outer surface of both plates will have

, but those charges don’t affect the voltage between the plates.

- If one plate is charged with

while the other is charged with

, and if the second plate is connected to ground, then the inner surface of the first plate will have

, and the inner surface of the second plated will have

. Therefore, the voltage

between the plates is

. Note that the outer surface of both plates will have zero charge.

What is Parallel plate capacitor

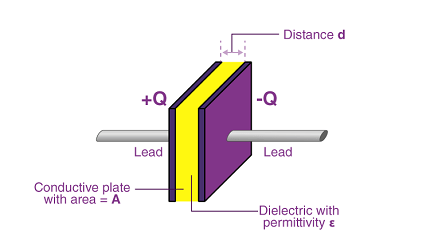

A parallel plate capacitor is a type of capacitor that consists of two parallel conductive plates separated by a small distance, known as the gap or the separation distance. The plates can be made of any conducting material such as metal or a conductive polymer.

When a voltage is applied across the plates, an electric field is created between them. This electric field causes charges to accumulate on the surface of the plates, creating an electric potential difference between the plates. The capacitance of the parallel plate capacitor is determined by the area of the plates, the distance between them, and the dielectric constant of the material between the plates.

The parallel plate capacitor is commonly used in electronic circuits as a component to store electrical energy. It has a high capacitance per unit area, making it useful in applications where a large capacitance is required in a small space. Examples of applications of parallel plate capacitors include power supplies, signal filters, and energy storage systems.

When is Parallel plate capacitor

A parallel plate capacitor can be used in a wide range of applications, such as in electronic circuits, energy storage devices, and in scientific experiments. Here are some examples of when a parallel plate capacitor might be used:

- In electronic circuits: Parallel plate capacitors are used in many electronic circuits to store and release electrical energy. They can be used in power supplies to smooth out voltage fluctuations, or in filters to remove unwanted frequencies from signals.

- In energy storage devices: Parallel plate capacitors can be used in energy storage systems to store electrical energy. They have a high power density, which means that they can store a large amount of energy in a small space, making them useful in applications where space is limited.

- In scientific experiments: Parallel plate capacitors are often used in scientific experiments to study the behavior of electric fields and charges. They can be used to create a uniform electric field, which can be used to study the behavior of charged particles.

Overall, parallel plate capacitors are versatile components that can be used in a wide range of applications where electrical energy storage and manipulation are required.

Where is Parallel plate capacitor

Parallel plate capacitors can be found in a wide range of applications, including:

- Electronics: Parallel plate capacitors are commonly used in electronic circuits, including power supplies, filters, and amplifiers.

- Energy storage: Parallel plate capacitors are used in energy storage devices such as electric vehicles, hybrid vehicles, and uninterruptible power supplies.

- Medical devices: Parallel plate capacitors are used in medical devices such as defibrillators and pacemakers.

- Research: Parallel plate capacitors are used in scientific experiments to study the behavior of electric fields and charges.

- Industrial applications: Parallel plate capacitors are used in a variety of industrial applications, such as in electroplating, metal coating, and electrostatic painting.

- Communication systems: Parallel plate capacitors are used in communication systems such as radio frequency (RF) filters and antennas.

In general, parallel plate capacitors can be found in any application where electrical energy storage or manipulation is required.

How is Parallel plate capacitor

A parallel plate capacitor is constructed by placing two parallel conductive plates close to each other but not touching, and separating them by a dielectric material. Here’s how it works:

- Conductive Plates: The two plates of the capacitor are typically made of a conductive material such as metal or a conductive polymer. The plates are placed parallel to each other, and are electrically isolated from each other.

- Dielectric Material: A dielectric material is placed between the two plates. This can be air, vacuum, or a material with a high dielectric constant such as ceramic, plastic, or glass.

- Charging: When a voltage is applied across the two plates, an electric field is created between them. Electrons in the conductive plates are pushed away from each other, and accumulate on opposite sides of the plates. This creates a separation of charge and an electric potential difference between the plates.

- Capacitance: The capacitance of the parallel plate capacitor is determined by the surface area of the plates, the distance between them, and the dielectric constant of the material between them. The capacitance can be increased by increasing the surface area of the plates or by decreasing the distance between them.

- Energy Storage: The parallel plate capacitor can store electrical energy in the electric field between the two plates. When the capacitor is charged, energy is stored in the electric field. This energy can be discharged back into the circuit when the capacitor is connected to a load.

Overall, a parallel plate capacitor works by storing electrical energy in the electric field between two parallel plates separated by a dielectric material. It is a simple yet important component in many electronic circuits and energy storage systems.

Structures of Parallel plate capacitor

The basic structure of a parallel plate capacitor consists of two parallel plates that are separated by a distance, with a dielectric material between them. Here are some of the common types of parallel plate capacitor structures:

- Parallel plate capacitors with solid dielectric: In this type of capacitor, the dielectric material is a solid material such as plastic, ceramic or glass. The two plates are typically made of metal and are flat, with a distance between them that is determined by the thickness of the dielectric material.

- Parallel plate capacitors with air dielectric: In this type of capacitor, the dielectric material is air or a vacuum. The two plates are typically made of metal and are separated by a small distance. This type of capacitor is used in high-frequency circuits, as air is a good insulator at high frequencies.

- Rolled parallel plate capacitors: In this type of capacitor, the two plates are rolled up together with a dielectric material in between. This type of capacitor is commonly used in small electronic devices, such as cameras and hearing aids, where space is limited.

- Multilayer parallel plate capacitors: In this type of capacitor, multiple parallel plate capacitors are stacked together with a dielectric material between them. This increases the capacitance per unit area and allows for higher capacitance in a smaller size.

Overall, the structure of a parallel plate capacitor depends on the application and the required capacitance, voltage rating, and size. The basic principle of two parallel plates separated by a dielectric material remains the same in all structures.

Case Study on Parallel plate capacitor

One example of a practical application of parallel plate capacitors is in energy storage systems for electric vehicles (EVs).

In an EV, a parallel plate capacitor can be used in conjunction with a battery to improve the power density and efficiency of the energy storage system. The parallel plate capacitor is typically used as a buffer between the battery and the motor, which allows for rapid discharge of energy when needed, and also helps to smooth out voltage fluctuations.

The parallel plate capacitor used in an EV energy storage system is typically a multi-layer ceramic capacitor (MLCC). MLCCs are made up of multiple layers of parallel plates separated by a dielectric material, which allows for high capacitance in a small size.

The use of a parallel plate capacitor in an EV energy storage system can improve the efficiency of the system, as it reduces the stress on the battery and allows for rapid charging and discharging of energy. It also helps to extend the life of the battery, as the capacitor can handle short bursts of high power without putting excessive strain on the battery.

One example of an EV that uses a parallel plate capacitor in its energy storage system is the Tesla Model S. The Model S uses a 85 kWh lithium-ion battery pack in combination with a parallel plate capacitor to provide high power and energy density. The use of the parallel plate capacitor helps to improve the acceleration and overall performance of the vehicle.

Overall, the use of parallel plate capacitors in energy storage systems for EVs is just one example of how this technology can be used to improve the efficiency and performance of a range of applications.

White paper on Parallel plate capacitor

Introduction:

A parallel plate capacitor is a simple yet important electronic component used in a wide range of applications, from energy storage to signal filtering. This white paper aims to provide a comprehensive overview of parallel plate capacitors, including their basic principles, structure, and applications.

Basic Principles:

A parallel plate capacitor consists of two parallel plates that are separated by a distance, with a dielectric material between them. When a voltage is applied across the two plates, an electric field is created between them, which causes the electrons in the conductive plates to move and accumulate on opposite sides of the plates. This creates a separation of charge and an electric potential difference between the plates. The capacitance of the parallel plate capacitor is determined by the surface area of the plates, the distance between them, and the dielectric constant of the material between them.

Structure:

The basic structure of a parallel plate capacitor consists of two parallel plates that are separated by a distance, with a dielectric material between them. The two plates are typically made of a conductive material such as metal or a conductive polymer, and are electrically isolated from each other. The dielectric material can be air, vacuum, or a material with a high dielectric constant such as ceramic, plastic, or glass. Other types of parallel plate capacitor structures include rolled capacitors and multilayer capacitors.

Applications:

Parallel plate capacitors are used in a wide range of applications, including energy storage, filtering, and tuning circuits. They are commonly used in power supplies, signal processing circuits, and communication systems. In energy storage systems, parallel plate capacitors can be used to improve the efficiency and performance of batteries, as they can handle short bursts of high power without putting excessive strain on the battery. In filtering circuits, parallel plate capacitors can be used to block or pass certain frequencies, depending on their capacitance and frequency response.

Conclusion:

Parallel plate capacitors are a versatile and important component in many electronic circuits and systems. Their simple yet effective structure allows for high capacitance and energy storage in a small size, making them ideal for a wide range of applications. As technology advances, the use of parallel plate capacitors will continue to grow and evolve, driving innovation in the field of electronics and energy storage.